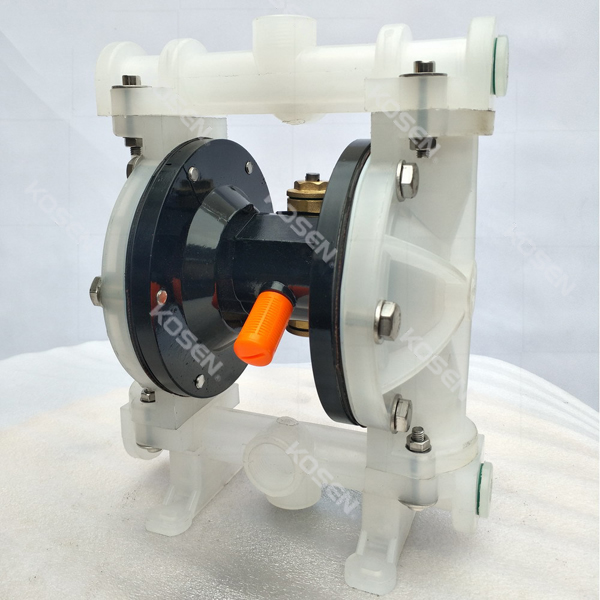

Stainless Steel Diaphragm Pump

QBY3 pneumatic diaphragm pump is my company developed the third generation of pneumatic diaphragm pump , with reliable quality and long service life , the noise at the end, vibration, never crash , fine workmanship six major advantage that it can be pumped liquid flows , but also transport some of the easy flow of the medium , has many advantages transportation machinery pump, submersible pumps , shielding pumps, mud and trash pumps.

Advantages

» no irrigation water , suction lift up to 5 meters , lift up to 70 m , the outlet pressure ≧ 7bar;

» mobile spacious , good performance , allowing the maximum particle diameter of 10 mm . Pumping mud, impurity , minimal wear and tear on the pump ;

» head, flow stepless adjustment can be achieved through the valve opening degree ( pressure adjustment between the 1-7bar);

» the pump with no moving parts, no shaft seals , diaphragm pumps and other pumping medium with moving parts , completely separated from the working medium , the transmission medium does not leak out . So pumping toxic , volatile or corrosive media, will not cause environmental pollution and danger to personal safety ;

» do not have electricity, the use of safe and reliable in flammable and explosive places ;

» the work can be immersed in the medium ;

» easy to use , reliable, open to stop simply open and close the gas valve , even for a long time because of accident or sudden stop running no media will not result in damage to the pump , once the overload , the pump will automatically shut down , a self- protective properties , when the load back to normal, and can automatically start running ;

» simple structure, less wearing parts , the pump structure is simple to install , easy maintenance, medium conveyed by the pump does not come into contact with the valve , linkage and other moving parts , unlike other types of pumps due to the rotor , pistons , gears wear performance blades and other parts of leaving the gradual decline ;

» can transport more viscous liquid ( viscosity 10,000 cps or less ) ;

» the lubricating oil pump is not required , if idling , and no effect on the pump , which is a major feature of the pump ;

» plastic flange pressure : PN0.6MPa (10bar), metal flange pressure : PN1.0MPa (10bar).