Key Specifications / Features

- Model No.: KV-20241231-HPBV-01

- Hits: 22

- Categories: High Performance Butterfly Valve

- Tags: High Performance Butterfly Valve, ASTM B148 C95800 Butterfly Valve, 3 Inch Butterfly Valve

Detail Information

Product Name: ASTM B148 C95800 High Performance Butterfly Valve

Features: Bi-directional Design, Blow-out Proof Shaft, Double Offset

Design Standard: API 609 Category B

Body Material: ASTM B148 C95800, Nickel Aluminium Bronze

Size: 3 Inch, DN80

Pressure: Class 150 LB, PN20

End Connection: Lug

Operation: Lever

The double offset high-performance butterfly valve in bronze is designed for versatility and durability, making it suitable for a wide range of applications. Its bi-directional flow design, along with a blow-out-proof shaft, ensures reliable performance under even the most challenging conditions. The valve is highly customizable, with a range of seat options available—soft seat, metal seat, or fire-safe seat—allowing for enhanced compatibility with specific customer requirements. This flexibility makes it ideal for diverse industries and environments. With its robust construction and customizable features, this valve provides an efficient and reliable solution for flow control across various industrial sectors.

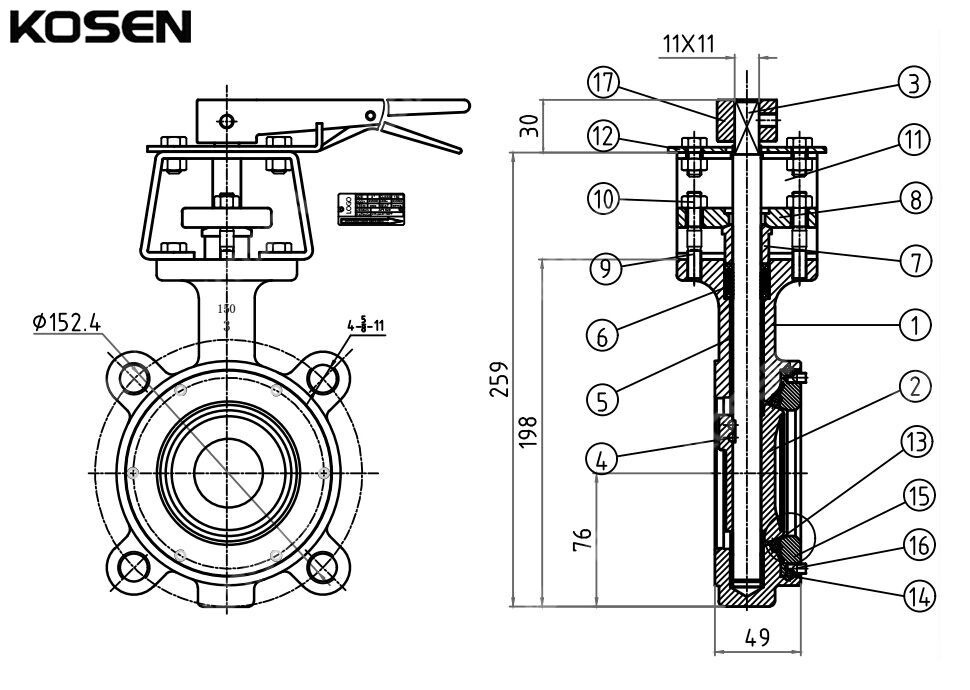

Technical Specifications

» Design: Double Offset Type

» Size Range:

Class 150 LB: 2-48 Inch

Class 300 LB: 2-48 Inch

Class 600 LB: 2-24 Inch

» Pressure Rating: Class 150-600 LB, PN10-PN40, 10K-20K

» Standard: API 609 Category B

» Body Material: Aluminium Bronze (ASTM B148 C95800, C83600, B584 C84400, ASTM B62)

» Disc Material: Aluminium Bronze (ASTM B148 C95800, C83600, B584 C84400, ASTM B62)

» Shaft Material: MONEL K500

» Shutoff Rating: Class VI, Bubble Tight

» Certifications: API 607, PED

» Valve Seat Design: Unique Valve Seat Design with optional seating materials

» Optional Seatings: RTFE (Resilient)

» Operation Types: Handle, Worm Gear, Pneumatic, Electric

» Temperature Range:

Soft Seat: -29°C to 260°C

Metal Seat: -51°C to 550°C

Metal Seat (Cryogenic): -196°C to 121°C

Fire-Safe Seat: -51°C to 550°C

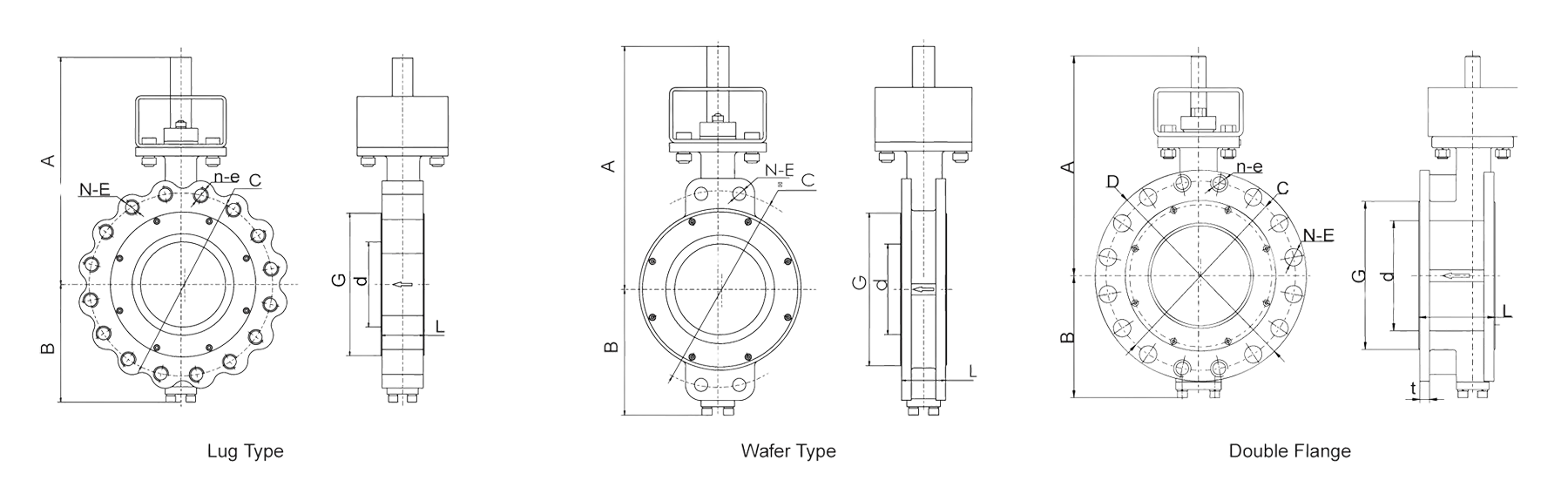

» End Connections: Wafer, Lug, RF Flange

Application Scope

» Chemical & Petrochemical: Liquefied Gas, Refrigeration

» Heavy Industrial: Power and Co-Generation Plants, Steel and Iron Works

» Commercial: Pulp and Paper Mills, Oil Refineries

» Marine & Shipbuilding: Hydrocarbon Processing, Gas Piping, Local Area Energy Supply

» Construction: Industrial and Marine Applications

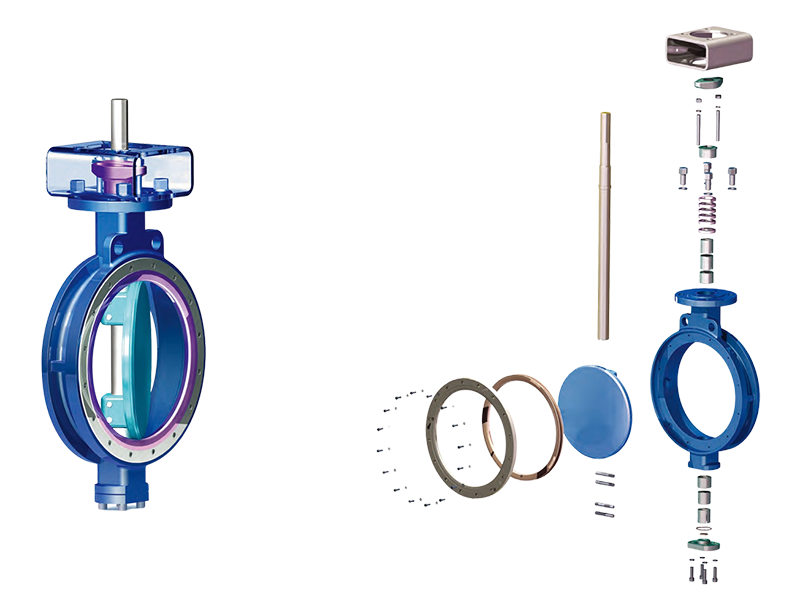

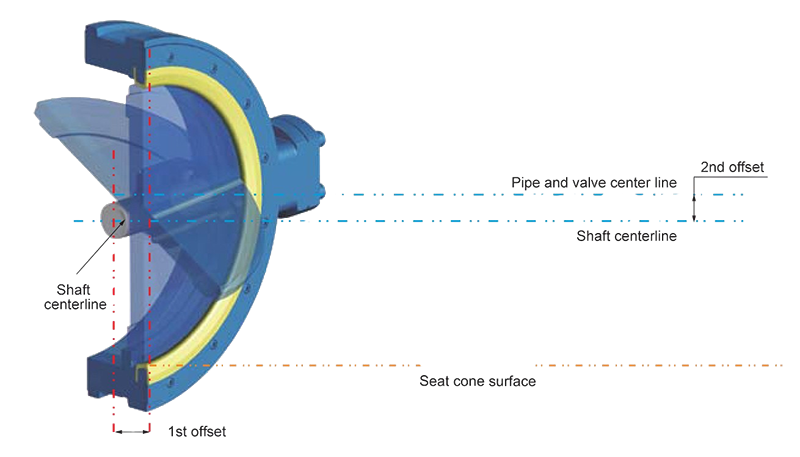

Double Offset Butterfly Valve

The Double Offset High-Performance Butterfly Valve is a new type of butterfly valve designed by absorbing the advantages of several different structural butterfly valves. The sealing surface of the valve plate is a spherical arc surface. The sealing mechanism achieves a true dynamic seal through system pressure, thus providing reliable sealing performance and durability. It features a small volume, light weight, wide manufacturing range, and is easy to maintain and repair. Due to its double offset butterfly plate design and single-piece flexible lip-shaped sealing seat, it is ideal for applications requiring reliable sealing and good regulating characteristics. It can be used for quick shut-off or regulating flow.

Double Offset Frictionless Design

- 1st offset: Shaft is positioned downstream from the centerline of the seat.

- 2nd offset: Shaft is off center from the vertical axis of the seat.

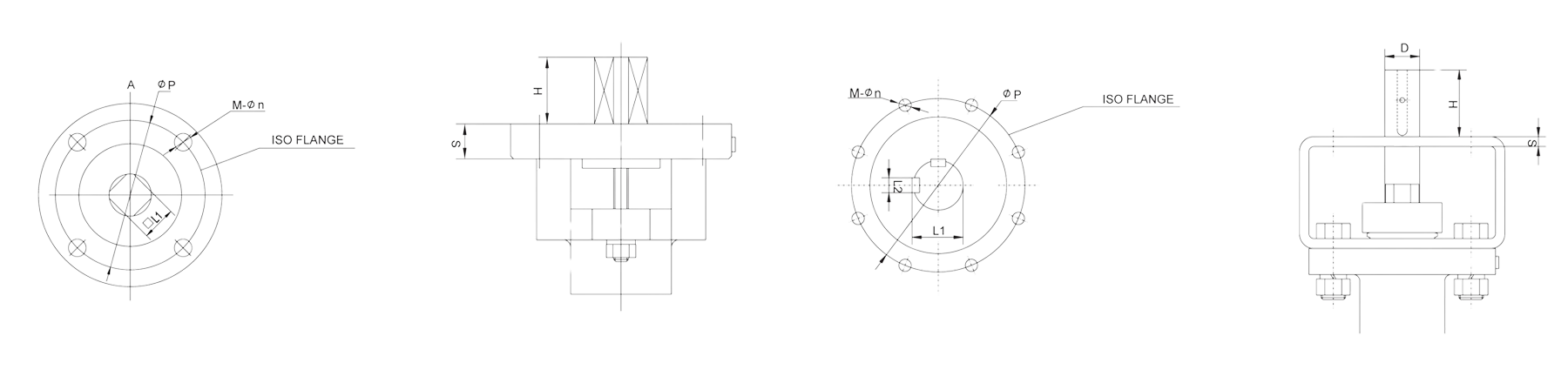

- ISO 5211 Top Flange

- In addition to standard, durable V-ring packing, you can also choose from optional graphite

- high temperature packing or emissions control packing.

- Bi-Directional, Shut off performance

- Seat Options: Rubber, PTFE, RPTFE, or Fire Safe PTFE

- The double offset operating principle minimizes seat wear and lowers operating torque to

- improve durability.

- Positive sealing is mechanically achieved and does not rely on line pressure assistance.

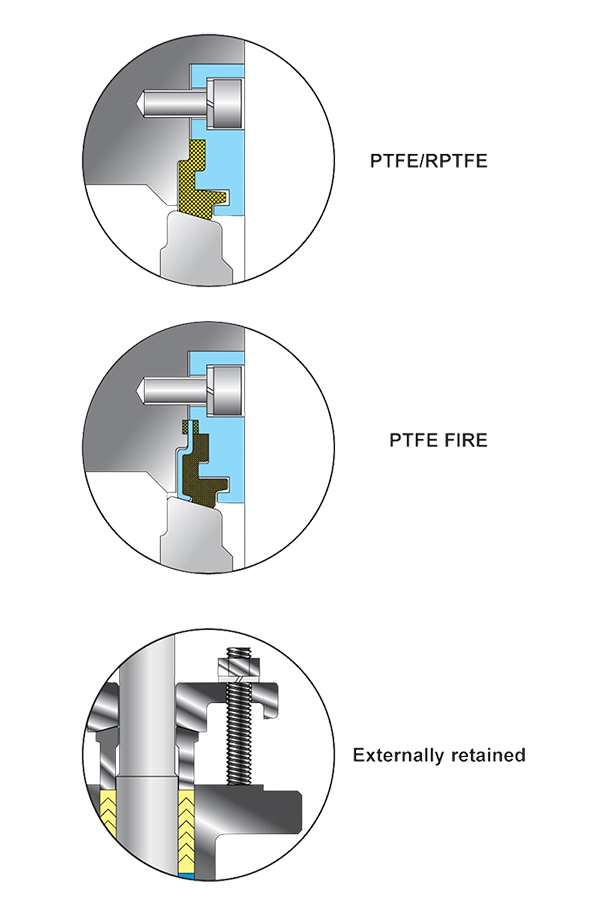

Seat Structure

Double Offset PTFE Seat Butterfly Valve

- A surplus of material between the PTFE Seat and Disc ensures a reliable seal in a low pressure environment.

- In high pressure situations, the force of the medium pushes against the seat contacting the sealing surface for a stronger seal.

- The disc surface has a conical design to reduce frictional force. The valve seat can also be replaced or repaired easily.

Double Offset Fire Safe PTFE Butterfly Valve

- Fire Safe valve seat with dual seal includes a primary PTFE seat insert and metal seat.

- In the event that the PTFE insert is destroyed, the secondary metal seat provides an effective shut-off.

Shaft Retention

- Externally retained, double blowout proof stem design as API 609

- External: Shaft is designed with an integral collar and gland follower to prevent blowouts.

Zero Leakage

- Disc-Seat sealing is achieved by evenly loading torque force onto the disc's laminated seal

ISO 5211 Top Mounting

Different End Connections Available: