1-12 of 142 results for "Industry News"

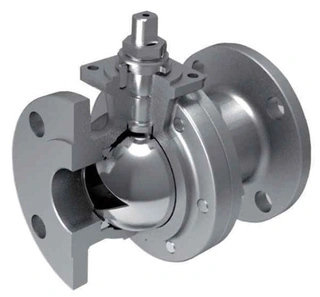

Ball Valve Leakage: Causes, Prevention and Solutions

Industry News

Feb 13, 2026

0

This article provides a comprehensive overview of ball valve leakage, examining its primary causes across internal components, valve bodies, packing, sealing surfaces, and seal ring connections. It outlines practical prevention strategies spanning design, procurement, installation, operation, and maintenance, while also presenting effective troubleshooting and repair methods. By emphasizing proper valve selection, standardized installation, routine inspection, and scientific management, the guide helps engineering professionals minimize leakage risks, enhance sealing reliability, and ensure the safe, stable, and cost-efficient operation of industrial pipeline systems.

Complete Guide to Safety Valve Selection

Industry News

Feb 12, 2026

0

This comprehensive guide to safety valve selection explains key classifications, structural features, operating principles, and parameter determination methods. It outlines how to choose the appropriate valve based on discharge methods, lift height, materials, and working conditions, while also addressing special environments such as high temperature, corrosive media, and high back pressure. With practical recommendations for various applications, the guide helps engineers and procurement professionals make informed decisions to ensure the safe and reliable operation of pressure vessels and pipeline systems.

Guide to Valve Stem Packing Materials

Industry News

Feb 11, 2026

0

This guide provides a comprehensive overview of valve stem packing seals, focusing on their material types, applications, and selection criteria for industrial systems. It covers non-metallic, semi-metallic, and metallic packing, detailing their characteristics, suitability for various media, and performance under extreme conditions. The article also discusses specialized packing solutions for high-temperature, high-pressure, and wear-resistant applications, along with installation and maintenance best practices to ensure optimal sealing and valve longevity.

Guide to V-Port Ball Valves: Structure, Function & Selection

Industry News

Feb 10, 2026

1

V-port ball valves are advanced quarter-turn control valves designed with a V-shaped notch that enables precise flow regulation and strong shearing capability. Combining the shutoff function of traditional ball valves with the throttling performance of control valves, they deliver excellent sealing, high rangeability, and reliable operation across a wide range of conditions. Their robust structure, flexible sealing options, and compatibility with pneumatic or electric actuators make them ideal for demanding industries such as petrochemical, water treatment, pulp and paper, pharmaceuticals, and food processing.

Differences Between Forged Steel Valve and Cast Steel Valve

Industry News

Feb 09, 2026

1

This article provides a comprehensive comparison of forged steel valves and cast steel valves, focusing on their manufacturing processes, material structures, mechanical performance, pressure ratings, and application scenarios. It explains how forging creates denser, stronger valves suitable for high-pressure, high-temperature, and critical service conditions, while casting enables the production of complex shapes and large diameters at a lower cost for medium- to low-pressure systems. By outlining key differences and practical selection principles, the article helps engineers and technical professionals choose the most appropriate valve type to ensure safety, reliability, and economic efficiency in industrial piping systems.

Packed vs. Lubricated Plug Valves: What is the Difference

Industry News

Feb 07, 2026

2

This article provides a comprehensive overview of packed and lubricated plug valves, examining their structural designs, sealing mechanisms, performance characteristics, and typical applications. It highlights the key differences between the two types, including pressure and temperature capabilities, media compatibility, maintenance requirements, and operational advantages. By offering practical comparison and selection guidance, the article helps engineers and industry professionals choose the most suitable plug valve to ensure safe, efficient, and reliable pipeline system performance.

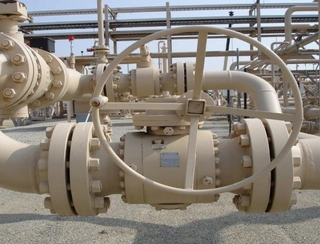

Structural Design of Fully Welded Ball Valves

Industry News

Feb 06, 2026

4

This article provides a comprehensive overview of the structural design of fully welded ball valves, highlighting key elements that influence sealing performance, operational safety, and long-term reliability in pipeline systems. It examines valve body configurations, connection methods, seat sealing technologies, stem sealing structures, ball machining, and support designs, while also addressing fire-safe and anti-static features, DBB functionality, and auxiliary components.

Static & Dynamic Valve Sealing: A Practical Engineering Guide

Industry News

Feb 05, 2026

9

Valve sealing is essential for ensuring the safety, efficiency, and environmental integrity of industrial piping systems. This article provides a comprehensive overview of valve sealing technology, focusing on both static and dynamic sealing methods, their structural designs, material options, and operating principles. It explains how factors such as pressure, temperature, media characteristics, and surface conditions influence sealing performance, while also highlighting common gasket types, packing materials, and advanced solutions like bellows seals and liquid gaskets.

Guide to Troubleshooting of Pneumatic Ball Valves

Industry News

Feb 04, 2026

4

This article provides a comprehensive overview of pneumatic ball valve troubleshooting and maintenance, explaining their working principles, analyzing common failures such as non-operation, sticking, leakage, and vibration, and outlining systematic diagnostic methods. It also presents practical maintenance strategies and key selection considerations to help engineers improve reliability, reduce downtime, and extend valve service life, ultimately ensuring the safe and stable operation of industrial process systems.

Common Safety Valve Failures: Analysis and Maintenance Guide

Industry News

Feb 03, 2026

4

This article provides a comprehensive overview of common safety valve failures, including opening pressure deviations, leakage, chatter, and abnormal reseating. It analyzes the root causes of these issues and outlines practical troubleshooting and maintenance measures. By emphasizing preventive maintenance, correct valve selection, and regular inspection, the guide helps equipment managers and engineers ensure reliable pressure protection, improve operational safety, and support the stable, long-term performance of industrial systems.

Valve Packing Leakage Causes and Effective Countermeasures

Industry News

Feb 02, 2026

12

This article examines the causes of valve packing leakage and outlines practical solutions to prevent and control it. It explains the sealing principle of packing, analyzes common leakage sources such as improper material selection, incorrect installation, valve stem defects, gland issues, and operational errors, and highlights the importance of regular maintenance. The article also presents effective countermeasures, including standardized installation practices, timely replacement, stem repair, stress compensation, and online leak sealing technology.

Brass vs. Bronze Valves: Which Is Better for Your Application?

Industry News

Jan 30, 2026

12

This article provides a comprehensive comparison of brass and bronze valves, highlighting differences in material composition, mechanical properties, corrosion resistance, and application scenarios. Brass, primarily a copper–zinc alloy, offers excellent machinability, moderate strength, and cost-effectiveness, making it ideal for water, gas, and general industrial systems. Bronze, including tin, aluminum, and beryllium variants, delivers superior strength, high corrosion resistance, and stability under extreme conditions, excelling in marine, petrochemical, and specialized industrial environments.

Total 142 Records, 12 records per page