The trunnion mounted ball valve is a high-performance valve designed for high-pressure, large-diameter, and complex fluid control systems. Its unique structure ensures reliable sealing and extended service life, making it ideal for demanding applications. Below are the key design characteristics and working principles of the trunnion mounted ball valve.

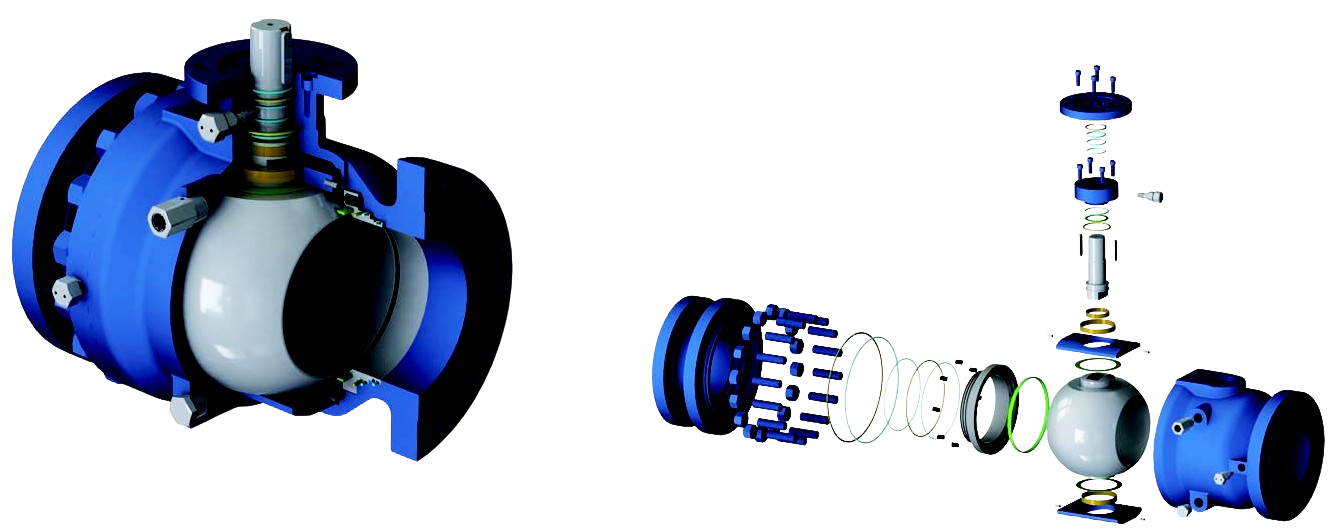

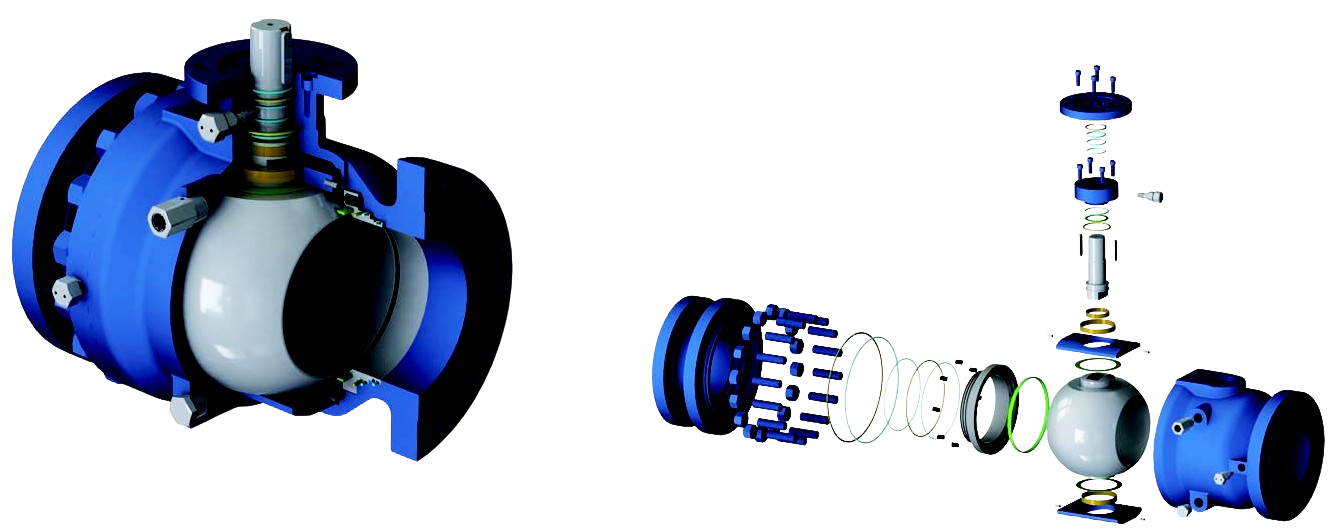

The ball in a trunnion mounted ball valve is supported by trunnions (upper and lower shafts), which hold it in place and prevent movement caused by medium pressure during operation. This fixed position ensures the ball remains unaffected by the fluid flow, reducing the wear on both the ball and the valve seat. The valve seat is typically a floating design, which uses either spring or medium pressure to push the seat into contact with the ball, forming a sealing force. The floating design of the valve seat allows it to move toward the ball under pressure, maintaining a tight seal. This design reduces torque and prevents seat deformation, ensuring stable sealing performance.

3PC Forged Body Side Entry Ball Valve

2PC Casting Body Side Entry Ball Valve

The trunnion mounted ball valve operates by rotating the ball, which has a hole or port that aligns with the pipeline when fully open. Unlike floating ball valves, the force generated by fluid pressure in the trunnion mounted design is transmitted to the bearings, rather than causing the ball to move toward the seat. This design reduces the pressure on the valve seat, enhancing the stability of the seal and prolonging the lifespan of the seats. The valve is equipped with a spring pre-valve seat assembly that effectively achieves upstream sealing, and it features bidirectional sealing capabilities, ensuring effective sealing in both directions without needing to consider flow direction during installation.

3. Trunnion Mounted Ball Valve Body Structure and Installation

Trunnion mounted ball valves come in various body designs, typically two-piece or three-piece, with flanges connected by bolts. The sealing components are often made from enhanced PTFE material embedded in stainless steel rings, ensuring a tight contact between the seat and the ball. The valve's flow aperture is generally consistent with the pipeline's inner diameter, allowing for easy cleaning and maintenance of the pipeline. This design ensures the valve operates efficiently even in complex environments.

The trunnion mounted ball valve is widely used in high-pressure, large-diameter pipelines due to its high performance and reliability. It includes several key features that make it effective in complex environments.

Spring-Preloaded Floating Valve Seat Design: This feature ensures effective sealing of upstream and downstream seats when the valve is fully open or closed. It also allows the retained medium in the valve cavity to automatically release pressure if abnormal pressure increases due to temperature rises, eliminating the need for a separate safety valve.

Fire Safety Features: The valve meets API 607 and API 6FA fire safety standards, providing additional protection under extreme conditions like fires. This ensures the valve can continue to operate safely even under hazardous circumstances.

The sealing system in the trunnion mounted ball valve is highly advanced. To prevent sealing failure caused by foreign substances or fire, the valve is equipped with a grease injection valve that allows grease to be injected into the sealing area to address leakage issues quickly. The valve also features a double sealing system, including an O-ring at the packing gland to enhance stem sealing. In extreme environments, such as fires, the addition of graphite packing and the grease injection system reduces stem leakage and further enhances the valve's durability.

2. Operation and Maintenance

The operation of the trunnion mounted ball valve is made smoother by sliding and thrust bearings on the valve stem, ensuring effortless operation even without sealing grease. The valve can be selected in full-bore or reduced-bore configurations. Full-bore valves have flow apertures that match the pipeline's inner diameter, making it easier to clean and maintain pipelines for long-term operation.

Additionally, the valve stem can be extended to meet specific application needs, which is especially important for underground installations. In systems like urban gas pipelines that require underground installation, the extended valve stem offers a flexible solution.

The trunnion mounted ball valve is suitable for a wide range of fluid mediums, including steam, gas, oil, and various acidic or alkaline media. Its resistance to high pressure, corrosion, and fire makes it highly effective in complex industrial environments. Commonly used in high-pressure, large-diameter pipelines in industries such as petroleum, chemical, power generation, and natural gas, it can handle extreme working conditions while ensuring safe and precise fluid control.