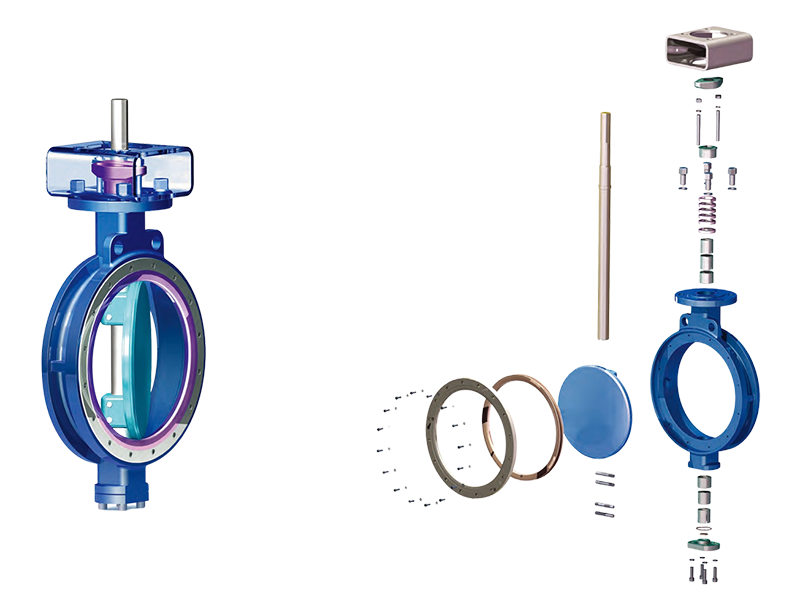

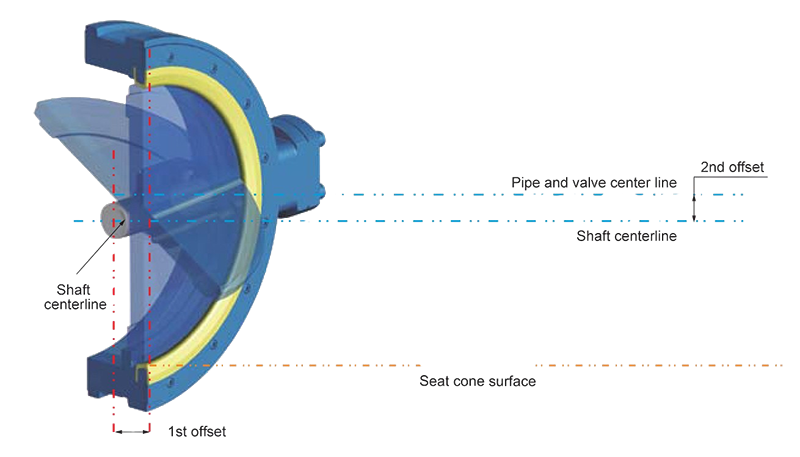

High performance butterfly valve, or double eccentric butterfly valve, is widely used in water treatment, power plants, steel mills, chemical industries, and environmental engineering, particularly for flow regulation and shutoff in pipelines. Compared to concentric butterfly valves, they offer higher pressure resistance, longer lifespan, and greater stability. In large diameters, they are lighter and more cost-effective, but for sizes below DN200, increased flow resistance limits practicality. The double eccentric design offsets the valve stem from the disc and body centers, allowing the disc to quickly disengage from the seat. This reduces wear, lowers torque, extends seat life, and enables the use of metal seats for high-temperature applications.

High Performance Butterfly Valve Product List

Total 17 Records, 16 records per page