13-24 of 142 results for "Industry News"

Control Valve Leakage Classes Explained

Industry News

Jan 29, 2026

18

This article explains control valve leakage classes as defined by ANSI standards, clarifying common misconceptions and highlighting how valve type, pressure differential, and actuator capability influence shutoff performance. It provides practical guidance for selecting appropriate leakage classes based on real operating conditions, helping engineers balance safety, reliability, and cost in industrial flow control applications.

Why Extended Bonnet Designs Used in Cryogenic Valves

Industry News

Jan 28, 2026

11

This article explains why extended bonnet designs are essential for cryogenic valves used in LNG and other ultra-low-temperature applications. By creating a controlled temperature gradient, the extended bonnet protects operators from extreme cold, maintains packing elasticity and sealing integrity, and facilitates insulation and maintenance. The discussion covers key engineering principles, international standards, condensation control, pressure relief, anti-static and fire-safe features, as well as material and sealing considerations, highlighting how this seemingly simple structural feature plays a critical role in ensuring the safety, reliability, and long-term performance of cryogenic valve systems.

How to Select the Right Strainer for Pipeline Protection

Industry News

Jan 27, 2026

8

This article provides a comprehensive yet practical guide to strainer selection for industrial pipeline systems. It explains the working principles of strainers, compares common types such as Y strainers, basket strainers, and T strainers, and outlines key selection criteria including size, pressure rating, filtration accuracy, material, flow rate, temperature, and maintenance requirements. Through typical application examples in steam, cooling water, oil, and fuel systems, the article demonstrates how proper strainer selection protects downstream equipment, improves system reliability, reduces operating costs, and ensures safe and efficient process operation.

Single Disc Gate Valve vs. Double Disc Gate Valve

Industry News

Jan 26, 2026

11

This article provides an in-depth comparison of single disc and double disc gate valves, focusing on their sealing principles, structural characteristics, performance advantages, and practical application scenarios. It examines how factors such as machining accuracy, sealing materials, pressure, and temperature influence valve performance, while highlighting the strengths and limitations of each design. Elastic wedge gate valves are also discussed as an optimized alternative to traditional single disc valves.

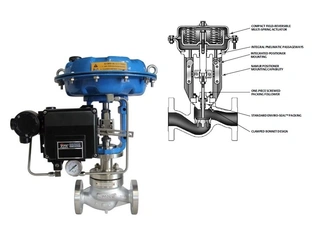

What is Diaphragm Type Pneumatic Control Valve

Industry News

Jan 24, 2026

7

Diaphragm type pneumatic control valves are essential for precise regulation of flow, pressure, and temperature in industrial processes. This article explores their structure, working principle, selection criteria, installation guidelines, maintenance practices, and troubleshooting methods. It also highlights practical applications in chemical, petrochemical, and power industries, demonstrating how proper valve selection, installation, and upkeep ensure efficient, safe, and stable operation while optimizing product quality and energy efficiency.

Optimizing Metal-Seated Ball Valves for Extreme Conditions

Industry News

Jan 23, 2026

4

This article examines the performance challenges faced by metal-seated ball valves operating under harsh conditions such as high temperatures, strong corrosion, and particle-laden media. It analyzes the fundamental differences between metal-seated and soft-seated designs, identifies key failure mechanisms including sealing surface damage, excessive operating torque, and corrosion, and discusses their impact on valve reliability. The paper further presents practical optimization strategies, covering sealing structure design, spring and disc spring applications, advanced hard-facing coatings, and supporting maintenance practices.

What Is a Thermodynamic Steam Trap

Industry News

Jan 22, 2026

7

This article provides a comprehensive overview of thermodynamic steam traps, explaining their basic structure, operating principle, common types, advantages, limitations, and typical applications in industrial steam systems. It highlights how these traps efficiently discharge condensate while preventing steam loss through a simple, robust disc-based design that performs reliably under high-pressure and high-temperature conditions.

Bronze Ball Valves: Structure, Material Properties & Selection

Industry News

Jan 21, 2026

8

This article provides a comprehensive overview of bronze ball valves, covering their operating principles, material characteristics, selection considerations, application areas, and maintenance practices. Emphasis is placed on the corrosion resistance, strength, durability, and cost-effectiveness of bronze as a valve material, along with guidance on choosing suitable pressure ratings, connections, bore types, actuation methods, and sealing options. The article highlights the technical advantages and practical value of bronze ball valves in marine, chemical, water treatment, fire protection, and civil piping systems.

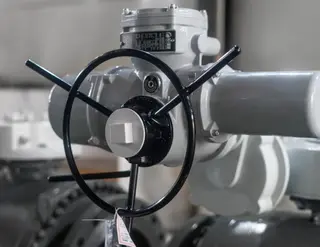

Electric Ball Valves: On–Off vs. Modulating Types

Industry News

Jan 20, 2026

13

This article provides a comprehensive overview of electric ball valves, focusing on the differences between on–off and modulating types in terms of structure, operating principles, control methods, and applications. It explains how on–off electric ball valves are used for simple media isolation, while modulating electric ball valves enable precise control of flow, pressure, and temperature through analog signals.

Pinch Valves: High-Performance Valves for Challenging Media

Industry News

Jan 19, 2026

4

This article provides a comprehensive overview of pinch valves as efficient and durable industrial flow control solutions. It explains their structure and working principles, highlights key advantages such as leak-free sealing, low maintenance cost, smooth flow, and flexible actuation options, and examines their wide application in chemical processing, pulp and paper, food, water treatment, and mineral processing industries.

Guide to Soft Seal Butterfly Valves

Industry News

Jan 16, 2026

7

Soft seal butterfly valves use soft non-metallic seals to deliver reliable zero-leakage performance, low operating torque, and compact design. Commonly applied in water treatment, ventilation, and chemical systems, this article outlines their structure, types, materials, connections, applications, and maintenance to support proper selection and reliable operation.

Installation and Maintenance of Fully Welded Ball Valves

Industry News

Jan 15, 2026

8

This section focuses on the detailed installation procedures of fully welded ball valves, outlining clear workflows and key operational points to guide proper installation. By explaining each step in a practical and structured manner, it helps ensure reliable sealing, stable performance, and long-term operational efficiency in real-world applications.

Total 142 Records, 12 records per page