Lift plug valves are essential components in industrial fluid control systems, widely used in industries such as oil and gas, chemical, power, metallurgy, and environmental protection. These valves combine lifting and rotating actions to provide efficient fluid regulation, making them suitable for a variety of complex and demanding operational environments. This article examines the structure, functionality, and advantages of lift plug valves, with a focus on their sealing performance, double-seal design, pressure balancing, and fire-safe features. The discussion also highlights the benefits of metal hard-seal lift plug valves, such as their high temperature and pressure resistance, as well as ease of maintenance. Ultimately, lift plug valves play a crucial role in ensuring safe and reliable fluid control in modern industrial applications.

The lift plug valve is a critical pipeline control valve widely used in various industrial applications that require precise fluid regulation, opening, closing, and sealing. Its unique structural design and efficient sealing performance make it indispensable in industries such as oil and gas, chemical, power, metallurgy, and environmental protection. By combining the lifting and rotating actions of the plug, the lift plug valve provides efficient fluid control, making it suitable for a wide range of complex working conditions. This article delves into the structural features, functional advantages, and application areas of lift plug valves.

The working principle of lift plug valves relies on the combined lifting and rotating operation of the plug body. This design ensures efficient sealing and fluid control during the opening and closing processes.

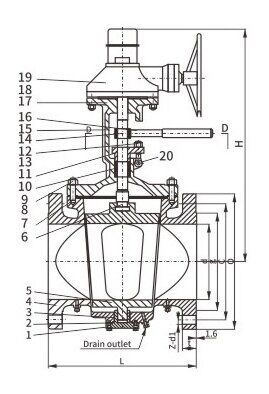

The plug body of a lift plug valve is typically composed of three plates, forming a cylindrical plug. Rubber or metal sealing surfaces are embedded on the side plates, while the middle part consists of a cylindrical wedge. The overall design of the plug body ensures durability and sealing performance, enabling the valve to withstand high pressure and high-temperature environments.

Opening Process: When the valve opens, the transmission mechanism drives the plug to rise, causing the side plates to retract inward. This action disengages the combined plug body from the valve sealing surface. The plug then rotates 90°, placing the valve in a fully open state, allowing fluid to flow smoothly.

Closing Process: During closure, the transmission mechanism rotates the combined plug body 90° to the closed position and then pushes the plug downward. The side plates come into contact with the valve body's bottom and stop moving. The wedge's inclined surface pushes the side plates toward the inlet and outlet ends, ensuring the sealing surfaces come into contact and compress, achieving reliable sealing.

Double-seal lift plug valves incorporate both soft and metal seals, enhancing sealing performance and adaptability to more complex working conditions.

The double-seal structure includes soft and metal seals, effectively preventing leakage and providing higher safety. Soft seals are primarily used in low-pressure conditions, while metal seals ensure sealing in high-temperature and high-pressure environments. The combination of the two significantly improves the valve's sealing performance.

Double-seal lift plug valves feature a double block and bleed function, effectively preventing medium leakage when the valve is closed. Additionally, they can discharge any accumulated medium within the system, avoiding abnormal pressure buildup. This design greatly enhances safety in hazardous and extreme conditions.

The valve is equipped with a pressure balancing device that prevents system overpressure. By balancing the pressure difference between the valve's interior and exterior, the device reduces resistance during operation, ensuring smoother valve movement.

The metal sealing surfaces in the double-seal design come into contact during valve operation, providing fire-safe functionality. In high-temperature or fire scenarios, the metal seals maintain effective sealing, ensuring valve safety.

Unlike other valve types, double-seal lift plug valves are designed for easy maintenance. Users can replace the side plates by simply removing the bottom end cover, eliminating the need to disassemble the entire valve body. This design reduces maintenance costs and downtime.

Metal hard-seal lift plug valves use metal sealing surfaces, offering superior resistance to high temperatures, corrosion, and pressure. They are particularly suitable for fluid control in high-temperature, high-pressure, and harsh environments, with several notable advantages.

Metal hard-seal lift plug valves employ hard metal sealing surfaces, maintaining excellent sealing performance in high-temperature, high-pressure, or corrosive environments. The sealing surfaces are resistant to medium erosion, extending the valve's service life.

Unlike traditional plug valves, metal hard-seal lift plug valves feature a circular channel design that matches the pipeline cross-section, minimizing fluid resistance. This design makes valve operation smoother and reduces energy loss during fluid flow.

Metal hard-seal lift plug valves can withstand higher temperatures and pressures, making them ideal for industries such as petrochemicals, power, and metallurgy. The metal sealing surfaces ensure stable operation under extreme conditions, maintaining fluid flow stability and system safety.

The raised sealing surface design of metal hard-seal lift plug valves facilitates cleaning and prevents the accumulation of crystalline media or solid particles. This design simplifies daily maintenance, particularly in chemical installations.

The sealing surfaces of these valves can seal in both directions, making them suitable for bidirectional fluid control and expanding their application range.

Lift plug valves have gained widespread application across various industries due to their unique structural design and powerful functional advantages. Whether it is the high safety and double block and bleed function of double-seal lift plug valves or the high-temperature and high-pressure resistance of metal hard-seal lift plug valves, these valves have become indispensable in modern industrial fluid control. As industrial demands continue to grow, lift plug valves will remain essential in fluid regulation and control, playing an irreplaceable role.