This article compares R (sealed) and G (unsealed) pipe threads, focusing on their design, sealing mechanisms, applications, and key differences. R threads, with a conical taper and built-in sealing features, are ideal for high-pressure and vibration-sensitive systems, utilizing materials like raw tape or sealants for a leak-proof seal. In contrast, G threads are cylindrical and depend on external sealing methods, such as gaskets, suitable for low-pressure applications. The article also highlights best practices for installation and sealing, regional sealing techniques, and the use of anaerobic adhesives to enhance sealing performance, helping to choose the appropriate thread type for specific applications.

Pipe threads are essential components in ensuring secure connections between pipes and pipe fittings in a variety of industrial applications. They play a crucial role in preventing leaks, maintaining system integrity, and facilitating easy installation and maintenance. In this article, we'll focus on R (sealed) and G (unsealed) pipe threads, comparing their key features, applications, sealing mechanisms, and advantages.

R threads are designed for applications where a sealed connection is essential. They are widely used in plumbing and industrial systems where preventing leaks under pressure is critical.

R threads include the following variations:

RP: Cylindrical internal thread.

R1: Conical external thread matched with cylindrical internal thread.

RC: Conical internal thread.

R2: Conical external thread matched with conical internal thread.

Each type is designed to meet specific requirements based on the pressure, flow, and system conditions.

Profile Angle: The profile angle of R threads is 55°.

Thread Geometry: The threads are designed with an arc-shaped top and bottom.

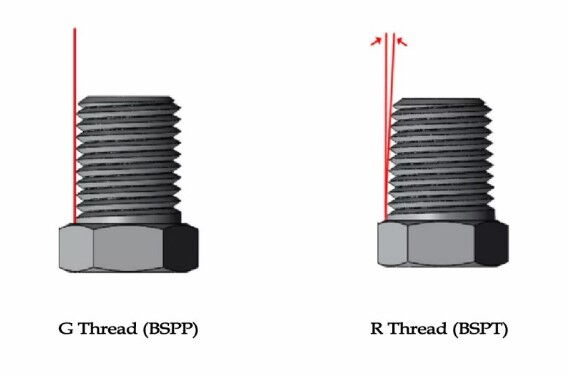

Taper: R threads include conical threads with a 1:16 taper ratio, which is crucial for achieving the sealing effect upon tightening.

R threads are specifically designed to create a seal upon tightening. The sealing capability comes from the interaction between the conical surfaces of the internal and external threads. The seal is enhanced by raw material belts or sealant applied during installation, ensuring a leak-proof connection.

Sealing Methods: Common sealing methods for R threads include:

Raw material tape: Often used in combination with the conical threads to ensure a tight seal.

Sealant application: Some systems use anaerobic sealants, which harden in the absence of air, to reinforce the seal.

R threads are commonly used in:

High-pressure systems: For systems like industrial gas pipelines, high-pressure steam lines, and water systems under pressure.

Impact-prone applications: Where vibrations or sudden pressure surges may occur, such as in heavy machinery or automotive components.

Water and gas pipes: Especially for static load applications where leakage prevention is critical.

In contrast to R threads, G threads are not designed for sealing and are primarily used for mechanical fastening. They are used in low-pressure systems or where external sealing mechanisms are used to prevent leaks.

Cylindrical Pipe Threads: G threads are typically cylindrical with a consistent diameter along their length, meaning they do not taper like R threads.

Profile Angle: The profile angle of G threads is also 55°, similar to R threads.

Thread Geometry: The threads are arc-shaped, but they are designed for connection purposes rather than sealing.

Taper: G threads have no taper, meaning they are cylindrical, in contrast to the conical R threads.

Since G threads are unsealed, they rely on additional sealing components, such as gaskets or sealing rings, to prevent leaks. These external sealing components are crucial for ensuring a leak-proof connection when G threads are used in applications with low-pressure requirements.

Sealing Methods: For G threads, the most common sealing method involves the use of a combined gasket to create a tight seal between the connected components.

G threads are typically used in applications where the sealing is not required at the thread level but is achieved via external sealing components. These include:

Low-pressure applications: Such as water or air systems where the internal pressure is low and controlled.

Static load systems: Where there is no risk of pressure surges or vibrations that could cause leaks.

Simple connections: In systems where a tight seal is not essential, and the threads are used mainly for mechanical fastening.

|

Feature |

R Threads (Sealed) |

G Threads (Unsealed) |

|

Thread Type |

Tapered (Conical) |

Cylindrical |

|

Profile Angle |

55° |

55° |

|

Taper |

1:16 |

None |

|

Seal Type |

Built-in seal with raw material tape or sealant |

External seal (gaskets or sealing rings) |

|

Applications |

High-pressure systems, water/gas pipelines |

Low-pressure systems, static load applications |

|

Sealing Performance |

Sealed after tightening |

Requires external sealing components |

The sealing mechanism is a major differentiator between R and G threads. R threads are designed to provide an inherent seal upon tightening, especially for high-pressure and impact-resistant applications. Conversely, G threads rely on external sealing components like gaskets, which need to be correctly installed to ensure a leak-proof connection.

R Thread Sealing: The sealing performance of R threads is achieved through the combination of the tapered thread geometry and the application of sealing materials (e.g., raw material belts, sealant).

G Thread Sealing: For G threads, sealing is achieved by using external components like gaskets. These seals must be properly installed to prevent leaks.

Regardless of the type of pipe thread used, ensuring a leak-proof connection requires attention to detail during installation:

R Threads: Ensure the correct application of sealing materials, like raw material tape or anaerobic sealants, and verify that the threads are properly tightened to create an effective seal.

G Threads: Properly install the sealing gasket and ensure that it matches the pipe material and system conditions. Ensure that the joint surfaces are clean and smooth to achieve a reliable seal.

Different regions use different sealing techniques, which can impact performance.

Japan: Taper pipe threads (like R threads) are commonly sealed using raw material tape along with sealants. This method is effective when applied with high precision and care.

Europe and the US: Taper pipe threads in these regions often use gaskets for sealing. The gasket material must be compatible with the pressure and temperature conditions of the system.

To enhance the sealing performance of pipe threads, anaerobic adhesives (e.g., H-330) are commonly used. These one-component adhesives harden in the absence of air and are particularly useful in machinery and pipe fittings where additional sealing is required.

Anaerobic Adhesive Properties: These adhesives work by polymerizing in oxygen-deprived conditions and are designed to both bond and seal. They are widely used in industrial and automotive applications for securing and sealing pipe threads.

Understanding the differences between R (sealed) and G (unsealed) pipe threads is crucial for selecting the appropriate type for your application. R threads offer an integrated sealing solution for high-pressure systems, while G threads are used in low-pressure connections with external sealing components. By carefully considering the thread type, sealing method, and application requirements, you can ensure reliable, leak-free connections in your piping systems.