25-36 of 142 results for "Industry News"

Guide to Industrial Valve Pressure Testing

Industry News

Jan 14, 2026

7

This article provides a comprehensive overview of industrial valve pressure testing, explaining its importance in ensuring valve safety, sealing integrity, and reliable performance. It details key test types, including shell, seat, and backseat tests, along with applicable international standards, test pressures, media selection, and practical operational considerations. By outlining testing methods for different valve types and highlighting common precautions, the article serves as a practical reference for manufacturers and users seeking to improve valve quality, compliance, and operational safety.

What is Double Eccentric Segmented Ball Valve

Industry News

Jan 13, 2026

7

The Double Eccentric Segmented Ball Valve is a high-performance industrial valve engineered for severe and complex operating conditions. By integrating the advantages of ball valves, V-port valves, and orbit ball valves, and utilizing a unique double-eccentric metal-to-metal sealing design, it achieves low operating torque, minimal wear, and reliable zero-leakage performance. Its ability to withstand high temperature, high pressure, abrasion, corrosion, and particulate-laden media, combined with easy operation and convenient maintenance, makes it an ideal solution for demanding pipeline control applications across industries.

How to Choose the Right Control Valve

Industry News

Jan 12, 2026

17

This article provides a comprehensive guide to control valve selection, explaining how to choose the most suitable valve based on process requirements and operating conditions. It covers key factors such as valve performance, sealing and shutoff capability, anti-clogging and corrosion resistance, pressure and temperature limits, flow characteristics, flow direction, and material selection.

Orbit Plug Valves: Structure, Performance & Best Practices

Industry News

Jan 10, 2026

6

Orbit plug valves are high-performance industrial valves known for their simple structure, excellent sealing, low flow resistance, and long service life. Widely used across petroleum, chemical, metallurgical, and power industries, they provide reliable fluid control under demanding conditions. With flexible operation, easy maintenance, and durable materials, orbit plug valves ensure safe, efficient, and stable pipeline performance, making them a key solution for modern industrial fluid management.

Ball Valve Trim Types: Selection and Application Guide

Industry News

Jan 09, 2026

10

This guide provides a comprehensive overview of ball valve trim types, including floating, trunnion-mounted, V-port, eccentric, and orbit designs. It explains their structures, performance characteristics, advantages, limitations, and typical applications, offering practical guidance for selecting the most suitable trim based on operating conditions, media properties, and system requirements to ensure optimal valve performance, reliability, and cost-effectiveness in industrial piping systems.

A Complete Guide to Mechanical Steam Traps

Industry News

Jan 08, 2026

9

Mechanical steam traps are essential components in industrial steam systems, designed to efficiently discharge condensate while preventing steam loss. Operating on the principle of density difference between steam and condensate, these traps, including free float, half-float, lever float, inverted bucket, and combined superheated types, ensure optimal heat transfer, energy savings, and reliable operation across various pressures and loads.

An Introduction to Metal-Seated Butterfly Valves

Industry News

Jan 07, 2026

4

This article outlines the key features and advantages of metal-seated butterfly valves, focusing on their triple-offset design, superior sealing performance, flexible operation, and long service life. It highlights their suitability for high-temperature, high-pressure, and corrosive conditions, along with their broad applications in industries such as chemical processing, oil and gas, power generation, metallurgy, and papermaking. The article also emphasizes proper installation and maintenance as essential factors in ensuring reliable, long-term valve performance.

A Complete Guide to Diaphragm Valve Maintenance

Industry News

Jan 06, 2026

15

This section provides a practical overview of the most common diaphragm valve failures encountered during operation, including diaphragm rupture, operational malfunction, stiff handwheel movement, inability to open or close automatically, and leakage at the valve body–bonnet connection. It explains the root causes of each issue, such as material aging, improper operation, mechanical wear, insufficient air pressure, and loose fasteners, and outlines clear, effective corrective measures.

What is Dual Plate Wafer Check Valve

Industry News

Jan 05, 2026

13

The dual plate wafer check valve is a vital component in industrial and civil piping systems, ensuring one-way fluid flow, preventing backflow, and protecting equipment. Combining rapid closure, minimal pressure drop, and versatile installation, it excels in high-pressure, high-velocity pipelines across chemical, power, oil and gas, municipal water, wastewater, and fire protection applications.

Wafer Butterfly Valves vs. Flanged Butterfly Valves

Industry News

Dec 29, 2025

12

Butterfly valves are essential components in piping systems, with wafer and flanged types being the most common. This article explores their key features, advantages, sealing performance, installation methods, cost considerations, and typical applications. Wafer valves offer a compact, lightweight, and cost-effective solution for medium-to-low pressure systems, while flanged valves provide superior sealing, high pressure resistance, and vibration tolerance for demanding industrial applications. By understanding their differences and evaluating pressure, temperature, space, cost, and application requirements, engineers and system designers can select the most suitable valve to ensure safe, efficient, and reliable system operation.

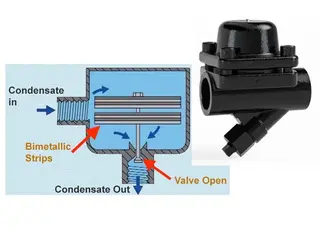

What is Bimetallic Steam Trap?

Industry News

Dec 26, 2025

20

Bimetallic steam traps are crucial for efficient steam system operation, automatically discharging condensate while preventing steam loss. They use a bimetallic element that deforms with temperature changes to control valve movement. These traps are simple, durable, and energy-efficient, suitable for applications like steam tracing and medium-low pressure systems. However, they have limitations such as fixed discharge temperatures and potential element fatigue. Proper selection and maintenance are key to maximizing their performance and lifespan.

Key Factors in Cryogenic Ball Valve Material Selection

Industry News

Dec 25, 2025

13

In industrial fields, cryogenic ball valves, as an important control device, are widely used in liquefied natural gas, petrochemicals, refrigeration, and other industries. Their core function is to precisely control the flow of fluids under low-temperature conditions. However, low-temperature...

Total 142 Records, 12 records per page