Ball valves and butterfly valves, as two common types of valves in industrial piping systems, play significant roles in numerous industrial applications due to their unique structural and performance characteristics. Ball valves are favored for their excellent sealing performance and high pressure-bearing capacity, while butterfly valves are widely used for their rapid opening and closing speed and relatively simple structure. There are notable differences between them in terms of design, operational convenience, sealing performance, and application scenarios, which give them respective advantages in different industrial environments. A thorough understanding of the characteristics and differences of ball valves and butterfly valves is crucial for selecting the appropriate valve to meet specific industrial needs.

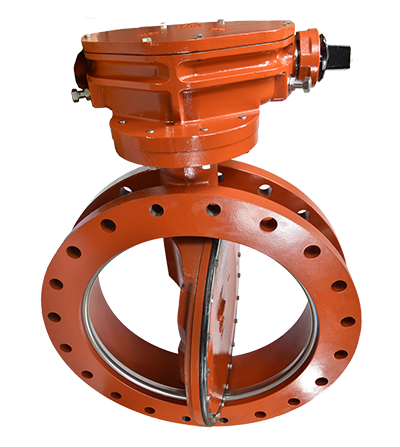

Butterfly Valve: The construction of a butterfly valve is relatively simple and clear, mainly consisting of four parts: the valve body, valve seat, valve plate, and valve stem. The valve plate is the core component of the butterfly valve, installed in the diameter direction of the pipeline. Within the cylindrical passage of the valve body, the disc-shaped butterfly plate rotates around the axis, with a rotation angle ranging from 0° to 90°. When the butterfly plate rotates to 90°, the valve is fully open, allowing fluid to flow smoothly through the pipeline. When the butterfly plate rotates to 0°, the valve is completely closed, blocking the fluid flow. This rotating opening and closing method of the butterfly valve makes its operation very simple and quick, requiring only a 90° rotation of the valve stem to open or close the valve.

Ball Valve: The construction of a ball valve is slightly more complex. It consists of the valve body, valve core (a spherical shape), and valve stem. The valve core is the key component of the ball valve. It is a sphere that rotates around the centerline of the valve body to achieve opening and closing. The position of the valve core is inside the valve body, and only a part of it can be seen with the naked eye, which gives the ball valve relatively better sealing performance compared to the butterfly valve. During the opening and closing process of the ball valve, the sphere operates under the clamping force of the two end valve seats. It can close tightly with a 90° rotation and a small amount of rotational torque. The valve body of a ball valve can be either integral or assembled, and this structural design makes the ball valve highly flexible in different application scenarios.

The comparison of performance characteristics of ball valves and butterfly valves not only helps us gain a more comprehensive understanding of these two types of valves but also provides important reference for selection in practical applications. Therefore, we will conduct a detailed comparative analysis of ball valves and butterfly valves from several aspects, including sealing performance, pressure-bearing capacity, opening and closing speed and torque, and flow regulation capability.

The sealing performance of butterfly valves is relatively weak. Their sealing relies on rubber as an intermediary. Although this sealing method is low in cost, it is far inferior to the metal hard sealing of ball valves and gate valves. The sealing of butterfly valves mainly depends on rubber seals. After long-term use, rubber seals are prone to aging and wear, resulting in a decline in sealing performance. However, butterfly valves are also divided into soft-seal and hard-seal types. Soft-seal butterfly valves have a maximum temperature of below 150 degrees and a pressure of below 16 kilograms. Hard-seal butterfly valves can be single-eccentric, double-eccentric, or triple-eccentric. Among them, triple-eccentric butterfly valves have relatively better sealing performance, but the pressure can only reach below 64 kilograms.

The sealing performance of ball valves is much better. It relies on the long-term compression of the valve seat on the ball surface to achieve sealing. The sealing of ball valves usually uses flexible materials that can achieve complete sealing under higher pressure and temperature. Soft-seal ball valves have a maximum temperature of below 280 degrees and a pressure of below 64 kilograms. Hard-seal ball valves can reach a maximum temperature of below 425 degrees and a pressure of below 100 kilograms. However, the sealing of ball valves is not perfect. Due to the long-term compression of the valve seat on the ball surface, wear is relatively faster, especially in high-temperature and high-pressure environments. The performance of the sealing material will be affected to some extent, making it difficult to maintain good sealing effects for a long time.

The pressure-bearing capacity of butterfly valves is relatively weak, with a maximum pressure of only 64 kilograms. The structure of butterfly valves is relatively simple, mainly relying on rubber seals to achieve sealing. This structure is prone to deformation and leakage when subjected to higher pressure. The valve plate and valve seat of the butterfly valve will undergo certain elastic deformation when subjected to pressure. When the pressure exceeds a certain limit, this deformation will lead to sealing failure, thereby affecting the normal operation of the valve.

The pressure-bearing capacity of ball valves is much stronger, with a maximum pressure of up to 100 kilograms. The structure of ball valves is relatively complex. The valve core is a sphere, and the sphere and valve seat achieve sealing through close fitting. When subjected to pressure, the sphere and valve seat can withstand higher pressure without easy deformation or leakage. The valve body of a ball valve is usually made of high-strength materials, which can effectively withstand the pressure of high-pressure fluid and ensure the safe operation of the valve.

Butterfly valves have a fast opening and closing speed, requiring only a 90° rotation to open or close the valve, making the operation very simple and quick. The opening and closing torque of butterfly valves is relatively large because they need to overcome the deformation of rubber to achieve opening and closing. During the opening and closing process of the butterfly valve, the valve plate needs to overcome the elastic resistance of the rubber seal, resulting in a relatively large opening and closing torque. However, despite the relatively large opening and closing torque of butterfly valves, they are still widely used in various industrial applications due to their simple operation.

Ball valves can also open and close quickly. They only need a 90-degree rotation and a small amount of rotational torque to close tightly. The opening and closing torque of ball valves is relatively small because they operate under the clamping force of the two end valve seats during the opening and closing process. This clamping force makes the torque required for opening and closing relatively small. However, as the diameter of the ball valve increases, the contact area of the sealing surface also increases exponentially. Therefore, the opening and closing torque of large-diameter ball valves can be very large, which to some extent limits the application of ball valves in large-diameter pipelines.

Both butterfly valves and gate valves can regulate flow through their opening degree, and butterfly valves have a larger adjustable range. During the rotation of the butterfly valve's valve plate, the flow area of the fluid can be changed to achieve flow regulation. This flow regulation method of butterfly valves makes them widely used in situations where precise flow control is required. The structural principle of butterfly valves is particularly suitable for making large-diameter valves. Large-diameter butterfly valves can regulate large flows by adjusting the opening angle of the valve plate, meeting the needs of different industrial applications.

Ball valves are not convenient for regulating flow through their opening degree. The main function of ball valves is to cut off, distribute, and change the flow direction of the medium, rather than to precisely control the flow. The valve core of a ball valve is a sphere, and although the flow area of the fluid can also be changed during the rotation of the sphere, the shape and structural characteristics of the sphere make the precision of flow regulation relatively low for ball valves. Therefore, ball valves are generally not used in situations where precise flow control is required.

Butterfly Valve Applications: Butterfly valves have a simple structure and low cost, making them suitable for low-pressure applications where sealing performance is not a high priority. They are widely used in general industrial fields such as oil, gas, chemicals, and water treatment, especially in large-diameter pipeline systems. For example, in urban water supply systems, butterfly valves are often used to control the flow of water. Their large diameter and low cost make them an ideal valve choice. Additionally, butterfly valves can be applied in the cooling water systems of thermal power stations to regulate the flow of cooling water by adjusting the opening angle of the valve plate, meeting the stations' requirements for cooling water flow regulation.

Ball Valve Applications: Ball valves offer excellent sealing performance and high pressure-bearing capacity, making them suitable for applications where these characteristics are highly demanded. They are typically used for liquids and gases without particulate impurities, resulting in minimal fluid pressure loss. Ball valves are appropriate for general working media such as water, solvents, acids, and natural gas, as well as for harsh working conditions involving media like oxygen, hydrogen peroxide, methane, and ethylene. For instance, in oil and natural gas transmission pipelines, ball valves are commonly used to cut off and control the flow of natural gas. Their superior sealing performance and pressure-bearing capacity ensure the safe and stable transportation of natural gas. Moreover, ball valves are extensively used in chemical industry pipelines for conveying corrosive media, where their corrosion-resistant properties help maintain the normal operation of the pipeline system.

When selecting between ball valves and butterfly valves, a comprehensive consideration of various factors is necessary, including the pressure, temperature, flow regulation requirements, sealing requirements, and cost budget of the piping system. The following are some selection suggestions.

If the working pressure of the piping system is relatively low, generally below 64 kilograms, a butterfly valve can be chosen. Butterfly valves have a simple structure and low cost, which can meet the requirements of low-pressure piping systems. If the working pressure of the piping system is higher, exceeding 64 kilograms, it is recommended to select a ball valve. Ball valves have a strong pressure-bearing capacity, with a maximum pressure of up to 100 kilograms, which can effectively withstand the pressure of high-pressure fluids and ensure the safe operation of the piping system.

The temperature range of butterfly valves is relatively narrow. Soft-seal butterfly valves have a maximum temperature of below 150 degrees, and hard-seal butterfly valves have a pressure of below 64 kilograms. If the working temperature of the piping system exceeds 150 degrees, a ball valve is recommended. Ball valves have a wider temperature range. Soft-seal ball valves have a maximum temperature of below 280 degrees, and hard-seal ball valves can reach a maximum temperature of below 425 degrees, which can meet the requirements of high-temperature piping systems.

If the piping system requires precise flow control, a butterfly valve is recommended. Butterfly valves can achieve precise flow control by adjusting the opening angle of the valve plate, meeting the flow regulation requirements of different industrial applications. If the piping system has low flow regulation requirements and mainly needs to cut off and control the flow direction of the fluid, a ball valve can be chosen. Ball valves have good sealing performance and strong pressure-bearing capacity, which can effectively cut off the fluid flow and ensure the normal operation of the piping system.

Butterfly valves have a simple structure and low cost. If the budget for the piping system is limited, a butterfly valve can be selected. Butterfly valves are inexpensive and can meet the requirements of general industrial applications. Ball valves have a relatively complex structure and higher cost. If the budget for the piping system is sufficient and higher requirements for sealing performance and pressure-bearing capacity are needed, a ball valve can be chosen. Ball valves have superior performance and can ensure the long-term stable operation of the piping system. Although they are more expensive, they offer higher cost-effectiveness in the long run.

Ball valves and butterfly valves, as important valve types in industrial piping, each have unique structures, performance characteristics, and application scenarios. Butterfly valves are simple in structure, low in cost, and fast in opening and closing, making them suitable for low-pressure applications where sealing performance is not a high priority. Ball valves have excellent sealing performance and strong pressure-bearing capacity, making them suitable for applications with high requirements for sealing and pressure-bearing. When selecting between ball valves and butterfly valves, a comprehensive consideration of factors such as the pressure, temperature, flow regulation requirements, sealing requirements, and cost budget of the piping system is necessary to choose the most suitable valve type to ensure the safe, stable, and efficient operation of the piping system.