Key Specifications / Features

- Model No.: KV-20250124-OPV-02

- Hits: 30

- Categories: Other Plug Valves

- Tags: Dual Expanding Plug Valve, ASTM A216 WCB Plug Valve, 16 Inch Plug Valve

Detail Information

Product Name: Dual Expanding Seal Plug Valve

Design Standard: API 6D, API 599

Body Material: ASTM A216 WCB

Size: 16 Inch, DN400

Pressure: Class 900 LB, PN150

End Connection: RTJ Flanged

Operation: Handwheel

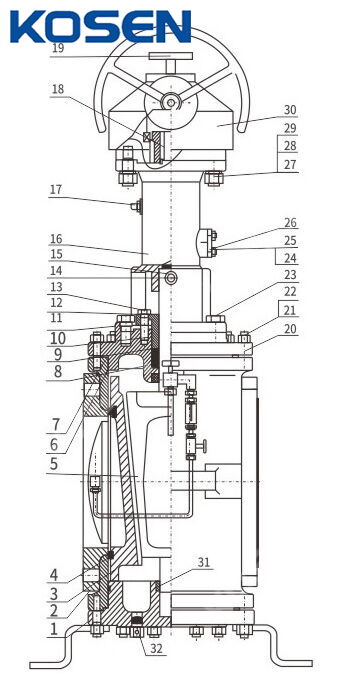

When the twin seal orbit valve is fully open, the plug channel aligns with the valve body channel, ensuring the ideal minimum pressure. Turning the handwheel moves the plug towards the valve, causing the valve disc to rotate 90 degrees. As the handwheel continues to rotate, the plug is pressed down, sealing both sides of the valve, and pressing the valve disc tightly against the valve seat, thereby closing the valve. Rotating the handwheel in the opposite direction first lifts the plug, releasing the valve disc from the seat. Continued rotation drives the plug to rotate the valve disc 90 degrees, aligning the plug channel with the valve body channel, fully opening the valve.

Technical Specifications

» Structure: Twin Seal Orbit Plug Valve

» Nominal Diameter: NPS 2-36 Inch (DN50-DN900)

» Design Pressure: Class 150-900 LB(PN20-PN150)

» Materials: ASTM A216 WCB, WCC, A217 WC6, WC9, C5, A352 LCB, LCC, A351 CF8, CF8M, CF3, CF3M, CF8C

» Design Standards: API 6D, API 599

» Face-to-Face: ASME B16.10

» Connection Ends: RF, RTJ

» Test Standards: API 598, ISO 5208

» Design Temperature: -46°C to +300°C

» Applicable Mediums: Water, steam, oil, gas, etc.

» Operation: Lever, Gearbox, Electric, Pneumatic, Hydraulic

Product Features

This product boasts a rational structure, reliable sealing, outstanding performance, and an aesthetically pleasing appearance. The sealing mechanism is achieved through precision-engineered sealing rings around the valve disc. It features a unique design with a swallow-tailed sink and fixed sealing rings, providing enhanced protection and durability.

A key characteristic of this product is its double-direction flow capability, which simplifies installation and enhances usability. The materials used for the components and the dimensions of the flanges can be tailored to match specific operational conditions or customer requirements, ensuring that the product meets a wide range of engineering needs.