Ball Float Steam Traps are vital for managing condensate and improving efficiency in steam systems. With a simple, durable design, they operate based on buoyancy, automatically discharging condensate while preventing steam leakage. Available in various types, they suit different industrial applications, ensuring optimal performance. Proper selection and maintenance enhance their reliability and energy-saving benefits, achieving significant cost reductions and environmental gains.

In industrial production, steam systems play a crucial role, and Ball Float Steam Traps are indispensable components within these systems. Acting like a diligent housekeeper, they carefully manage condensate, air, and carbon dioxide in the steam system, ensuring the entire system operates efficiently, energy-saving, and stably. Today, let us take an in-depth look at the advantages and characteristics of Ball Float Steam Traps, as well as how to select them correctly to meet the needs of different steam-heated equipment.

During the operation of a steam system, a large amount of condensate is generated, along with air and carbon dioxide. If these substances are not promptly discharged, they will seriously affect the normal operation of the steam system, reduce heating efficiency, and may even pose safety hazards. The basic mission of Ball Float Steam Traps is to quickly discharge these unwanted impurities while, like a loyal gatekeeper, maximizing the automatic prevention of steam leakage, ensuring that steam is efficiently used for heating equipment, and achieving effective utilization of energy.

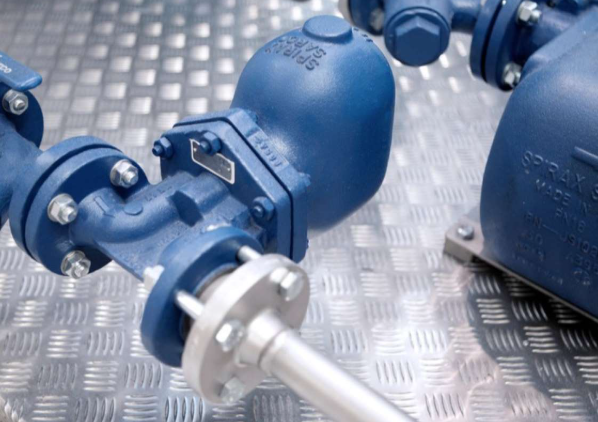

The structural design of Ball Float Steam Traps is simple yet ingenious, with only one moving part inside: a finely ground stainless steel hollow float. This float is not simple, it serves both as a buoy and as a valve actuator, achieving two functions in one. With no complex wear-prone components, the service life of the Steam Traps is greatly extended, reducing maintenance and replacement frequency, thereby saving enterprises cost and time.

Taking the YQ Steam Trap as an example, it is equipped internally with a Y-series automatic air vent, which is extremely sensitive. When the equipment starts working, the air in the pipeline is quickly discharged through this automatic air vent. Then, low-temperature condensate enters the trap. As the condensate level rises, the float rises accordingly, the valve opens, and the condensate is rapidly discharged. Steam quickly enters the equipment, and the equipment temperature rises rapidly. At this time, the temperature-sensitive liquid in the Y-series automatic air vent expands, closing the air vent. The trap begins to operate normally, and the float adjusts the valve opening according to the rise and fall of the condensate level, achieving the function of preventing steam escape while discharging water.

The free-float Ball Steam Trap further maximizes this structural advantage. Its valve seat always remains below the liquid level, forming a natural water seal that effectively prevents steam leakage, achieving remarkable energy-saving effects. Moreover, its working pressure range is very wide, from 0.01 MPa to the maximum working pressure, without being affected by temperature or pressure fluctuations, allowing continuous and stable drainage. It can discharge condensate at saturation temperature, with a minimum subcooling of only 0°C, meaning that heating equipment essentially does not retain water, achieving optimal heat transfer efficiency. With a backpressure ratio greater than 85%, it is one of the most ideal steam traps for heating equipment in production processes.

The working principle of Ball Float Steam Traps is based on buoyancy. When condensate enters the valve body, the float moves up and down with the water level. When the water level rises, the float rises, driving the valve core away from the valve seat, the valve opens, and condensate is discharged. When the water level drops, the float also drops, the valve core returns to the valve seat, the valve closes, and steam leakage is prevented. This buoyancy-driven automatic control of valve opening and closing enables Ball Float Steam Traps to operate stably and efficiently.

At the initial stage of system startup, there is air and low-temperature condensate in the pipeline. The manual air vent quickly discharges these non-condensable gases, allowing the trap to enter its working state smoothly. As low-temperature condensate flows in, the float rises, the valve opens, and condensate is discharged. Before the pipeline temperature rises to the saturation temperature, the automatic air vent has already closed. During normal operation, as the amount of condensate decreases and the liquid level falls, the float rises and falls accordingly, adjusting the valve orifice flow. When condensate stops entering, the float approaches the valve seat, closing the valve.

Ball Float Steam Traps are mainly divided into free-float, semi-free-float, and lever-type traps.

Free-Float Ball Steam Trap: As mentioned above, it has a simple structure. The valve opening is directly controlled by the float's vertical movement. It has excellent drainage performance, can handle large condensate flows, and is suitable for various occasions requiring continuous drainage.

Semi-Free-Float Ball Steam Trap: Its structure differs slightly, combining characteristics of free-float and lever-type traps. Under certain working conditions, it can provide unique advantages, for example, performing better when handling condensate containing impurities.

Lever-Type Ball Steam Trap: Uses the lever principle to amplify the buoyancy of the float, enabling control of a larger valve opening. Its advantage is that it is unaffected by pressure, temperature, or condensate flow fluctuations, allowing continuous drainage, discharging water as it forms, with a minimum subcooling of 0°C, achieving optimal heating equipment efficiency. Its valve seat is also submerged, forming a water seal to effectively prevent steam leakage.

Ball Float Steam Traps are widely used in industrial steam-heated equipment, such as large heat exchangers, dryers, and jacketed kettles. They are especially indispensable in applications with particularly high condensate discharge volumes. In these devices, Ball Float Steam Traps ensure timely condensate removal, prevent internal water accumulation, improve heat transfer efficiency, and guarantee smooth production processes.

For example, in a large heat exchanger, steam transfers heat to the medium to be heated, producing condensate that must be promptly discharged. Ball Float Steam Traps, with excellent drainage capacity and stable performance, ensure the internal heat exchanger maintains good heat transfer conditions, improving energy utilization and reducing production costs.

When selecting a Ball Float Steam Trap, the primary principle is to ensure its performance meets the optimal operating requirements of the steam-heated equipment. Only in this way can equipment operate efficiently and in an energy-saving manner. After meeting this basic condition, other objective factors, such as price, brand, and after-sales service, can be considered. Correct selection methods include:

Understanding Equipment Requirements: Before selection, clearly understand the operating parameters of the steam-heated equipment, including working pressure, temperature range, and condensate volume. Based on these parameters, determine the trap's specifications and model. For example, if the equipment has a large condensate discharge, a high-capacity Ball Float Steam Trap should be chosen.

Considering Working Environment: The working environment affects trap performance and lifespan. For low-temperature environments, insulation measures are needed to prevent freezing. For high-pressure differential operation, choose a suitable trap model to ensure proper function.

Brand and Quality: Choosing a trap from a well-known brand typically provides reliable quality and comprehensive after-sales service. Reputable brands often have strict quality control, multiple inspections, and testing, ensuring stable performance. Good after-sales service ensures timely resolution of issues, reducing downtime.

Cost-Effectiveness: Within the requirements of equipment performance and quality, cost-effectiveness is also important. Prices vary across brands and models; a comprehensive evaluation of performance, service life, and price is required to select the most cost-effective product. However, never sacrifice quality for cost savings, as this may cause greater loss to equipment and production.

Regular maintenance is essential to ensure long-term stable operation of Ball Float Steam Traps:

Regular Inspection: Check for external damage, corrosion, and loose connections. Observe the drainage status to ensure normal condensate discharge without blockage.

Cleaning and Clearing: If drainage is obstructed, internal debris or dirt may need to be removed. Disassemble the trap and rinse internal components with clean water, protecting key parts such as the float.

Insulation Measures: For traps in low-temperature environments, use insulation materials to prevent freezing. Consider installing auxiliary heat-assisted traps to improve system reliability.

Timely Replacement: If faults occur, such as float damage or incomplete valve closure, replace the trap promptly with compatible parts, following proper installation procedures.

In today's context of rising energy demand and stricter environmental requirements, the energy-saving benefits of Ball Float Steam Traps are particularly significant. They effectively prevent steam leakage, maximizing the use of steam energy and improving energy efficiency. According to statistics, steam systems using Ball Float Steam Traps achieve energy savings of 15%–30% compared with other trap types, saving substantial energy costs and reducing greenhouse gas emissions.

A chemical enterprise uses large amounts of steam-heated equipment. Before adopting Ball Float Steam Traps, poor drainage performance caused internal water accumulation, low heat transfer efficiency, and severe energy waste. Frequent trap replacement also increased maintenance costs. After detailed research and evaluation, the enterprise installed Ball Float Steam Traps. Post-installation, heat transfer efficiency improved, energy consumption decreased significantly, and trap stability and durability reduced maintenance workload, ensuring continuous production. After one year, energy costs decreased by approximately 20%, and maintenance costs dropped by around 30%, achieving remarkable economic and environmental benefits.

Ball Float Steam Traps, with their simple structure, stable performance, strong drainage capacity, and energy-saving effects, play a crucial role in steam systems. Proper selection and use can improve the operational efficiency of steam-heated equipment, reduce energy consumption, lower maintenance costs, and enhance production reliability. In the pursuit of efficiency, energy saving, and environmental protection in modern industrial production, Ball Float Steam Traps are undoubtedly indispensable energy-saving guardians in steam systems. Understanding them thoroughly helps enterprises make informed decisions, achieving both economic and environmental benefits.