As one of the most commonly used shut-off valves in industrial pipeline systems, gate valves come in diverse structural forms. Different types of gate valves have their own advantages in sealing methods, operational characteristics, and applicable working conditions. Among many designs, wedge gate valves and slab gate valves have become the two most widely used types in the industrial field due to their unique structural features and excellent sealing performance. To help select the valve solution that best matches the working conditions, it is necessary to thoroughly understand the structural design, operational characteristics, and sealing maintenance requirements of these two types of gate valves. The following provides a systematic analysis of wedge gate valves and slab gate valves, offering a reliable reference for engineering selection.

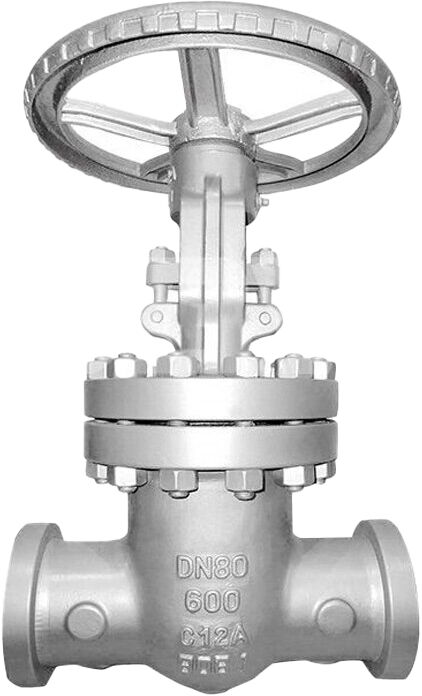

The core of a wedge gate valve lies in its unique wedge-shaped gate design. The sealing surface of this gate is wedge-shaped, forming a certain angle with the centerline of the gate. When the valve stem pushes the gate to close, the positive pressure on the wedge-shaped sealing surface increases with the applied thrust, forming a forced seal. This design greatly improves sealing performance for low-pressure media, ensuring good sealing under various low-pressure conditions.

The gate of wedge gate valves has three main structural forms: single wedge gate, flexible wedge gate, and double wedge gate.

Single Wedge Gate: This is the most basic form, with a simple structure suitable for general working conditions. The valve stem's thrust acts directly on the gate to achieve sealing.

Flexible Wedge Gate: This is a clever improvement based on the single gate. An annular groove is machined on the vertical bisector of the gate, leaving only the central part connected, giving the gate sealing surface a certain elastic deformation capability. This elastic deformation allows the gate to automatically compensate for angular deviations between the gate and seat during closure, further enhancing the sealing effect. It is especially suitable for high-temperature pipelines. When high-temperature media cause expansion of the gate, valve stem, and other components, the elastic deformation of the flexible gate can effectively prevent jamming with the seat, ensuring normal gate operation and greatly improving valve reliability and service life.

Double Wedge Gate: This separates the central connection of the flexible wedge gate, forming two independent gates on the inlet and outlet sides. These two gates are hinged with spherical pivots to form a wedge gate. When closing, the spherical pivot structure between the inner surfaces of the gates gradually reduces the distance as the gate descends, forcing both gates outward so that the sealing surfaces on the inlet and outlet ends are tightly pressed against the seat, achieving sealing. This design not only further enhances sealing and reduces internal leakage but also prevents jamming under temperature changes and effectively reduces wear on the sealing surfaces. However, the structure is relatively complex, more costly, and prone to sticking in crystallizing or viscous media, affecting sealing performance.

Wedge gate valves rely on the valve stem to push the wedge gate downward to achieve forced sealing, so the operating torque required is relatively large. During closure, a torque switch controls the process to maintain a certain torque, ensuring the valve stem continues to push the gate and exert sufficient sealing pressure on the seat, thereby ensuring sealing performance. This design provides reliable sealing but requires considerable effort during operation, which may be inconvenient, especially for manual operation.

Moreover, in the closed state, if the temperature rises excessively, the valve stem may expand due to heat, potentially causing the gate to jam and preventing normal opening. Therefore, when using wedge gate valves in high-temperature environments, attention must be paid to temperature effects, and measures should be taken to prevent failures caused by temperature changes.

The gate and seat of wedge gate valves are separated when the valve is open, which reduces wear on the sealing surfaces to some extent. However, particulate media may enter the sealing surfaces when closed, leading to imperfect sealing and possible damage. Therefore, wedge gate valves should be avoided in conditions with particulate media or effective filtration measures should be applied.

For maintenance, the packing seal position and gate sealing generally do not require additional grease. This is because the sealing principle relies on the valve stem thrust and wedge structure of the gate, rather than grease, to achieve sealing. Nevertheless, regular inspection of packing wear and timely replacement is necessary to ensure sealing performance and operational flexibility.

Unlike the wedge gate of wedge gate valves, the sealing surfaces at the inlet and outlet ends of slab gate valves are parallel to the centerline of the gate, forming a simple slab shape. This design makes slab gate valves relatively simple in structure, easier to operate, and with lower fluid resistance, effectively reducing pressure loss in the pipeline system.

Slab gate valves have two forms: single gate and double gate.

Single Gate: Sealing is mainly achieved by the medium pushing a floating gate or floating seat.

Double Gate: Sealing can be achieved through springs or spreading mechanisms between the gates. During operation, the sealing surfaces of the gate and seat remain closely fitted, giving slab gate valves unique advantages in sealing, especially under particulate media conditions. This effectively prevents particles from entering the sealing surface, reducing wear and extending valve life.

Additionally, the slab gate may have flow-through holes. Gates with holes matching the seat inner diameter facilitate pipeline cleaning and allow a straight, smooth passage when fully open, reducing flow resistance and enabling cleaning balls to pass, significantly improving pipeline maintenance convenience and operational efficiency.

Slab gate valves offer low valve stem torque and flexible closure control. Sealing is achieved by medium pressure pressing the gate against the seat, requiring less effort, making manual or electric operation effortless.

Closure is controlled via a position switch, requiring only control of gate position, making the operation simple and reliable, more intuitive than the torque switch control of wedge gate valves. Since valve stem expansion does not affect gate sealing, jamming is avoided, providing better stability and reliability under high temperatures.

The sealing performance of slab gate valves is mainly due to their unique sealing structure. The seat uses a ring seal and a preloaded floating seat structure, achieving bidirectional sealing, with opening and closing torque only half that of ordinary valves, allowing easy operation. Seat surfaces may have stainless steel or cobalt-chromium-tungsten overlays, providing metal-to-metal double sealing while cleaning the gate surface, further improving sealing and service life.

Adding grease to the packing during maintenance enhances lubrication, reduces wear, and improves sealing, while the self-sealing packing design requires minimal adjustment, enabling smooth, reliable operation. Auxiliary grease injection ports further ensure sealing reliability, achieving near-zero leakage and solving common packing leakage problems in conventional valves.

Choosing the appropriate gate valve is crucial in practice. Wedge gate valves and slab gate valves have different advantages suitable for different conditions:

Wedge Gate Valves: With their unique wedge design, they excel in sealing low-pressure media, especially where forced sealing is required. Flexible and double wedge gates can compensate for machining errors, adapt to high temperatures, and reduce sealing surface wear. However, they may stick in crystallizing or viscous media, are structurally complex, and costlier. They are more suitable for applications requiring high sealing performance, large temperature variations, and low or minimal particulate content.

Slab Gate Valves: With a simple and efficient structure and low fluid resistance, they are advantageous for frequent operation and particulate-laden media. Continuous engagement of gate and seat prevents particle intrusion, reduces wear, and extends service life. Operation is easy, maintenance is convenient, and they are suitable for controlling various media, especially under frequent switching and high sealing surface wear. However, manufacturing is more complex, costs are higher, and their size requires sufficient installation space.

As indispensable components in industrial pipeline systems, wedge gate valves and slab gate valves each have their own characteristics. Wedge gate valves excel in low-pressure media sealing and high-temperature adaptability with multiple gate forms, but are complex, costly, and may stick in crystallizing or viscous media. Slab gate valves feature simple, efficient structure, low fluid resistance, and superior adaptability to particulate media, showing clear advantages in frequent operation and particulate-laden conditions. Though manufacturing is complex and costly, maintenance is convenient, and service life is long.

When selecting a gate valve, it is necessary to consider medium properties, temperature, pressure, particulate content, and operating frequency to choose the most suitable type and structural form. Only by doing so can the valve achieve optimal performance, ensuring the safety, stability, and efficiency of the pipeline system. Both wedge gate valves and slab gate valves are indispensable guardians of industrial pipelines, providing reliable control over fluid flow.