In the field of industrial automation control, control valves play an indispensable role. They act as precise flow regulators, adjusting the fluid flow by controlling the valve opening and closing, thereby achieving precise control of the production process. The flow characteristics of a control valve are one of its core performance indicators, directly determining how the valve performs under different working conditions. Today, we will take an in-depth look at the flow characteristics of control valves and how to select the right flow characteristic based on actual needs to ensure efficient operation of the control system.

The flow characteristics of a control valve are mainly divided into two categories: ideal flow characteristics and working flow characteristics.

The ideal flow characteristic refers to the relationship between flow rate and valve opening when the pressure difference at the inlet and outlet of the control valve remains constant. This characteristic is obtained under ideal conditions and is mainly used for theoretical analysis and preliminary selection. The working flow characteristic refers to the relationship between flow rate and valve opening under actual operating conditions, where the pressure difference across the valve changes. In practice, we pay more attention to the working flow characteristic because it is closer to the real situation.

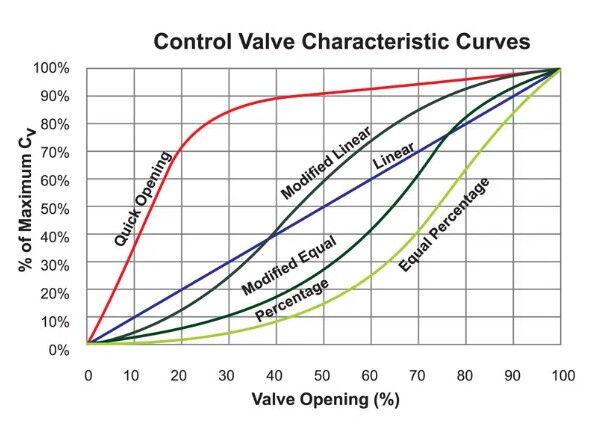

There are four common types of ideal flow characteristics: linear, equal percentage, parabolic, and quick-opening.

The linear flow characteristic is the most straightforward. It indicates that the relative flow rate and relative valve opening are in a linear relationship. In other words, for every small increase in valve opening, the flow rate increases by a fixed proportion. This characteristic means that at small openings, the flow rate changes significantly, providing high sensitivity, while at large openings, the flow rate changes less, making control less effective. For example, in a system requiring fine control of small flow, the linear characteristic may cause oscillation due to high sensitivity; in a large flow system, it may respond slowly. Therefore, linear flow characteristics are suitable for conditions where the differential pressure change is small, process parameters vary linearly, system pressure loss is mainly concentrated on the control valve, and external disturbances are minor.

The equal percentage flow characteristic is more flexible. It indicates that the relative change in flow caused by a unit change in valve travel is proportional to the relative flow rate at that point. This means that regardless of the valve opening, the percentage change in flow is the same. This characteristic provides stable operation throughout the full stroke and is especially sensitive and effective at large openings. Therefore, equal percentage flow characteristics are suitable for applications with large adjustable ranges, relatively large pressure changes across the valve, high pipeline pressure losses, and significant process load fluctuations. It is widely used in practical applications due to its strong adaptability.

The parabolic characteristic lies between the linear and equal percentage characteristics. Its control performance is relatively ideal, but due to the difficulty of manufacturing the valve plug, it is usually replaced by the equal percentage characteristic. The parabolic characteristic can be chosen for situations requiring high control accuracy but should be balanced against manufacturing cost and convenience.

The quick-opening characteristic is a special type. It means that at small valve travels, the flow increases rapidly and soon reaches its maximum value. In other words, at small openings, the flow is already high, and as travel increases, the flow quickly reaches its maximum. Therefore, quick-opening flow characteristics are generally used in on-off control and program control systems, such as those requiring rapid switching, where the quick-opening valve can achieve large flow changes rapidly.

In actual systems, the pressure drop across the valve is not constant. This variation is mainly caused by two factors: First, the pump characteristic: when system flow decreases, the pressure generated by the pump increases; Second, the change in pipeline resistance: when flow decreases, pipeline resistance decreases, resulting in a greater pressure drop across the valve.

Therefore, the pressure difference between the valve inlet and outlet usually changes, and the flow–opening relationship under these conditions is the working flow characteristic. Working flow characteristics can be divided into two types: those for series pipeline systems and those for parallel pipeline systems.

When the control valve is connected in series with the pipeline, changes in valve opening cause changes in flow rate. According to fluid mechanics theory, the pipeline resistance loss is proportional to the square of the flow rate. When the valve operates and changes the flow, the system resistance also changes, which alters the pressure drop across the valve. In this situation, the working flow characteristic is related to the pressure drop distribution ratio. If the valve pressure drop is small, the full-open flow of the valve decreases accordingly, and the ideal linear characteristic may distort into a quick-opening characteristic, while the ideal equal percentage characteristic may distort into a linear characteristic. In actual use, if the control valve is oversized or the system operates under partial load, the valve may work at small openings. To increase the valve opening, sometimes operators intentionally reduce valve opening to increase pipeline resistance and decrease the flow through the valve. However, this reduces the pressure drop distribution ratio, causing flow characteristic distortion and worsening control quality.

When the control valve is installed in parallel with the pipeline, the system usually consists of a valve branch and a bypass branch, with the valve located in the valve branch. In this case, as the bypass valve gradually opens, the ratio of the valve's full-open flow to the total maximum flow decreases. Although the valve's own flow characteristic remains unchanged, the system's adjustable range is greatly reduced, limiting the valve's controllable flow variation. To maintain good regulating performance, the bypass flow is generally limited to no more than 20% of the total system flow.

As a terminal component in process control systems, the control valve is a common actuator. According to process control requirements, the control valve should operate with low energy consumption while matching the system characteristics. However, these two requirements often conflict.

For example, to achieve the same flow rate, selecting a smaller control valve will increase total system resistance and pressure drop, meaning that if the flow is driven by a pump, a larger pump and motor will be required, leading to higher energy consumption.

When the flow velocity in the pipeline increases, the fluid pressure drop caused by fittings and equipment in the pipeline changes dynamically.

As the primary flow control element, the control valve causes a significant and often overlooked pressure drop. When analyzing system problems related to control valves, it is essential to consider not only the valve itself but also the effect of its pressure drop on system dynamic balance.

The pressure drop ratio (S) of a control valve is defined as the ratio of the pressure difference across the valve at maximum controllable flow (ΔP₁m) to the total system pressure difference (ΔP).

The magnitude of S directly affects the valve's flow characteristic and control performance.

For example, in a linear valve, the flow change at small openings is large, making it too sensitive and prone to oscillation; at large openings, the control response is weak and slow. Therefore, linear valves are unsuitable when S is small, and load variation is large.

In contrast, an equal percentage valve operates smoothly near closure and sensitively near full opening, making it suitable for systems with large load variations.

The methods for selecting flow characteristics are mainly divided into two types: the analytical method and the empirical method. Since the analytical method is complex and time-consuming, the empirical method is generally adopted in engineering practice. Specifically, selection should consider control quality, operating conditions, load variation, and characteristic requirements.

According to the principle of characteristic compensation in automatic control theory, to maintain good control quality, the product of the open-loop total gain and the gain of each link should remain constant. By appropriately selecting the valve characteristic, changes in the valve gain can compensate for variations in process gain, keeping the total system gain constant. For example, if the process characteristic is linear, a linear flow characteristic valve can provide a better match; if the process characteristic is nonlinear, an equal percentage valve may be more appropriate.

Operating conditions include variations in system pressure, flow, and temperature. For example, in a system with large pressure fluctuations, choosing an equal percentage valve allows better adaptation to pressure changes; in a system with small and stable flow variations, a linear valve is more suitable. It is also important to consider external disturbances. If the system is subject to large external disturbances, a valve with more stable and sensitive regulation should be chosen.

Load variation refers to changes in parameters such as flow or pressure caused by production demand changes during operation. For systems where load frequently fluctuates, an equal percentage valve provides smoother control and maintains stable operation; for systems with small load variation, a linear valve may be sufficient.

Characteristic requirements refer to the specific flow characteristic requirements of the process system. For example, in a system requiring fast regulation, a quick-opening characteristic may be appropriate; in systems requiring fine adjustment, an equal percentage characteristic is preferable. In addition, the valve's sealing structure should be considered. If high flow characteristic accuracy is required, metal-seated valves with high precision should be selected; if accuracy requirements are lower, soft-seated valves can be chosen to reduce costs.

To better understand the selection of control valve flow characteristics, let's examine a practical case. Suppose there is a chemical production system that requires precise control of the liquid flow into a reactor. The system parameters change linearly, most pressure loss is concentrated on the control valve, external disturbance is minimal, and load variation is small. In this case, a linear flow characteristic valve is initially selected to provide stable regulation and meet precise flow control requirements. However, during actual operation, slight oscillation occurs at small openings. Analysis reveals that this is due to excessive sensitivity of the linear characteristic at small openings. To solve the problem, the flow characteristic is changed to an equal percentage type. The equal percentage characteristic offers smoother control at small openings and effectively prevents oscillation. After adjustment, the system's performance improved significantly, and control quality increased.

The flow characteristic of a control valve is one of its core performance indicators, directly determining how it performs under various working conditions. Selecting an appropriate flow characteristic requires comprehensive consideration of control quality, operating conditions, load variation, and characteristic requirements. In engineering practice, the empirical method is generally used for selection, analyzing the system's actual needs to choose the most suitable valve characteristic. At the same time, it is necessary to consider the influence of valve pressure drop on system dynamic balance to ensure proper matching between valve and system, achieving efficient and stable operation.

In summary, the selection of control valve flow characteristics is a systematic engineering process that requires consideration of multiple factors. Only through scientific and rational selection and optimization can the control system maintain good performance under all operating conditions and meet the needs of production processes. It is hoped that this article will help you better understand and apply control valve flow characteristics, providing strong support for your industrial automation control projects.