In industrial operations, valves are critical components within pipeline systems. Their quality, reliability, and performance directly affect the safety, efficiency, and stability of entire industrial processes. To standardize and ensure the quality of valves, the American Petroleum Institute (API) has established a series of valve standards that govern design, manufacturing, testing, installation, and maintenance. These standards provide comprehensive and rigorous guidelines to ensure that valves perform reliably and safely under a variety of challenging operating conditions.

API standards are not limited to a single document; rather, they encompass a series of regulations that address the full lifecycle of industrial valves. Among these, over a dozen core standards directly relate to industrial valves, each targeting specific valve types, sizes, and operating conditions. This article focuses on the most widely applied and influential standards: API 6D, API 600, API 602, API 598, and API 6FA, along with their practical industrial applications.

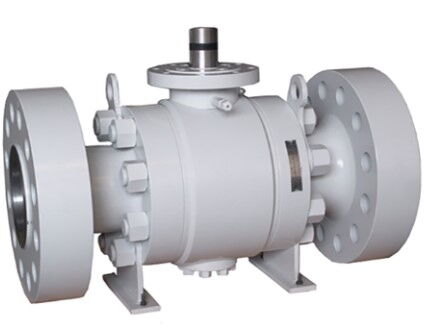

API 6D is recognized globally as the authoritative standard for pipeline valves, widely adopted in long-distance oil and gas pipelines, gathering networks, and other large-scale transport systems. It covers gate valves, ball valves, check valves, and plug valves, establishing essential design, material, and testing requirements. The latest edition, API 6D-2022, clearly defines the scope, design criteria, material selection, testing procedures, and marking and traceability protocols.

API 6D applies to pipeline valves with a nominal pressure of PN10 or higher and a nominal diameter (DN) of 25 or above. The standard accommodates an exceptionally broad range of operating temperatures, from -196°C for cryogenic LNG pipelines to 1,200°C for high-temperature steam lines. This extensive coverage ensures that valves meeting API 6D standards are suitable for diverse environmental and process conditions, providing versatility across multiple industrial sectors.

Fire-safe design is a central requirement of API 6D, distinguishing pipeline valves from ordinary industrial valves. Valves must maintain basic sealing capability after exposure to fire, preventing the uncontrolled release of hazardous media and minimizing potential safety incidents. For instance, an API 6D-compliant valve can effectively block the leakage of flammable or explosive substances during a fire, granting critical time for firefighting and personnel evacuation.

Material selection under API 6D is also highly prescriptive, accounting for corrosion and specific environmental factors. For example, in H₂S-containing acidic environments, valve bodies are required to use sulfur-resistant steel (e.g., A105N with anti-sulfur heat treatment), while sealing surfaces must be constructed from corrosion-resistant alloys such as Inconel 625. This rigorous material specification ensures durability and reliability under aggressive service conditions.

Each API 6D valve must undergo shell pressure testing and seat leakage testing, with test pressures reaching 1.5 times the nominal pressure for the body and 1.1 times for the seat. Low-temperature valves additionally require cryogenic leakage tests, while high-pressure valves undergo life-cycle testing, typically involving 1,000 full-stroke cycles to ensure continued sealing performance. These stringent tests verify valve performance and quality from multiple perspectives.

API 6D valves are predominantly used in long-distance oil and gas pipelines. For example, large-diameter ball valves (DN 1,400 and above) in China's West–East Gas Pipeline system must comply with API 6D and carry the API Monogram certification. Manufacturers are first required to achieve API Q1 quality system certification before applying for API 6D product certification, ensuring both product quality and consistency.

API 600 specifically addresses gate valves, which are widely used in petrochemical processes, oil refining, and chemical plant piping. Its defining features are high reliability and long operational life, making it essential for critical process lines.

API 600 emphasizes the use of rising stem gate valves, where the valve stem rises with the gate, allowing operators to visually confirm valve position. This design prevents misinterpretation of the valve's open or closed state, a common risk in non-rising stem designs where corrosion or wear may obscure stem movement. This is particularly significant in complex refining environments, enhancing operational safety and accuracy.

Valve bodies and bonnets must meet API 5L (pipeline steel standard) or ASTM standards, with wall thickness designed according to Pressure-Temperature Ratings (P-T Ratings). This ensures valves can withstand the nominal pressure at the highest operating temperature, meeting the requirements of high-temperature, high-pressure applications.

API 600 gate valves must provide bidirectional sealing, allowing media to flow and be sealed from both ends. Valve seats are typically hard-faced with Stellite 6, improving wear and corrosion resistance. This combination of sealing design and material selection ensures reliable performance even in challenging process conditions.

Testing requirements go beyond conventional shell and seat testing. Stem packing tests are also mandated: the valve stem is cycled ten times at nominal pressure, and no visible leakage is allowed at the packing gland. This test addresses frequent operational scenarios in refinery systems, preventing leaks due to stem seal failure and enhancing overall reliability and safety.

API 600 gate valves are commonly found in atmospheric and vacuum distillation units, as well as fluid catalytic cracking units. For instance, high-temperature heavy oil pipelines at the bottom of atmospheric distillation towers (around 350°C) require chromium-molybdenum steel gate valves (e.g., A351 CF8M) that meet API 600, providing both high-temperature strength and erosion resistance. The high reliability and long service life of these valves contribute significantly to the stable operation of refineries.

Unlike API 600, which addresses large, high-pressure gate valves, API 602 focuses on small-diameter, compact gate valves, covering nominal sizes DN10-DN50 and pressures PN16-PN420. The latest version is widely applied in instrumentation lines, sampling lines, and other space-limited pipelines.

API 602 requires end-to-end lengths to be 30–50% shorter than equivalent API 600 valves. For example, a DN25, PN100 API 602 gate valve is only 140 mm long, ideal for compact instrument cabinets.

The standard allows for lighter valve body materials (e.g., forged steel A105), provided that stress analysis confirms structural integrity under high-pressure conditions. This balance between material strength and compact design ensures both space efficiency and operational reliability.

API 602 supports threaded connections (NPT) and socket weld connections, eliminating the need for flanges and further reducing pipeline footprint.

Given the lower risk associated with small-diameter lines, API 602 allows 10% batch sampling for full performance testing, though critical sealing tests must still be performed 100%. This approach ensures quality while improving manufacturing efficiency.

API 602 gate valves are typically used in instrumentation loops in petrochemical facilities. For instance, sampling lines for online analyzers (e.g., gas chromatographs) often require DN 15 threaded API 602 valves, which meet sealing requirements while minimizing installation space. This supports efficient operation in confined areas of complex processing plants.

API 598 serves as the general testing guideline for all API-compliant valves, regardless of type, gate, ball, or check valves. The standard ensures consistent, objective test results across all valve types, promoting reliability and quality assurance. The latest edition is API 598-2021.

API 598 divides valve testing into:

Manufacturer Testing: Required for every valve before shipment.

Type Testing: Conducted when a new product or material is introduced.

Manufacturer tests include:

Shell Test: Conducted with water or corrosion-inhibited liquid at 1.5 times nominal pressure. Holding times vary with size: DN ≤ 50: 10 minutes, DN ≥ 600: 30 minutes. No visible leaks at the body or bonnet are allowed.

Seat/Seal Test: Conducted with water or air (for low-pressure valves), at 1.1 times nominal pressure. Seat and stem packing must be leak-free, with ≤1 bubble per minute during air testing.

Operational Test: Manual or powered operation, full open/full close 3 cycles, ensuring smooth, accurate, and responsive movement.

If a valve fails any test, a single repair attempt is permitted (e.g., seat grinding, packing replacement). After repair, all tests must be repeated. Failure after repair leads to mandatory rejection, preventing defective valves from leaving the factory. This strict process guarantees the quality and reliability of API-certified valves.

Fire-safe design is mandatory in oil and gas applications, and API 6FA is the globally recognized standard for fire-testing valves. The latest edition is API 6FA-2019, focusing on post-fire sealing capability.

Valves are mounted in a test pipeline in partially open position, simulating real fire scenarios. The line is filled with water or nitrogen at nominal pressure. Propane flames heat the valve to 925–1,095°C, simulating petroleum fires.

The heating process has two stages:

Sustained Heating: 30 minutes, monitoring for structural failure (body rupture, stem bending).

Post-Fire Quenching: Immediate cold water spray for 15 minutes, simulating firefighting, while monitoring sealing performance.

Requirements include: no structural damage, pressure drop ≤ 1% per minute, normal operation (full open/close), and no visible leakage (≤3 bubbles/minute during air testing).

Valves certified under API 6FA are labeled "API 6FA" and are used in high fire-risk areas such as:

Wellhead Christmas trees

Subsea pipelines

LNG storage tanks

For example, offshore oil platform valves must maintain sealing after a fire, allowing safe evacuation and firefighting, significantly improving safety in hazardous environments.

The suite of API valve standards provides a comprehensive framework covering the full lifecycle of industrial valves, from design and material selection to testing, installation, and maintenance. Standards like API 6D for pipeline valves, API 600 for high-temperature, high-pressure gate valves, API 602 for compact small-diameter valves, API 598 for general testing procedures, and API 6FA for fire-safe performance collectively ensure that valves meet stringent reliability and safety criteria.

By adhering strictly to these standards, manufacturers can produce high-quality, high-performance valves, while end-users gain confidence in valve performance and safety, supporting stable industrial operation and protecting personnel.

In practice, whether it is large-diameter ball valves in long-distance pipelines, high-temperature gate valves in refinery heavy oil lines, or compact instrumentation gate valves in petrochemical systems, API-compliant valves deliver exceptional performance and reliability, playing a vital role in industrial safety and operational continuity.