Valve sealing is a critical component in preventing medium leakage and ensuring the safe operation of industrial equipment. The performance of valve sealing is influenced by factors such as the gap between sealing components, pressure differences, and the physical properties of the medium. Liquid and gas sealing mechanisms differ due to factors like viscosity, surface tension, and gas molecule movement, which impact leakage behavior. Key aspects such as sealing surface structure, wear, and material selection also play vital roles in sealing efficiency. Temperature variations, sealing force, and medium characteristics further affect the performance of valve seals. Proper design and material choice are essential for achieving durable, reliable sealing, which helps prevent leakage, reduce energy and material waste, and mitigate safety risks.

The primary task of valve sealing is to prevent medium leakage, and research on valve sealing fundamentally revolves around this objective. Leakage issues typically stem from two factors: first, the gap between the sealing pair, and second, the pressure difference on either side of the sealing pair. Understanding these two critical factors is essential for improving valve sealing performance and reducing leakage.

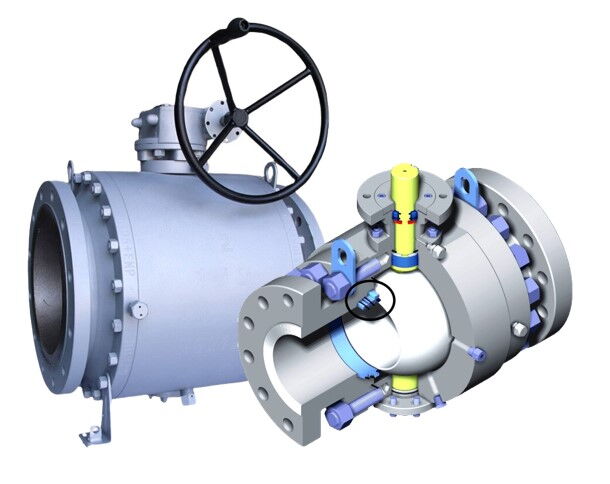

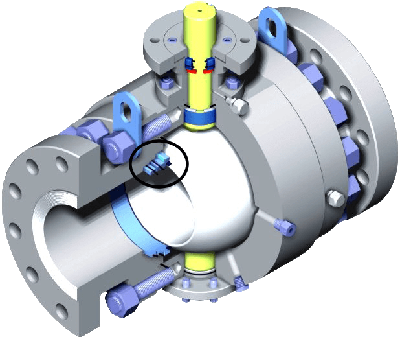

Structure and Gap of the Sealing Pair: The sealing pair refers to the sealing interface formed when the valve seat and the closing member come into contact. Ideally, the contact surfaces of these components should fit closely to achieve complete sealing. Any minute gap can lead to leakage, so the design of the sealing pair must ensure that the contact between the sealing surfaces effectively closes all passages under pressure differentials.

Influence of Pressure Difference: The pressure difference refers to the difference in medium pressure on either side of the sealing pair. When the pressure difference of the medium is significant, the sealing pair faces a higher risk of leakage. Especially when the valve is closed, the pressure difference can induce greater contact pressure on the sealing pair, so the design must consider the maximum pressure difference the sealing pair can withstand.

The sealing of liquids is primarily determined by the liquid's viscosity and surface tension. When a capillary is filled with gas, surface tension can either repel the liquid or draw it into the capillary. If the tangent angle is less than 90°, the liquid easily enters the capillary and causes leakage; if the tangent angle is greater than 90°, the liquid is repelled, but if there is a film of grease or wax on the surface, the dissolution of these substances can lead to liquid penetration.

Liquid Sealing Experiments: Different media exhibit different leakage behaviors under the same conditions. For example, the sealing test results for water, air, or kerosene may vary. The Poisson formula indicates that reducing the capillary diameter and using a liquid with higher viscosity can effectively reduce leakage.

The sealing of gases is influenced by the movement and viscosity of gas molecules. When gas passes through a capillary, the leakage amount is related to the length and diameter of the capillary and the viscosity of the gas. When the capillary diameter is similar to the mean free path of gas molecules, the gas molecules freely diffuse and enter the capillary. Gas sealing tests are more stringent than liquid tests because gases can diffuse through metal walls, and even reducing the capillary diameter cannot completely prevent gas flow.

Gas Sealing Tests: Due to the diffusion characteristics of gases, even if the capillary diameter is reduced through plastic deformation, gas can still diffuse through the metal surface. Therefore, gas sealing tests require stricter control conditions than liquid sealing to ensure effective sealing.

The valve sealing surface is composed of roughness factors such as the unevenness of the waveform surface and the waviness between wave peaks. When the elastic strain force of metal materials is low, a higher compressive force is required to achieve sealing. By reasonably designing the hardness difference of the sealing pair, the sealing surface can undergo plastic deformation under pressure, thereby forming a better seal.

Wear and Plastic Deformation of Metal Sealing Surfaces: During use, valve sealing surfaces may be affected by medium entrainment, corrosion, wear particles, cavitation, and other factors. Especially, wear particles can improve the surface precision of the sealing surface if they are small, but larger particles can exacerbate wear and reduce sealing performance. Therefore, selecting appropriate materials and lubricants to avoid particle damage to the sealing surface is a crucial aspect of valve sealing design.

The performance of valve sealing is not only closely related to the design of the sealing surface itself but is also influenced by various external factors.

Temperature changes affect the sealing pair in multiple ways. Temperature increases or decreases can alter the material properties of the sealing pair and cause dimensional changes in components, affecting sealing effectiveness. Additionally, the impact of temperature on gas viscosity directly influences leakage rates. Therefore, thermal compensation designs, such as using elastic valve seat materials, should be considered in valve sealing design to maintain good sealing performance under temperature fluctuations.

The specific pressure of the sealing surface directly affects the sealing performance and service life of the valve. Excessive specific pressure can damage the valve sealing surface, while insufficient specific pressure can lead to poor sealing and leakage. Therefore, the specific pressure of the sealing surface must be appropriately selected during valve design to ensure good sealing performance under normal working pressure.

The physical properties of the medium, such as temperature, viscosity, and surface hydrophilicity, significantly impact sealing performance. Temperature changes can cause material expansion or contraction, affecting the contact surface of the sealing pair. Media with higher viscosity have lower penetration ability, which helps improve sealing. Additionally, surface hydrophilicity is a key factor in the sealing performance of metal surfaces. If the metal surface has an oil film or other contaminants, it may lead to sealing failure, so the surface must be kept clean, and appropriate materials must be selected during design.

The quality of sealing components directly determines the sealing effectiveness of the valve. Material selection should comprehensively consider corrosion resistance, wear resistance, high-temperature performance, and performance under working conditions. The design of the sealing pair should ensure that the sealing surface is flat and has high contact precision with the valve seat to enhance sealing. Material selection should also consider the service life of the sealing components to ensure long-term sealing effectiveness.

Valve leakage not only causes waste of energy and materials but can also lead to serious safety accidents. For example, in the chemical industry, leakage can result in the release of toxic, flammable, or corrosive substances, posing significant threats to personal safety and the environment. Therefore, factors preventing leakage must be fully considered during valve design and material selection to ensure the safety and reliability of valves under complex working conditions.

Valve sealing is a core element in ensuring the safe and efficient operation of equipment. Its design must consider the precision between sealing surfaces, pressure differences, temperature, medium characteristics, and other factors, while ensuring that the materials of the sealing components can withstand long-term physical and chemical effects. Through scientific design and reasonable material selection, the sealing performance of valves can be effectively improved, leakage risks can be reduced, and the normal operation and safe production of industrial equipment can be ensured.