Gate valves and globe valves are both essential components in industrial piping systems, each with distinct characteristics suited to different applications. While both control fluid flow, they operate based on different principles and offer varying performance features. This article compares gate valves and globe valves, focusing on their working principles, structural characteristics, applications, and advantages and disadvantages. Gate valves are ideal for large flow systems requiring full opening or closing, while globe valves are more suitable for precise flow regulation and throttling. Understanding the strengths and limitations of each valve type is crucial for selecting the appropriate valve for specific industrial needs.

Valves are essential components in industrial piping systems, each with distinct structural features and applications. Gate valves and globe valves are two commonly used types. While both serve the basic function of controlling and regulating fluid flow, they differ significantly in their working principles, application scope, and performance requirements. This article explores the working principles, structural characteristics, applications, and advantages and disadvantages of gate valves and globe valves.

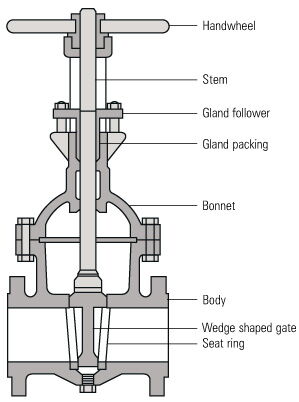

Gate Valves: Gate valves have sealing surfaces between the valve body and gate that are in continuous contact, leading to friction during opening and closing. This design makes sealing surfaces prone to wear, especially when the valve is nearly closed, where pressure differences on both sides of the gate are significant, intensifying wear. However, gate valves have a certain degree of self-sealing capability. The gate tightly contacts the seat under pressure, ensuring good sealing performance. Wedge gate valves typically have a 3°-6° slope on the gate, which may cause jamming under high-temperature or high-pressure conditions, particularly during use. To address this, wedge gate valves for high-temperature and high-pressure applications are often designed with anti-jamming features.

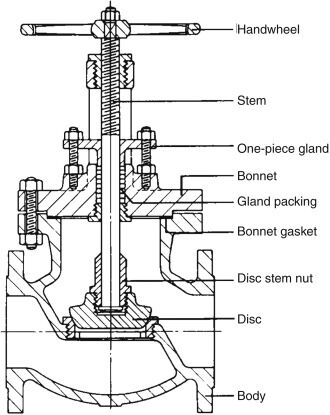

Globe Valves: Unlike gate valves, globe valves have sealing surfaces between the valve disc and seat that only make contact when fully closed, reducing friction and extending the service life of the sealing surfaces. The sealing performance of globe valves is achieved through a forced closing mechanism, making them suitable for applications requiring high sealing ability and small flow. Although globe valves experience less sealing surface wear, they can still be damaged by solid particles in the medium. Globe valves are ideal for throttling and regulating applications, but improper sealing can lead to damage if exposed to high-speed flow.

Gate Valves: Gate valves have a relatively complex structure, typically divided into rising stem and non-rising stem types. Rising stem gate valves require a large installation space, which should be considered when space is limited. Gate valves are generally not direction-sensitive, allowing bi-directional flow, providing flexibility in installation. However, their design, especially the rising stem type, often requires larger installation space.

Globe Valves: Globe valves have a simpler structure, typically offering higher sealing performance and larger opening and closing torque. Installation requires strict adherence to the flow direction, as indicated by the valve body's arrow. When the valve disc contacts the sealing surface, the movement is minimal, reducing wear and extending its service life. Proper installation ensures correct flow direction, essential for optimal sealing and performance.

Gate Valves: When fully open, gate valves present minimal resistance to flow, resulting in very low flow resistance. The flow resistance coefficient typically ranges from 0.08 to 0.12. Compared to globe valves, gate valves exhibit lower flow resistance and require smaller torque for opening and closing. As a result, gate valves are suitable for applications with large flow rates where no flow regulation is needed. However, due to their longer stroke and slower operation, gate valves are unsuitable for frequent opening and closing applications.

Globe Valves: Globe valves have higher flow resistance, typically 3 to 5 times that of gate valves. The torque required for opening and closing is greater due to the force required to compress the valve disc against the sealing surface. Globe valves are ideal for applications involving flow regulation and throttling, but their higher flow resistance and opening/closing torque make them unsuitable for rapid opening and closing or large flow applications.

Gate Valves: Gate valves are ideal for applications that require full opening or full closure, particularly in systems with large flow rates where flow regulation is unnecessary, such as in water treatment systems, large-diameter pipelines, and oil and gas transportation. The advantages of gate valves include low flow resistance and low opening torque, making them suitable for systems with large flow rates and no need for flow regulation. However, due to their longer stroke and slower operation, gate valves are not suitable for applications that require frequent flow adjustments.

Globe Valves: Globe valves are more suited for applications requiring precise flow regulation and pressure control, making them widely used in the chemical, oil, and natural gas industries, especially in systems with strict flow control requirements. Globe valves offer higher sealing performance and are ideal for fine adjustments. However, due to their larger opening/closing torque and higher flow resistance, they are typically not suitable for rapid opening and closing or large flow applications.

Gate Valves: Maintenance of gate valves usually requires removing the valve from the pipeline, making it a more complex and costly task. Over time, the sealing surfaces of the gate valve may wear or jam, necessitating regular inspection and replacement of seals. To prevent jamming, especially under high-temperature and high-pressure conditions, routine maintenance and inspection are crucial.

Globe Valves: Maintenance of globe valves is relatively simpler. In many cases, the valve seat or disc can be replaced on-site without removing the entire valve. This convenience makes globe valves easier to maintain, especially in welded pipelines or in systems with stringent pipeline requirements.

Gate valves and globe valves each have unique advantages and disadvantages. Gate valves are suitable for applications requiring full opening or closing with minimal flow resistance and lower opening torque, making them ideal for large-diameter pipelines and high-flow systems. However, they are not suitable for frequent flow adjustments. Globe valves, on the other hand, are better for precise flow regulation and pressure control, with excellent sealing performance and throttling capabilities. However, their higher flow resistance and greater opening/closing torque make them unsuitable for rapid or high-flow operations. The selection of the appropriate valve depends on the specific working conditions, fluid characteristics, and opening/closing frequency.