In fluid transportation and control systems of all kinds, valve selection has a direct impact on system safety, operational stability, and overall operating costs. As operating conditions become more diverse and reliability requirements continue to increase, valve products that combine corrosion resistance, structural reliability, and economic efficiency are receiving growing attention. Against this background, bronze ball valves have emerged as a widely adopted and representative valve type. Owing to their proven structural design and excellent material properties, bronze ball valves play an important role in marine, chemical, water treatment, and domestic water supply and drainage applications.

This article provides a systematic overview of the operating principles, material characteristics, selection criteria, application fields, and maintenance practices of bronze ball valves, helping readers gain a comprehensive understanding of their technical advantages and practical value.

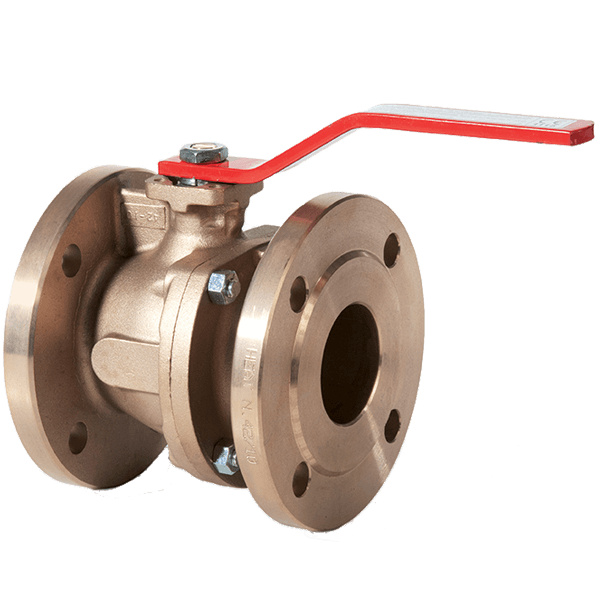

A bronze ball valve is a quarter-turn valve whose core component is a hollow spherical ball with a through-bore. By rotating the ball, the valve achieves on–off control of fluid flow. The main body material is bronze, an alloy primarily composed of copper and tin. Bronze endows ball valves with excellent strength, durability, and corrosion resistance, enabling stable operation under a wide range of complex service conditions.

The operating principle of a bronze ball valve is simple and intuitive. Inside the valve body is a centrally bored ball. When the handle or actuator is in the open position, the bore of the ball aligns with the pipeline flow direction, allowing the fluid to pass through smoothly. When the handle or actuator is rotated 90° to the closed position, the bore is perpendicular to the flow path, blocking the fluid and achieving a tight shutoff. The position of the ball determines the valve’s flow control capability.

According to bore size, bronze ball valves are generally classified into full-bore and standard-bore types.

Full-bore bronze ball valves have a ball bore diameter equal to the internal diameter of the pipeline, providing near-unrestricted flow and making them suitable for applications with high flow requirements.

Standard-bore ball valves have a smaller bore diameter than the pipeline, resulting in reduced flow capacity but a more compact structure, which is advantageous where installation space is limited.

Bronze is a time-honored metal alloy primarily composed of copper and tin, with optional additions of elements such as phosphorus, lead, or aluminum. Bronze exhibits the following notable characteristics:

Bronze demonstrates excellent corrosion resistance in seawater, freshwater, and many chemical media. This makes bronze ball valves particularly suitable for marine environments, chemical systems, and water treatment applications. For example, in desalination plants, ships, and offshore drilling platforms, bronze ball valves can withstand long-term exposure to seawater corrosion and ensure stable equipment operation.

Bronze offers relatively high strength and good ductility, allowing it to withstand significant pressure and impact loads. As a result, bronze ball valves can operate reliably under high-pressure conditions and provide a long service life. Even after extended use, bronze valves can effectively resist chemical corrosion and maintain good sealing performance.

Bronze materials are relatively easy to obtain and economical to process. Compared with some high-performance stainless steels or specialty alloys, bronze ball valves offer a clear price advantage. This makes them a cost-effective solution in many applications, especially in cost-sensitive projects.

Selecting a suitable bronze ball valve requires comprehensive consideration of multiple factors to ensure it meets actual operating requirements.

- Operating Pressure and Temperature: Identifying the maximum operating pressure and temperature is the first step in selecting a bronze ball valve. Different applications impose different pressure and temperature demands. For example, chemical systems may involve higher pressures and temperatures, while domestic water supply systems typically operate under lower conditions. The rated parameters of the selected valve must meet or exceed actual service requirements.

- Connection Type: Choosing an appropriate connection method is essential. Common connection types include threaded, welded (brazed), and flanged connections. Threaded connections are suitable for small-diameter pipelines and offer easy installation, though sealing performance may be relatively limited. Welded connections provide excellent sealing but require more complex installation and higher welding quality. Flanged connections are commonly used for larger pipelines, offering convenient installation and removal with reliable sealing. Compatibility with the existing piping system must also be ensured.

- Bore Type: The choice between full-bore and standard-bore valves should be based on required flow capacity. For applications with high flow demands, such as large industrial pipelines, full-bore bronze ball valves are recommended to minimize energy loss. For applications with lower flow requirements, standard-bore valves provide an economical alternative.

- Actuation Method: Depending on operation and control requirements, an appropriate actuation method should be selected, such as manual handles or pneumatic and electric actuators. Manual operation is suitable for applications with infrequent switching and offers simplicity and low cost. Pneumatic and electric actuators are ideal for remote or automated control systems, enabling fast and precise operation and improving automation levels.

- Sealing Performance: Stem sealing is critical for preventing external leakage. When selecting a bronze ball valve, attention should be paid to whether PTFE (polytetrafluoroethylene) seals or other packing materials suitable for the specific medium and operating conditions are used. Good sealing performance is essential for system safety and reliability.

- Surface Treatment and Special Material Configurations: Although bronze itself has good corrosion resistance, additional surface treatments or special material configurations may be required in highly corrosive environments, such as strong acids, strong alkalis, or high-chloride conditions. Options include protective coatings or bronze alloys with special alloying elements tailored to specific service requirements.

- Certifications and Standards: To ensure quality and reliability, bronze ball valves are typically designed and manufactured in accordance with relevant standards and certifications. These may include ANSI and ASME valve standards in the United States, API standards for oil and gas applications, and ISO certifications indicating compliance with international quality management systems. Depending on regional or industry requirements, compliance with environmental regulations such as RoHS or REACH may also be required.

Thanks to their flexibility and ease of operation, bronze ball valves are widely used in both industrial and civil applications.

Bronze ball valves perform exceptionally well in marine environments and are widely used in desalination plants, commercial vessels, naval ships, submarines, and offshore drilling platforms. These installations operate long-term in highly corrosive seawater environments, where bronze ball valves effectively resist corrosion and ensure reliable operation. Typical applications include ballast water systems, cooling systems, and seawater injection systems.

In chemical and water treatment systems, the corrosion resistance and reliable sealing performance of bronze ball valves make them an ideal choice. The antimicrobial properties of bronze also make these valves particularly suitable for potable water systems. They are widely used to control various chemical media in industrial pipelines and to regulate water flow in treatment plants.

Bronze ball valves are commonly used in fire protection systems. Their corrosion resistance and dependable sealing performance ensure that fire suppression systems function properly during emergencies, providing a reliable water supply for firefighting operations.

Bronze ball valves are widely used in domestic water supply and drainage systems. Their cost-effectiveness and reliability make them an ideal choice for residential and commercial buildings, where they help ensure stable and safe water distribution.

- Comparison with Brass Valves: Both brass and bronze valves are commonly used, but they differ in performance and application scope. Brass valves offer excellent corrosion resistance in potable water, HVAC systems, air, hydrogen, gas, and many other media. Forged brass provides a dense structure and good sealing performance. By contrast, bronze valves, with their higher tin content, may tolerate slightly higher temperature peaks under extreme conditions. Bronze valves are generally heavier and offer stronger impact resistance, though they require more effort during installation and handling. Brass valves are lighter and easier to install and maintain.

- Comparison with Stainless Steel Valves: Stainless steel valves offer higher strength and broader corrosion resistance across a wider range of media and operating conditions. However, they are more expensive, and in certain chemical environments, such as those with high chloride content, the corrosion resistance of bronze may outperform stainless steel. Additionally, bronze valves have lower processing costs and offer superior cost-effectiveness in many applications.

To ensure long-term stable operation, regular maintenance and care of bronze ball valves are essential.

- Regular Inspection: Periodically inspect the valve’s external condition and sealing performance to identify potential issues early. Check for leakage, ensure smooth stem movement, and verify that handles or actuators operate correctly. Any problems should be addressed promptly through repair or replacement.

- Cleaning and Lubrication: Regularly clean the valve surface to remove dust and contaminants and prevent corrosion. Lubricate the valve stem and actuator as required to ensure smooth operation, using appropriate lubricants that do not contain corrosive components.

- Avoid Over-Operation: Avoid excessive force or frequent operation, which can damage seals and internal components. Operate the valve in accordance with manufacturer instructions to maximize service life.

With their excellent corrosion resistance, good strength and durability, and high cost-effectiveness, bronze ball valves are widely used in both industrial and civil applications. When selecting a bronze ball valve, factors such as operating pressure and temperature, connection type, bore configuration, actuation method, sealing performance, surface treatment, special material options, and applicable certifications and standards must all be carefully considered. With proper selection, maintenance, and care, bronze ball valves can provide long-term, reliable flow control solutions for a wide range of systems.