This article compares two primary types of safety valves, spring-loaded and lever-operated, used in pressure vessels and piping systems. Safety valves are essential for preventing hazardous conditions caused by excessive pressure. The spring-loaded safety valve operates by using the elastic force of a spring to open the valve when pressure exceeds a preset value, offering compact design and flexibility for installations in tight spaces. However, it is sensitive to high temperatures and may experience fatigue over time. In contrast, lever-operated safety valves use a lever and weight mechanism to balance the pressure and open the valve, making them ideal for high-temperature and high-pressure environments. They offer long-term stability but require more space and can be sensitive to vibrations.

Safety valves are critical devices used in pressure vessels and piping systems to prevent hazardous conditions caused by excessive pressure. Depending on their working principles and structural design, safety valves can be classified into spring-loaded safety valves and lever-operated safety valves. Each of these types has its unique advantages and disadvantages, making them suitable for different operating environments and requirements. This article provides a detailed comparison of the working principles, advantages, disadvantages, and applications of both types of safety valves to help in selecting the appropriate valve for specific needs.

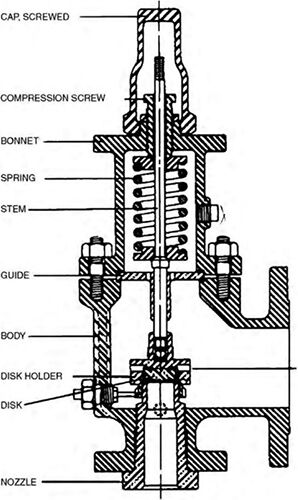

Working Principle The spring-loaded safety valve operates based on the elastic pressure of a spring. It contains a spring within its structure, and when the pressure of the medium exceeds a preset value, the pressure overcomes the spring's resistance, causing the valve disc to open and release the excess pressure. The opening pressure of the valve can be precisely set by adjusting the compression of the spring.

Structural Features Spring-loaded safety valves have a compact design and small size, making them suitable for installation in spaces where space is limited. The compression of the spring can be adjusted by turning a regulating nut, allowing precise control over the valve's opening pressure. Additionally, these valves are less sensitive to vibrations, which makes them ideal for use in mobile pressure vessels.

Compact Structure: Compared to lever-operated safety valves, spring-loaded safety valves have a smaller and more sophisticated design, making them suitable for space-constrained applications.

Flexible Installation: The installation position is not strictly restricted, allowing use in tight spaces.

High Responsiveness: These valves have high sensitivity and can respond quickly to pressure changes.

Wide Applicability: Suitable for both liquid and gas media, they perform excellently in environments with low temperature or minimal pressure fluctuations.

Temperature Sensitivity: In high-temperature environments, the spring's elasticity can degrade, leading to a reduction in the opening pressure over time. Therefore, they are not suitable for long-term use in high-temperature settings.

Opening Stability: As the valve disc rises, the compression of the spring increases, which can affect the quick opening of the valve.

Fatigue Over Time: Prolonged exposure to heat can cause the spring to lose its elasticity, resulting in inaccurate pressure settings.

Spring-loaded safety valves are ideal for applications with stable pressure and temperature conditions, especially in pressure vessels, storage tanks, and systems involving liquid or gas media. Their compact design also makes them suitable for installation in equipment with limited space, including mobile equipment.

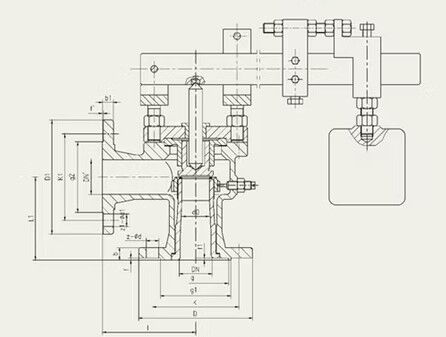

Working Principle Lever-operated safety valves use the force of a lever and weight to balance the pressure acting on the valve disc. When the pressure of the medium exceeds the set value, the weight moves the valve disc open through the lever mechanism. The opening pressure can be precisely adjusted by changing the weight or position of the weight.

Structural Features Lever-operated safety valves have a more complex structure, typically consisting of a lever, weight, and valve body. Installation requires careful alignment to ensure that the valve disc's axis is perpendicular to the horizontal plane. These valves are particularly well-suited for high-temperature and high-pressure environments, such as boilers and high-temperature pressure vessels.

Suitable for High-Temperature Environments: Unlike spring-loaded safety valves, the opening pressure of lever-operated safety valves is not affected by high temperatures, making them stable and reliable in high-temperature settings.

Easy Adjustment: The opening pressure can be precisely adjusted by altering the weight's position or changing the weight itself.

Long-Term Stability: In high-temperature environments, lever-operated safety valves maintain their opening pressure over time, providing high stability.

Large Size: Lever-operated safety valves are larger in size compared to spring-loaded valves and require more space for installation, along with careful alignment.

Vibration Sensitivity: The lever and weight structure is more susceptible to vibrations, which could potentially cause leaks or inadequate sealing.

Low Re-seat Pressure: These valves tend to have low re-seat pressure, making it difficult for the valve to fully close once opened, which may prevent a complete seal.

Lever-operated safety valves are widely used in boilers and high-temperature pressure vessels, where they are required to operate in high-temperature environments. These valves are ideal for relieving pressure in high-temperature media and maintaining stable opening pressure over extended periods.

The spring-loaded safety valve and lever-type safety valve each have distinct characteristics and suitable applications.

Spring-Loaded Safety Valves: Compact, simple, and suitable for space-constrained environments.

Lever-Operated Safety Valves: Larger and require strict installation to ensure the proper balance of the lever mechanism.

Spring-Loaded Safety Valves: Their performance can be affected by high temperatures, with the opening pressure gradually decreasing.

Lever-Operated Safety Valves: Perform stably in high-temperature environments and maintain consistent opening pressure.

Spring-Loaded Safety Valves: Opening pressure is adjusted by modifying the spring's compression, offering high precision.

Lever-Operated Safety Valves: Opening pressure is adjusted by moving or changing the weight, providing precise control.

Spring-Loaded Safety Valves: Suitable for both liquid and gas media, especially in more compact, lightweight equipment.

Lever-Operated Safety Valves: Best suited for high-temperature and high-pressure environments, commonly found in boilers and pressure vessels.

Choosing the appropriate safety valve type depends on the specific application requirements. Spring-loaded safety valves are ideal for equipment with stable temperature and pressure conditions, offering a compact design and quick response, especially in liquid and gas media applications. On the other hand, lever-operated safety valves are more suitable for long-term use in high-temperature and high-pressure environments, particularly in boilers and other high-temperature pressure vessels. Therefore, the decision to use a spring-loaded or lever-operated safety valve should take into account factors such as the type of media, working temperature, installation space, and the precision required for opening pressure. Selecting the right valve ensures the safe and stable operation of equipment, preventing safety risks caused by improper valve selection.