In industrial production, steam systems play an extremely critical role, and steam traps, as important components within these systems, have their installation directly related to the operational efficiency and safety of the entire system. Today, let's dive deeply into the topic of steam trap installation, helping everyone better understand and master the correct installation methods for steam traps.

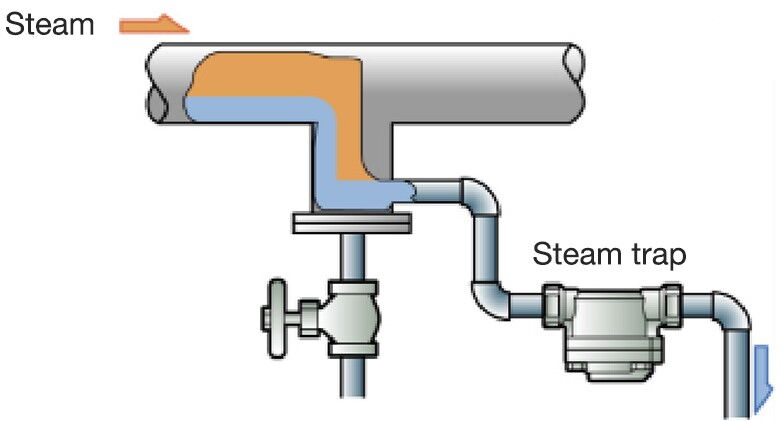

The inlet pipe of a steam trap is an extension of the main steam line. From the perspective of reducing heat radiation loss, installing the steam trap close to the main line seems like a good choice. However, the actual situation is not that simple. Main steam lines are usually installed at higher positions. If the steam trap is installed right next to the main line, it will bring great inconvenience to daily maintenance and inspection work. These remotely installed steam traps are easily overlooked and forgotten, and in the event of a failure, they may not be repaired for years, thereby affecting the normal operation of the entire steam system.

If ladders or other facilities that allow convenient access to high positions are near the steam trap installation location, the situation can improve. But if there are no such auxiliary facilities, we strongly recommend installing the steam trap in a location that is easy to access. This ensures that when maintenance or inspection is required, personnel can easily reach the steam trap, promptly detect and resolve problems, and ensure the stable operation of the steam system.

Additionally, when the steam trap is installed horizontally, it is recommended that the pipe connecting it to the condensate collection point be as short as possible. The purpose of this is to reduce heat radiation loss and improve the energy utilization efficiency of the steam system. When using a condensate collection point to collect condensate from elevated steam pipelines, if there are spatial layout constraints, a pipe can be connected directly from the collection point to a steam trap. Regardless of vertical or horizontal installation, the required configuration is the same; for example, isolation valves must be installed before and after the steam trap, and a bypass line should be set. Therefore, installing a steam trap near the ground implies occupying a larger area.

After discussing the key factors in choosing the installation location, let's further explore the selection of the installation method. Choosing the installation method is equally critical, as it not only affects the operational efficiency of the steam trap but also directly impacts subsequent maintenance and repair work. Different installation methods have their respective advantages and disadvantages, so in practical applications, we need to make a reasonable choice based on specific site conditions and requirements.

When installing a steam trap vertically, sufficient support, such as a pipe rack, is required to support the trap and other pipelines. This is because vertically installed steam traps are relatively heavy, and without firm support, the pipe may deform or the trap may be damaged. Moreover, if the trap is not securely fixed to the ground, maintenance and repair work will become extremely difficult. Therefore, vertical supports should be set up and fixed to the ground to ensure the stability and safety of the trap.

When the steam trap is installed close to the ground, no additional supports are needed, as the ground can provide sufficient support. The advantage of this installation method is that the steam trap is easier to reach, making maintenance and repair relatively convenient. Moreover, condensate can drain more smoothly during operation, reducing accumulation inside the pipeline, thereby lowering heat radiation loss and improving the energy utilization efficiency of the steam system.

Each installation method has its own advantages and disadvantages. Therefore, when choosing the installation method, it is necessary to consider the actual site conditions comprehensively. For example, if the site space is limited and the steam main line is relatively high, vertical installation may be a better choice; if the site has sufficient space and requires convenient maintenance and inspection, horizontal installation may be more suitable.

When selecting a steam trap for the main steam line, it is strongly recommended to use traps with continuous drainage characteristics, such as free float traps. Free float steam traps can continuously discharge condensate, ensuring that the steam main line remains dry and thereby improving the efficiency and safety of the steam system. If the condensate collection point is appropriately sized and condensate does not accumulate in the main line, other types of traps can also be used, such as disc traps, inverted bucket traps, or pressure-balanced thermostatic traps.

However, bimetallic steam traps are not recommended for main lines. This type of trap is likely to cause condensate accumulation inside the main line, especially when installed close to the pipeline. Condensate accumulation in the main line not only reduces steam temperature and pressure but can also cause pipe corrosion and damage, seriously affecting the service life and operational efficiency of the steam system.

The limitations on the installation direction of steam traps are closely related to the trap's structure and operating principle. Mechanical steam traps, such as bucket and float types, operate based on the buoyancy and gravity acting on the float. Therefore, their installation direction is strictly limited. If such traps are installed incorrectly, buoyancy and gravity cannot achieve the proper balance, and the valve loses its intended function, meaning the trap cannot operate normally.

Types whose operation is not affected by gravity, such as traps that operate based on the phase change of steam to water or those relying on the shape change of their components, are relatively unconstrained. However, even for traps whose mechanical structure is gravity-independent, the installation direction may still affect operation.

For example, many thermostatic and disc traps can be used on both vertical and horizontal pipelines. Disc traps, in particular, can be installed on vertical or horizontal pipes without problems. However, even when installed on horizontal pipes, the trap should not be inverted. Depending on the installation orientation, the condensate inside the trap may not be horizontal. This type of trap operates based on temperature differences, so uneven temperatures in the sensing element can adversely affect performance.

Thermosensitive liquid and bimetallic traps follow the same principle for installation orientation. When installed on horizontal pipes, the X element is positioned higher than the pipe, so condensate fills the pipe and trap before reaching the X element, causing intermittent operation. When installed on vertical pipes, the X element is in continuous contact with condensate, with the lower part always submerged and the upper part always in steam. Thus, the X element operates at an "average temperature," making intermittent operation difficult and resulting in unstable operation.

Before installing steam traps, there are several important details to pay attention to:

- Cleaning the Pipeline Equipment: The pipeline equipment must be cleaned before installation to remove impurities and avoid blockages. During operation, the steam system may generate impurities and debris, which can clog the trap and affect its normal function.

- Choosing the Installation Location: Steam traps should be installed in easily maintainable locations and, if possible, arranged in a centralized manner for easier management. This allows personnel to quickly locate the traps for maintenance and inspection. Each heating device should have its own steam trap to ensure effective control of steam supply and avoid interference between devices.

- Bypass Pipe Installation: The bypass pipe must not be installed lower than the steam trap. The purpose of the bypass pipe is to ensure normal operation of the steam system during trap failure or maintenance. If installed too low, condensate may not drain smoothly, affecting system efficiency.

- Pay Attention to Arrow Direction: During installation, ensure that the arrow on the trap body aligns with the flow direction of the medium. This is a key factor to ensure the trap works properly. If the arrow is opposite the medium flow, the trap cannot discharge condensate correctly and may even be damaged.

- Pipeline Slope and Diameter: The inlet and outlet pipes of the steam trap should have a 5–10% downward slope in the flow direction. This helps condensate drain smoothly, reducing accumulation. The nominal pipe diameter should not be smaller than the trap's nominal diameter to ensure it can handle the required steam and condensate flow.

- Parallel Installation and Freeze Protection: If one steam trap's drainage capacity cannot meet the requirement, multiple traps can be installed in parallel to increase system drainage capacity and ensure normal operation. Additionally, for areas prone to freezing, protective measures must be taken. For example, in cold regions or winter, insulation or electric heat tracing can be applied around the trap to prevent condensate from freezing and affecting system operation.

Installing steam traps for main steam lines involves more than just selecting the right model. Installation space, location, and other factors affect pipeline layout and the smooth operation of the system. Therefore, we strongly recommend carefully examining the factory's actual conditions before purchasing steam traps, determining the installation method first, and then selecting the appropriate trap.

Only in this way can steam be efficiently delivered to the point of use while balancing energy loss and maintenance costs, ensuring long-term stable operation of the steam system.

In short, correctly installing steam traps is crucial for improving the efficiency and safety of steam systems. By properly choosing the installation location and method, and paying attention to installation details, we can ensure that steam traps operate normally, reduce energy waste, lower maintenance costs, and bring greater economic benefits to enterprises. We hope this article will be helpful, enabling everyone to install steam traps more effectively and confidently.