73-84 of 142 results for "Industry News"

Eccentric Plug Valve: A High-Performance Fluid Solution

Industry News

Oct 30, 2025

5

In the field of industrial fluid control, valves, as key equipment components, have performance and reliability that directly affect the stable operation of the entire system. As a new type of valve design, the eccentric plug valve, with its unique structure and excellent performance, is...

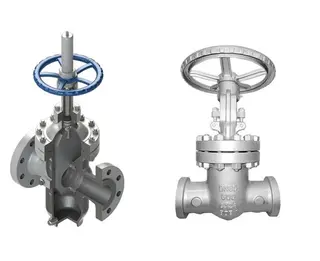

Comparison Between Wedge Gate Valves and Slab Gate Valves

Industry News

Oct 29, 2025

12

As one of the most commonly used shut-off valves in industrial pipeline systems, gate valves come in diverse structural forms. Different types of gate valves have their own advantages in sealing methods, operational characteristics, and applicable working conditions. Among many designs, wedge...

How to Choose the Right Butterfly Valves?

Industry News

Oct 28, 2025

15

In the industrial field, valves are indispensable components of piping systems. They control the flow of fluids and ensure the smoothness and safety of process operations. As a common type of valve, butterfly valves are widely used in various industrial settings due to their unique structure and...

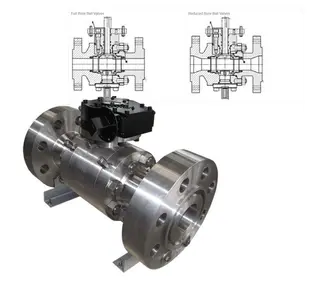

Full Bore Ball Valves vs. Reduced Bore Ball Valves

Industry News

Oct 27, 2025

19

In industrial piping systems, ball valves, as a common type of valve, are widely used in various fluid control scenarios. Ball valves are highly favored by engineers and operators due to their simple structure, ease of operation, and excellent sealing performance. However, ball valves are not...

Maintenance Guide for Steam Trap Failures

Industry News

Oct 24, 2025

20

In industrial production, steam traps play a crucial role. They can effectively "block steam and discharge condensate," ensuring the steam system operates efficiently and safely. However, during use, steam traps inevitably experience various failures, which not only affect the normal operation of...

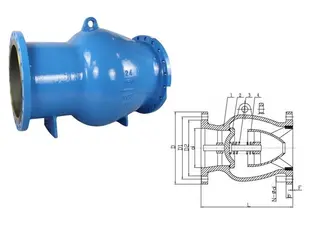

Axial Flow Check Valve: The Guardian of Industrial Pipelines

Industry News

Oct 23, 2025

22

In modern industrial production, pipeline systems play a crucial role. They are like the blood vessels of the human body, responsible for transporting various media, from liquids to gases, from oil to water. However, just as blood vessels need to prevent the backflow of blood, pipeline systems...

V-Port Ball Valve: Efficient Regulator in Industrial Control

Industry News

Oct 22, 2025

9

In industrial production, valves are critical components of fluid control systems, and their importance is self-evident. As a special type of ball valve, V-Port Ball Valves stand out among various valve types due to their unique design and excellent performance, becoming an important choice in...

How to Choose the Appropriate Check Valves?

Industry News

Oct 21, 2025

15

In industrial production, check valves are indispensable equipment that can effectively prevent backflow of the medium, protecting the safety and operation of piping systems and equipment. However, faced with a wide variety of check valves, how to correctly select the appropriate model and...

API 608 vs. API 6D Ball Valves: Design, Function & Application

Industry News

Oct 20, 2025

4

In industrial pipeline systems, ball valves, as a key control component, are of undeniable importance. Ball valves come in many types, among which API 608 ball valves and API 6D ball valves are the most common and widely used. They have significant differences in structural design, functional...

Needle Valves: Precision Regulators in Industrial Control

Industry News

Oct 17, 2025

22

In the complex networks of modern industry, valves play a crucial role, precisely controlling the direction, pressure, and flow of fluids. From petroleum refining to chemical production, from pharmaceutical processes to food processing, valves are ubiquitous. Among the many types of valves,...

Weir Diaphragm Valves vs. Straight-Through Diaphragm Valves

Industry News

Oct 16, 2025

12

In the industrial field, diaphragm valves, as an important control element, are widely used in various fluid control occasions. Diaphragm valves, with their unique structure and performance advantages, play a key role in industries such as chemical, pharmaceutical, food, and water treatment....

How to Choose the Right Plug Valves?

Industry News

Oct 15, 2025

11

In the industrial field, valves are key devices for controlling fluid flow. As a long-established and widely used type of valve, plug valves play an important role in many industrial scenarios due to their unique structure and performance characteristics. A plug valve is a valve that controls...

Total 142 Records, 12 records per page