Safety valves are critical components in industrial facilities, ensuring the safe operation of pressure vessels, boilers, and other equipment by releasing excess pressure to prevent accidents. Proper installation is essential for their functionality and long-term performance. Key installation aspects include selecting the correct location, ensuring proper discharge outlet layout, and maintaining appropriate piping design. Special attention is required for handling specific media, such as toxic or flammable substances, and ensuring valves remain free of obstructions. Additionally, safety valves should be installed at the highest points of vessels, with preventive measures against misoperation and regular inspections to maintain reliability. Following installation standards and regularly maintaining safety valves ensures their effectiveness, safeguarding personnel and equipment from overpressure-related risks.

Safety valves play a crucial role in industrial facilities, particularly in pressure vessels, boilers, and other equipment. They are responsible for automatically releasing gases or liquids when the pressure exceeds safe limits, ensuring the safety of both equipment and personnel. To guarantee the functionality and long-term stable operation of safety valves, strict technical requirements and standards must be followed during installation. Below are several key aspects that require special attention during the installation of safety valves.

The installation location of a safety valve is critical to its functionality. When a container contains both gas and liquid phases, the safety valve should be installed in the gas phase section. This ensures that the safety valve can operate promptly in the event of abnormal gas pressure increases, without being affected by the liquid. Especially in liquefied gas storage tanks, the safety valve must be located in the gas phase section to ensure proper pressure release.

During the discharge of flammable liquids, the outlet of the safety valve should be directly connected to an emergency storage tank. For the discharge of high-temperature flammable substances, the receiving container must be equipped with appropriate protective measures to mitigate the risk of fire or explosion.

The discharge outlet of the safety valve must be carefully designed to avoid pointing toward adjacent equipment or areas frequently accessed by personnel. The discharge outlet should be installed at least 3 meters above a platform or building and should be higher than any platform or building within an 8-meter radius. This design helps prevent harm to the surrounding environment and ensures the safety of personnel and equipment.

The discharge pipe should avoid sharp bends or excessive curvature to minimize resistance during discharge. The pipe should lead directly to a safe location, and its cross-sectional area should be sufficiently large to allow smooth discharge of gases or liquids. Additionally, safety valves should not share discharge pipes for substances that may undergo chemical reactions. For corrosive or flammable gases, the discharge pipe should be equipped with anti-corrosion and explosion-proof measures. For toxic media, especially gases with a vapor density greater than air, the discharge pipe should be connected to a closed system to prevent environmental contamination.

The cross-sectional area of the piping and fittings connected to the safety valve should not be smaller than the inlet cross-sectional area of the safety valve. If multiple safety valves share a common inlet pipe, the cross-sectional area of the inlet pipe should be greater than or equal to the sum of the inlet areas of all safety valves. The connecting pipe between a boiler and a pressure vessel should avoid the installation of shut-off valves or other branch pipes to ensure that the safety valve can release pressure without restriction when needed.

For safety valves equipped with isolation valves, the valve should remain in the normally open position and be sealed to prevent accidental operation. Any factors that could hinder the normal operation of the safety valve should be eliminated, such as piping structures that could impede pressure release.

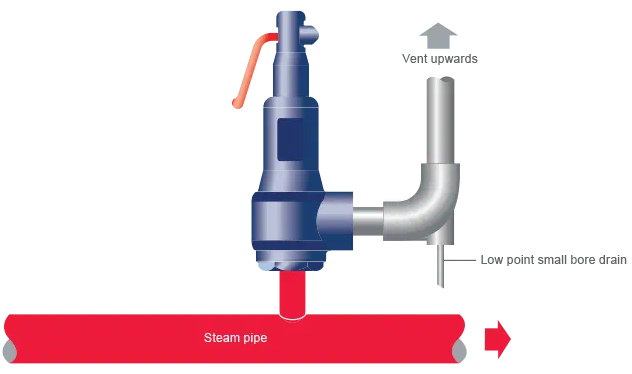

Safety valves must be equipped with discharge pipes, and the pipes should avoid sharp bends or excessive curvature to reduce resistance and ensure smooth discharge. All discharge pipes must be securely fixed to prevent additional stress or vibration that could affect the safety valve's functionality. For safety valves installed outdoors, anti-freezing measures should be considered to prevent the medium inside the valve from freezing at temperatures below 0°C, which could impair its operation. For media with a crystallization temperature higher than the lowest ambient temperature, insulation jackets and steam purging devices should be installed to prevent crystallization and clogging of the safety valve.

Additionally, the inlet and outlet pipes of the safety valve should be designed with steam-traced jackets or insulation to ensure that the pipes and safety valve remain unobstructed by crystallized media.

When handling special media, additional factors must be considered during the installation of safety valves. For example, when dealing with toxic or flammable media, shut-off valves should not be installed between the safety valve and the pressure vessel unless approved by technical supervisors and accompanied by strict protective measures. Particularly for pressure vessels containing highly toxic or highly hazardous media, the technical personnel of the operating unit must review and approve the connecting piping between the safety valve and the pressure vessel.

For shut-off valves that must remain fully open during normal operation, they should be sealed or locked to prevent accidental operation. The design and size of the shut-off valve should not impede the normal pressure release function of the safety valve.

The connection between the safety valve and the boiler or pressure vessel must comply with specific design standards. For boilers with a rated steam pressure of 3.82 MPa or less, the throat diameter of the safety valve should not be less than 25 mm; for boilers with steam pressure greater than 3.82 MPa, the throat diameter should not be less than 20 mm. Additionally, safety valves for boilers and pressure vessels should ideally be installed directly at the highest point of the vessel to ensure timely response to pressure changes.

For boilers with a rated evaporation capacity greater than 0.5 t/h, at least two safety valves should be installed; for boilers with a rated evaporation capacity of 0.5 t/h or less, at least one safety valve is required. Safety valves must also be installed at the economizer outlet and superheater outlet to ensure the safety of the entire system.

The design of safety valves should include devices to prevent the weight from moving on its own and guide frames to limit lever movement. Additionally, spring-loaded safety valves should be equipped with lifting handles and devices to prevent unauthorized adjustment of the screws, ensuring that no misoperation occurs during installation and adjustment.

No steam extraction pipes or valves should be installed between the safety valve and the boiler drum or header, as this could affect the safety valve's normal pressure release function. Safety valves should be installed vertically at the highest point of boilers, headers, or other equipment to ensure they can promptly release pressure when it exceeds safe limits.

Regular maintenance and inspection of safety valves are essential to ensure their long-term stable operation. All safety valves should be ready for use immediately after installation and should undergo periodic inspections during operation. Any potential blockages should be cleared promptly to prevent pressure release failure due to crystallization, clogging, or damage. For safety valves in use, the cleanliness of all related equipment and piping must be maintained to avoid affecting their normal operation.

The installation and use of safety valves must strictly adhere to relevant standards and regulations to ensure that equipment can effectively release pressure in the event of overpressure, preventing serious accidents such as equipment damage, explosions, or fires. Through proper design, installation, and regular inspection, safety valves can maintain optimal performance throughout the equipment's lifecycle, safeguarding both personnel and equipment.