Gate valves are vital components in industrial piping systems, used for controlling fluid flow. This article compares two main types of gate valves, rising stem and non-rising stem, highlighting their structural differences, advantages, disadvantages, and appropriate applications. Rising stem gate valves, with visible stem movement, are ideal for low-pressure, small-flow systems that require frequent visual inspection and simple maintenance. In contrast, non-rising stem gate valves feature a compact design, making them more suitable for confined spaces and high-pressure, high-flow applications. They offer better resistance to environmental contamination and are well-suited for automated systems. The article concludes by providing guidance on choosing the appropriate valve based on factors like installation space, medium characteristics, and operational requirements.

Gate valves are widely used in industrial piping systems as essential devices for controlling the flow of fluids. Based on the design and structure of the valve stem, gate valves can be categorized into rising stem and non-rising stem gate valves. These two types of gate valves differ significantly in terms of structure, operation, installation space requirements, and ease of maintenance. This article provides a detailed comparison of the structural features, advantages, disadvantages, and suitable applications of these two valve types, helping readers choose the most appropriate gate valve for their specific needs.

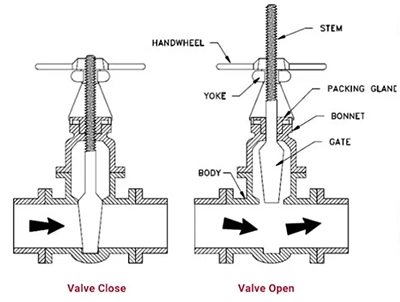

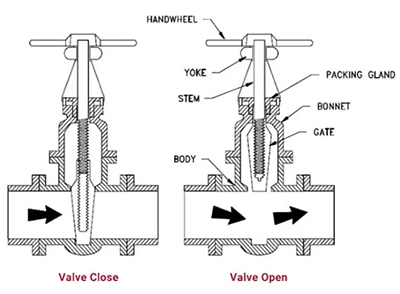

The rising stem gate valve features a valve stem with a nut located on the valve bonnet or bracket. The stem moves up and down through the rotation of the nut. When the handwheel is rotated, the nut drives the stem to move vertically, thus operating the gate to open or close. The stem thread is exposed on the outside of the valve, making it visible during operation, so the operator can easily observe the valve's open or closed state.

In a rising stem gate valve, the stem is typically connected to the gate via a T-head, and the rotation of the stem moves the gate up and down. The stem is connected to the handwheel, and through a threaded mechanism, the gate is opened or closed. Since the stem thread is on the outside, when the stem rotates, it moves axially, causing the gate to open or close.

Visual Operation: The exposed stem allows operators to directly observe the vertical movement of the stem, which helps in visually determining the valve's open or closed status.

Easy Maintenance: The exposed stem thread makes it easy to inspect and clean the stem. Maintenance is simpler because the entire valve does not need to be disassembled for repairs.

Lubrication Ease: Since the stem is visible, it is easier to lubricate and maintain, which helps extend the valve's service life.

Simple Structure: Compared to non-rising stem gate valves, rising stem gate valves have a simpler structure, which reduces manufacturing and maintenance costs.

Larger Space Requirement: Since the stem is exposed and moves vertically, rising stem gate valves require more space, and the stem's travel range must be considered during installation.

Environmental Impact: The exposed stem is susceptible to contamination from external environmental factors (such as dust or corrosive substances), which can decrease the valve's durability, especially in harsh working environments.

Not Ideal for High-Pressure Applications: Rising stem gate valves may not be as stable as non-rising stem valves in high-pressure environments, as the vertical movement of the stem could potentially affect the valve's sealing performance.

Rising stem gate valves are typically used in low-pressure, small-flow piping systems and are especially suitable for applications that require frequent operation and visual inspection of the valve's position. They perform well in systems that involve manual operation, such as fire protection systems or low-pressure pipelines.

In a non-rising stem gate valve, the stem nut is located inside the valve body, and the stem moves the gate vertically through rotation. As the stem thread is located within the valve body, operators cannot directly observe the stem's movement. The stem is usually in direct contact with the medium, so non-rising stem gate valves require higher standards for the medium. The entire opening and closing process is achieved by rotating the stem to move the gate, without any vertical movement of the stem.

In a non-rising stem gate valve, the stem thread is housed within the valve body, and the stem is rotated via a handwheel or an electric/pneumatic actuator. The rotating stem moves the gate up and down to open or close the valve. Since the stem does not move vertically, there is no visible change in the appearance of the valve, and it is difficult to assess the valve's open or closed status just by observing the stem. Typically, an external indicator is used to help determine the valve's position.

Space-Saving: Non-rising stem gate valves have a more compact design since the stem does not require vertical movement. They are suitable for installation in spaces with limited room.

Resistance to Environmental Contamination: The stem thread is protected inside the valve body, making it less vulnerable to external contaminants (such as dust or corrosive substances), enhancing the valve's durability. This makes non-rising stem valves ideal for harsh environments.

Suitable for High-Flow, High-Pressure Applications: Non-rising stem gate valves are commonly used in high-pressure and high-flow systems due to their superior sealing performance and pressure resistance, making them suitable for high-pressure pipelines.

Non-Visual Operation: Since the stem is not visible, operators cannot directly observe the valve's status. An external position indicator is typically required to monitor the open or closed state of the valve.

More Complex Maintenance: The internal stem threads require disassembling the valve for maintenance, making repairs more complex compared to rising stem valves.

Stringent Medium Requirements: Since the stem comes into direct contact with the medium, non-rising stem valves are not ideal for handling fluids with impurities, as the particles could damage the stem and gate threads, affecting valve operation.

Non-rising stem gate valves are widely used in confined spaces or applications requiring automated control, particularly in high-flow, high-pressure pipeline systems. They are also common in systems that require remote or automated operation, such as oil and gas pipelines and chemical processing equipment. Due to their compact design, non-rising stem valves are ideal for installations with space constraints.

When selecting between a rising stem and a non-rising stem gate valve, several factors should be considered.

Installation Space: Rising stem valves require more installation space due to the vertical movement of the stem, especially in high-pressure or large-diameter pipelines. Non-rising stem valves, with their compact design, are better suited for environments with limited space.

Operation and Maintenance: Rising stem valves allow for visual monitoring of the valve position, making them more suitable for applications requiring frequent operation and inspection. Non-rising stem valves, with their sealed design, are more suited for automated systems that do not require regular manual inspection, although they may be more complex to maintain.

Environment and Medium: Rising stem valves are exposed to environmental contaminants, which can affect their performance in harsh conditions. Non-rising stem valves, with their internal stem threads, are more resistant to such contaminants, making them more appropriate for environments with high corrosion or pollution.

Performance and Durability: Rising stem valves are ideal for small-flow, low-pressure systems where ease of operation and maintenance are prioritized. Non-rising stem valves are more suitable for large-flow, high-pressure applications that require superior sealing and pressure resistance.

Both rising stem and non-rising stem gate valves have distinct advantages and applications. Rising stem gate valves, with their simple structure, easy operation, and convenient maintenance, are well-suited for small-flow, low-pressure applications. On the other hand, non-rising stem gate valves, due to their compact design, environmental resistance, and ability to handle high-pressure and high-flow systems, are commonly used in automated control systems and large-scale pipelines. When selecting a gate valve, it is crucial to consider factors such as installation space, operational requirements, medium characteristics, and maintenance needs to choose the appropriate type for the specific application.