Diaphragm valves are specialized shut-off valves widely used for fluid isolation, regulation, and control in industries requiring high hygiene and safety standards. The valve's unique design features an elastic diaphragm, which moves to open or close the fluid passage, ensuring precise flow control. Key advantages include simple structure, easy maintenance, fluid isolation, contamination prevention, and suitability for handling corrosive, viscous, or particulate-laden fluids. Diaphragm valves are commonly used in food, pharmaceutical, chemical, and power industries. Fluorine-lined versions offer enhanced chemical resistance for demanding applications. However, diaphragm valves are best suited for low-pressure and low-temperature environments, with regular maintenance required to ensure reliable operation.

A diaphragm valve is a specialized type of shut-off valve with a unique design and operating principle. It is widely used in applications where fluid isolation, flow control, or regulation is required. The valve's closing component consists of a diaphragm made from soft material, which separates the valve body from the valve bonnet, enabling fluid flow control and throttling adjustments. With its simple structure, ease of operation, low maintenance, and versatility in handling special working conditions, the diaphragm valve has become an indispensable component in modern industry.

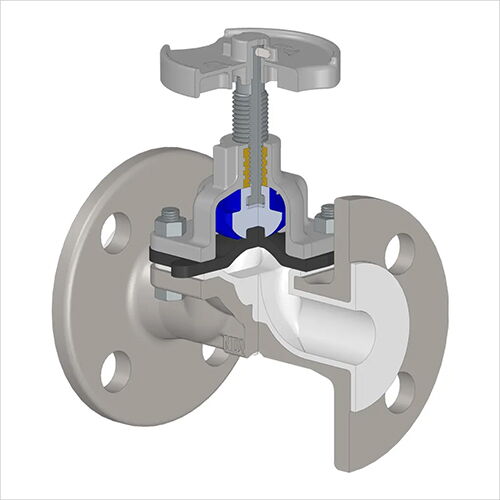

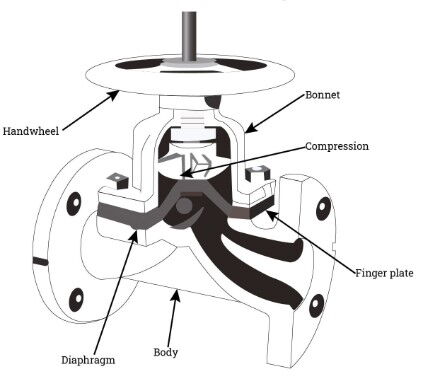

The diaphragm valve is primarily composed of three main parts: the valve body, diaphragm, and valve bonnet. Its operating principle differs from traditional shut-off valves by using an elastic diaphragm in place of the traditional valve disk. The diaphragm moves up and down via the valve stem, completing the opening and closing of the fluid passage and regulating flow. Specifically, when the valve stem rises, the diaphragm is lifted, opening the fluid passage. When the stem lowers, the diaphragm presses against the valve body seat or bottom, closing the fluid passage. This straightforward opening and closing mechanism makes the diaphragm valve particularly suitable for on-off operations and flow regulation.

Diaphragm valves, with their unique design and structure, offer several significant advantages in various industrial applications. Below are the main features and benefits of diaphragm valves.

Simple Structure and Easy Maintenance: The design of the diaphragm valve, consisting of just the valve body, diaphragm, and bonnet, is simple and easy to maintain. The diaphragm can be replaced on-site quickly, without the need for complex tools or equipment.

Isolation of Fluid and Actuating Mechanism: The diaphragm valve's actuating mechanism is completely isolated from the fluid flow path, making it especially advantageous when dealing with fluids that require specific handling. In industries such as food and pharmaceuticals, where hygiene is paramount, diaphragm valves effectively prevent contamination. Additionally, these valves are well-suited for handling challenging, hazardous, or highly corrosive fluids.

Contamination Prevention and Leak-free Design: The diaphragm design keeps the actuating mechanism separate from the fluid, reducing the risk of leakage from stem packing and minimizing contamination. This feature makes diaphragm valves widely used in food, pharmaceutical, and chemical industries.

Suitability for Various Fluids: The materials used for diaphragm valves can be selected based on specific applications, making them suitable for a range of corrosive, viscous, or particulate-laden fluids. With the use of synthetic rubber, engineering plastics, and fluorine-lined materials, diaphragm valves can be applied in a broader range of environments, especially when ultra-pure fluids or high cleanliness standards are required.

Low Pressure Loss and Excellent Fluid Control: The fluid passage design of diaphragm valves causes minimal pressure loss as the fluid flows through, with a nearly straight flow path that prevents turbulence. This design makes diaphragm valves ideal for applications requiring precise flow control, especially in on-off operations.

Diaphragm valves are widely used in any environment that requires fluid isolation, switching, or regulation. They are especially suitable for handling corrosive, viscous, or particulate-containing fluids. Common applications include:

Biopharmaceutical and Food Industries: Diaphragm valves are extensively used in food, pharmaceutical, and other industries where hygienic isolation of fluids is critical. Due to their simple construction and ease of cleaning, they are ideal for industries with high cleanliness and safety demands.

Chemical and Power Industries: In chemical and power industries, diaphragm valves are used for handling corrosive or particulate-laden fluids. Their design helps avoid leaks and contamination, maintaining process safety.

Water Treatment and Semiconductor Industries: Diaphragm valves are widely used in the water treatment industry, especially in industrial water treatment. They are also used in semiconductor wafer production, where reliability and high performance are crucial in these high-precision, demanding fields.

Fluorine-lined diaphragm valves, a specialized type of diaphragm valve, offer enhanced corrosion resistance and chemical stability. They are particularly suitable for transporting ultra-pure fluids, heavily contaminated, or viscous liquids. The fluorine lining material enables these valves to operate in more demanding environments over extended periods, making them ideal for industries such as chemicals, pharmaceuticals, and power generation. They are especially effective for handling solid particulates and easily contaminated fluids, providing better control precision and reliability compared to other traditional control systems.

Despite their many advantages, diaphragm valves have some limitations. Since their operation relies on the elastic deformation of the diaphragm, their use is restricted under high temperature and pressure conditions. The materials of the diaphragm and valve body determine the working temperature and pressure range, with typical operating temperatures not exceeding 180°C, a nominal pressure below 40 bar, and nominal diameters under 200 mm. Under high temperature and pressure, repeated diaphragm deformation may cause damage and lead to leaks. Therefore, diaphragm valves are primarily suitable for low-temperature and low-pressure environments and require regular inspection and diaphragm replacement.

As a specialized valve type, diaphragm valves have vast potential across various industrial applications. Their unique design enables them to play an essential role in industries where strict fluid control and cleanliness are necessary. With advances in materials technology and increasing demand for high-performance valves, diaphragm valves will continue to play an important role in industries such as food, pharmaceuticals, chemicals, and power generation. However, users must be mindful of their temperature and pressure limitations and perform regular maintenance to ensure the long-term stable operation of the valve.