In both industrial production and everyday life, steam systems are indispensable, and steam traps are critical components that ensure their efficient operation. Among them, bimetallic steam traps play a vital role by automatically discharging condensate and preventing steam loss. In this article, we will take an in-depth look at bimetallic steam traps, explore how they work, and examine their importance, applications, advantages, and key considerations for selection.

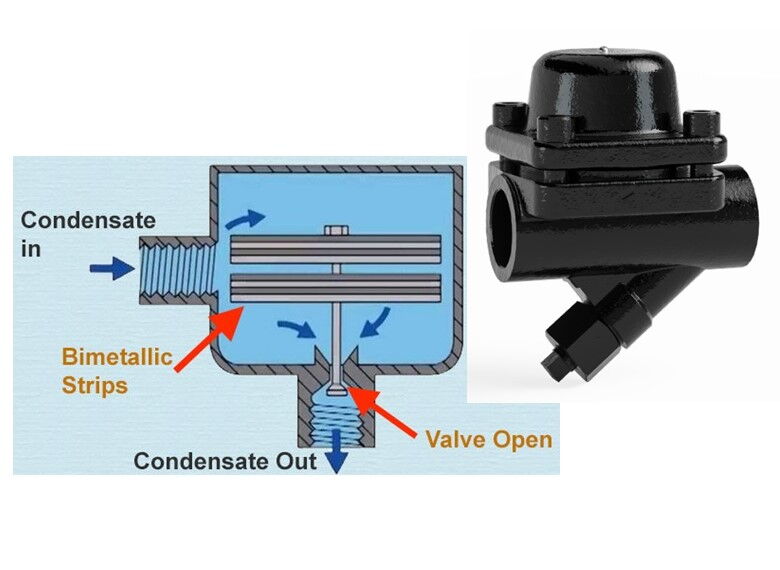

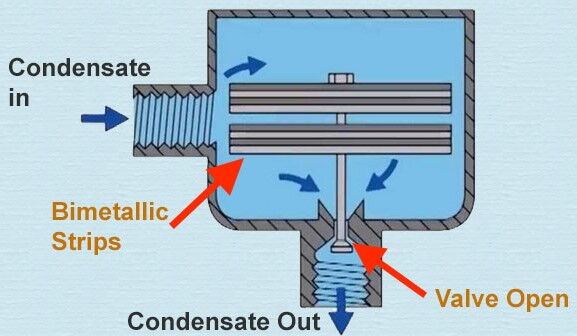

The core component of a bimetallic steam trap is the bimetallic element. This bimetallic element is made by bonding two metal plates with different thermal expansion coefficients together. When the temperature changes, due to the difference in expansion coefficients, the bimetallic element deforms. It is similar to how objects of different materials expand or contract differently in cold and hot weather; the bimetallic element works by utilizing this characteristic.

Specifically, when condensate enters the steam trap, the bimetallic element senses the temperature change. If the temperature is low, the bimetallic element remains flat, and the valve stays open, allowing condensate to discharge smoothly. As the condensate temperature rises, the bimetallic element begins to bend, gradually pushing the valve core toward the closed position. When the temperature reaches a certain value, the valve fully closes, preventing steam leakage. When the condensate temperature decreases, the bimetallic element flattens again, and the valve reopens to continue draining. This cycle repeats, achieving automatic condensate discharge and effective steam isolation.

Simple and easy-to-understand structure: The bimetallic steam trap has a relatively simple structure without complex mechanical components, making its principle easy to understand. Maintenance and repair are also relatively convenient. Even non-professional operators can quickly grasp its basic working principle and perform simple troubleshooting.

- Resistant to water hammer and freezing: Water hammer is common in steam systems and may damage some steam traps. Due to its structural characteristics, the bimetallic steam trap can resist water hammer effectively. It is also less prone to freezing in cold environments, allowing stable operation under harsh working conditions.

- Compact, lightweight, and flexible installation: This steam trap is small in size and light in weight, which does not add a significant burden to the piping system. It can be installed in any position, whether in horizontal or vertical pipes, providing great convenience for system design and installation.

- Energy-efficient: Because the bimetallic steam trap can close the valve before the condensate reaches saturation temperature, high-temperature condensate is always retained upstream, forming steam-water separation and effectively preventing steam leakage. This reduces steam waste, improves energy efficiency, and saves costs for enterprises.

- Automatic air discharge: When the steam system starts, some air often remains in the pipelines. The bimetallic steam trap can automatically discharge this air, ensuring that steam can enter the system smoothly and improving operational efficiency.

- Steam tracing systems: In low-temperature steam tracing processes, the bimetallic steam trap plays an important role. It can control the condensate temperature at a lower level, allowing condensate to accumulate on the inlet side of the trap and use the accumulated sensible heat of the condensate to heat equipment or products. This application is significant for protecting instruments from freezing and heating high-viscosity liquids, ensuring smooth pipeline flow.

- Medium- and low-pressure steam distribution networks: For medium- and low-pressure steam pipelines, the bimetallic steam trap is an ideal choice. It can adapt to conditions with pressures ≤4.0 MPa and condensate discharge rates ≤1.5 t/h, widely used in various medium- and low-pressure steam pipelines, domestic heating, and small process heating. It can effectively discharge condensate, ensuring normal operation of the steam system.

- Fixed discharge temperature limitation: The discharge temperature of a bimetallic steam trap is fixed or adjustable within a limited range. This means it cannot fully adapt to all process types. If the discharge temperature is set improperly, excessive condensate may accumulate, causing production and reliability issues, or even inducing water hammer. Conversely, if the discharge temperature is set too high, the trap cannot close, resulting in continuous steam loss.

- Not suitable for rapid condensate discharge in critical equipment: Due to the working principle of the bimetallic trap, it cannot instantly discharge large amounts of condensate. Therefore, it is not suitable for critical equipment that requires rapid condensate removal. For example, in steam pipelines, failure to discharge condensate promptly may affect steam transport efficiency and quality.

- Bimetallic element fatigue: The bimetallic element may experience fatigue over long-term use, leading to performance degradation or wear and cracking. Regular inspection and adjustment are required, increasing maintenance costs and workload.

- Requires pre-adjustment based on system conditions: Bimetallic steam traps must be adjusted according to specific system conditions before use and cannot automatically adapt to unexpected changes. This requires thorough understanding of system parameters during installation and timely re-adjustment when conditions change.

- Select appropriate discharge temperature according to process requirements: When choosing a bimetallic steam trap, consider the required condensate discharge temperature. If the process allows low-temperature condensate discharge, a trap with a lower fixed discharge temperature can be chosen. If higher-temperature discharge is needed, an adjustable trap should be selected and accurately adjusted according to actual requirements.

- Consider system pressure range: Bimetallic steam traps have applicable pressure ranges, generally with backpressure tolerance greater than 70% or 80%. Ensure the system pressure is within this range; otherwise, the trap may not operate normally. For systems with large pressure fluctuations, consider the trap's adaptability.

- Pay attention to the quality and lifespan of the bimetallic element: The quality of the bimetallic element directly affects the trap's performance and service life. Choose a reliable bimetallic element and be aware of its fatigue life. In high-load, frequent on-off conditions, pay special attention to fatigue issues and consider bimetallic elements with automatic compensation if necessary to extend service life.

- Consider installation location and space constraints: Although bimetallic steam traps can be installed in any position, practical installation must consider piping layout and space constraints. Ensure the trap is easy to operate and maintain and does not interfere with other equipment.

Regularly inspect the bimetallic element: Observe deformation and check for fatigue, wear, or cracks. Replace immediately if issues are found to prevent malfunction.

- Clean the trap interior: Over long-term operation, debris and dirt may accumulate inside the trap, affecting performance. Periodically disassemble and clean the interior to maintain efficiency and accuracy.

- Check and adjust the setting bolts: For traps with adjustable discharge temperatures, regularly check whether the bolts are set according to system requirements. Re-adjust if system conditions change to ensure proper operation.

- Pay attention to sealing performance: Inspect sealing components such as the valve seat and valve core. Replace damaged or worn components to prevent steam leakage, energy waste, and safety hazards.

Besides bimetallic steam traps, there are float-type, inverted bucket, and disc-type steam traps, each with unique characteristics and applicable scenarios.

- Comparison with float-type traps: Float-type traps use the buoyancy of a float to control the valve. They can automatically adjust discharge according to liquid level, suitable for continuous drainage. Bimetallic traps control valve operation based on temperature, better suited for processes with condensate temperature requirements. Float traps are structurally complex and sensitive to water quality, while bimetallic traps are simpler and less demanding on water quality.

- Comparison with inverted bucket traps: Inverted bucket traps use density differences between steam and condensate to control the valve. They can quickly discharge large amounts of condensate, suitable for rapid drainage applications. Bimetallic traps cannot discharge large volumes instantly but have advantages in temperature control. Inverted bucket traps have installation requirements, while bimetallic traps can be installed in any position.

- Comparison with disc-type traps: Disc-type traps operate based on differences in steam and condensate flow velocity. They are compact and effectively prevent steam leakage. Bimetallic traps are structurally more robust, resistant to water hammer and freezing. Disc-type traps are more sensitive to water quality, whereas bimetallic traps are more adaptable.

As a thermal-mechanical steam trap, the bimetallic steam trap, with its unique bimetallic sensing element, can automatically control valve operation according to temperature changes, achieving steam isolation and condensate discharge. It has advantages such as simple structure, resistance to water hammer and freezing, compact size, lightweight, flexible installation, and energy efficiency, and is widely used in steam tracing systems, medium- and low-pressure steam pipelines, and other areas.

However, it also has limitations, including fixed discharge temperature, unsuitability for rapid condensate discharge in critical equipment, bimetallic element fatigue, and the need for pre-adjustment according to system conditions. When selecting a bimetallic steam trap, consider process requirements, system pressure, bimetallic element quality and lifespan, and installation constraints. Regular maintenance is essential to ensure proper operation and extend service life.

With technological development, bimetallic steam traps will move toward improved bimetallic element performance, intelligent control, and multifunctional integration, providing more reliable support for efficient and stable steam system operation.

Bimetallic steam traps play an irreplaceable role under specific conditions. Correct selection, use, and maintenance can effectively improve steam system efficiency, reduce energy consumption, and create economic benefits for enterprises. This article aims to help you better understand bimetallic steam traps and provide a reference for selecting suitable traps for your steam system.