Fireproof and anti-static ball valves are vital for ensuring safety in fluid control systems handling hazardous media, such as flammable gases and explosive substances. These specialized valves incorporate key design features, including fire-resistant materials, metal-to-metal seals, and conductive structures, to prevent leakage, mitigate fire hazards, and eliminate static electricity buildup. Fireproof ball valves maintain sealing integrity during fires, while anti-static ball valves prevent sparks caused by electrostatic discharge. In contrast to common ball valves, which lack these advanced safety mechanisms, fireproof and anti-static valves provide critical protection in high-risk environments. This article explores their design, applications, and the importance of selecting the right valve to safeguard operations in hazardous conditions.

Ball valves are essential components in fluid control systems, particularly in applications where safety is paramount. Fireproof and anti-static ball valves are designed specifically to address the risks associated with flammable, explosive, or electrically hazardous environments. This article delves into the key design features and mechanisms that make these valves ideal for such critical applications.

Fireproof and anti-static ball valves are engineered to meet stringent safety standards in gas pipelines handling flammable and explosive substances like natural gas, liquefied petroleum gas (LPG), and their mixtures. Unlike common ball valves used in non-flammable applications such as water or air pipelines, these specialized valves offer enhanced protection against fire hazards and electrostatic discharge, ensuring operational safety and performance even under extreme conditions.

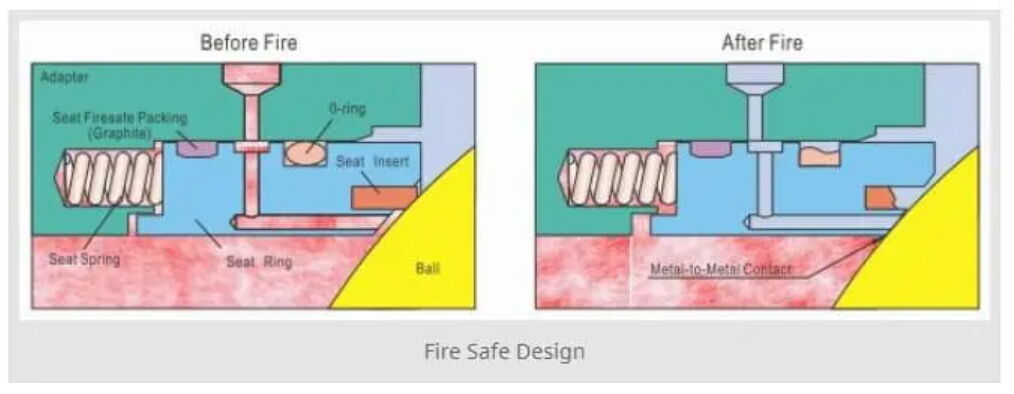

The fireproof design of a ball valve involves multiple safety mechanisms that allow the valve to continue functioning during and after exposure to high temperatures. These features focus on preventing internal and external leakage, maintaining sealing performance, and ensuring structural integrity during a fire.

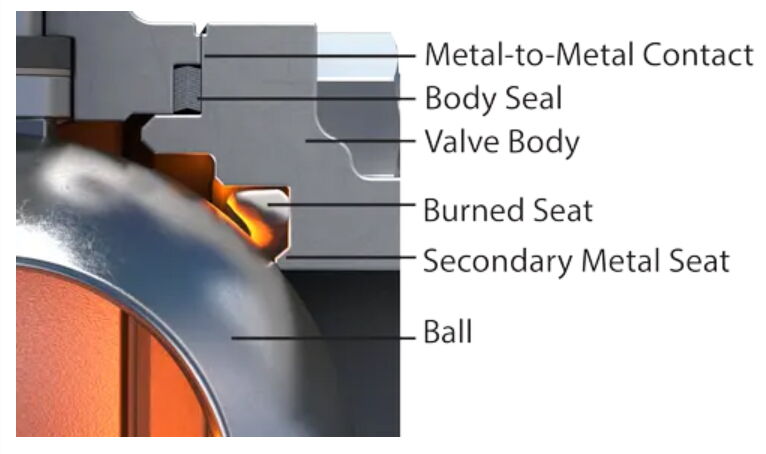

In fireproof ball valves, the ball core and valve seat are designed to handle high temperatures. In the event of a fire, the soft seat, which is typically used in normal operation, may burn away. However, the valve design allows the ball core to be pushed by medium pressure toward the downstream metal seat, forming a hard seal that minimizes internal leakage. This mechanism ensures that the valve remains sealed despite the destruction of the soft seat due to fire.

Metal-to-Metal Seal: Fireproof ball valves incorporate a metal-to-metal seal, which becomes active when the soft seat is burned away, ensuring a continued seal even in the absence of the soft seal.

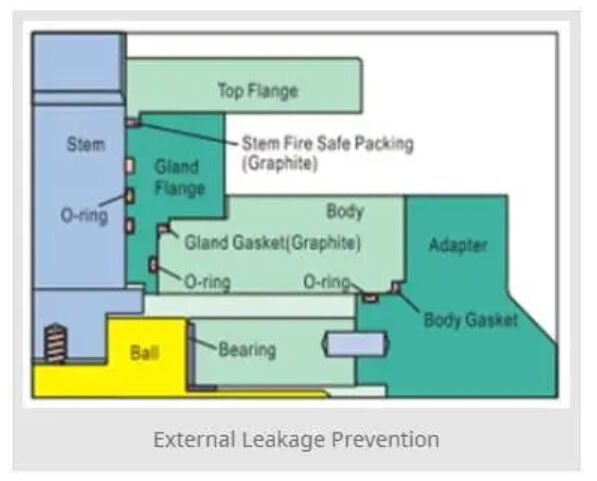

The valve stem is a critical component for preventing fire-related damage. In fireproof valves, high-temperature-resistant materials such as flexible graphite fillers are used for stem packing. These materials prevent PTFE (commonly used for sealing) from melting at high temperatures, which could otherwise cause the stem to become dislodged.

Lower Mounted Valve Stem: To further prevent the valve stem from being pushed out due to internal pressure or fire-related expansion, fireproof valves are designed with a lower mounted valve stem that uses the pressure inside the valve body to compress and maintain a tight seal. This feature also ensures the valve stem remains securely in place during abnormal pressurization conditions.

Fireproof ball valves typically feature a two-piece or three-piece split body construction, sealed with O-rings and graphite metal wound gaskets between the body sections. In the event of a fire, the O-ring may burn out, but the graphite gasket continues to maintain a seal, preventing external leakage.

Metal Contact Seals: Additionally, a metal contact seal is often used between the valve body sections to further enhance fire protection and prevent leakage.

In environments where electrostatic discharge can pose a significant hazard—especially when working with flammable gases or liquids—anti-static ball valves are essential. Static electricity buildup can trigger sparks, which could lead to explosions in hazardous locations. Anti-static ball valves prevent such risks through a specially engineered conductive structure.

The primary goal of the anti-static design is to ensure conductivity between the ball core, valve stem, and valve body. This is achieved by incorporating small metal balls inside drilled holes in the valve stem. These balls are spring-loaded, ensuring that they remain in contact with both the valve stem and the valve body, thus forming an electrical path that dissipates static electricity.

Standards Compliance: According to national standards like GB/T12237, the anti-static resistance in ball valves must be below 10 ohms when the voltage does not exceed 12V. This ensures that any electrostatic buildup is effectively neutralized.

Anti-static ball valves are particularly important in gas pipelines or facilities that handle volatile or flammable media, such as oil refineries, chemical plants, and gas storage facilities. By preventing the buildup of static charges, these valves reduce the risk of spark-induced ignition, ensuring safe and reliable operation in hazardous environments.

While both fireproof and anti-static ball valves are designed with enhanced safety features, common ball valves lack the specialized protection required for hazardous environments. Here's a comparison.

|

Feature |

Fireproof Ball Valves |

Anti-static Ball Valves |

Common Ball Valves |

|

Designed for Hazardous Environments |

Yes, for flammable and explosive media |

Yes, to prevent electrostatic discharge |

No, for non-flammable media |

|

Fire Protection |

Yes, with metal-to-metal sealing and fireproof packing |

No fireproof protection |

No fire protection |

|

Anti-static Protection |

No |

Yes, with conductive structure to prevent static buildup |

No |

|

Construction |

Two-piece or three-piece, split body, O-ring and graphite seals |

Same as fireproof, with conductivity-enhancing components |

Typically one-piece body, no advanced sealing or conductivity |

Fireproof and anti-static ball valves play a crucial role in ensuring safety in pipelines and systems that transport flammable, explosive, or electrically sensitive media. Their unique designs, incorporating fireproof materials, metal-to-metal sealing, and anti-static conductivity are essential for preventing hazardous leaks, static buildup, and other potential dangers in critical applications. Unlike common ball valves, these specialized valves provide the added protection necessary for environments where safety is non-negotiable. By understanding the features and functions of these advanced valve designs, professionals can make informed decisions to enhance the safety and reliability of their systems.