The triple-eccentric butterfly valve is a major innovation in fluid control, designed to address the limitations of traditional butterfly valves under high temperature, high pressure, and zero-leakage conditions. Unlike earlier models, such as the centerline and single-eccentric valves, the triple-eccentric valve uses a third eccentric axis to achieve a twisting motion between the seat and disc, improving sealing performance. This design enhances its ability to operate in extreme environments, offering zero leakage and resistance to high pressures (up to 26 MPa) and temperatures (up to 700°C). Key features include a double safety structure, extended service life, and reduced maintenance costs. Ideal for industries like oil, chemical, and power, the triple-eccentric butterfly valve ensures reliable performance in challenging applications.

Butterfly valves are commonly used fluid control devices, widely applied in industries such as oil, chemicals, power, and metallurgy. As industrial demands for valve performance continue to grow, the limitations of traditional butterfly valves under extreme conditions like high temperature, high pressure, and zero leakage have become increasingly evident. To address these issues, the triple-eccentric butterfly valve was introduced. It not only inherits the advantages of the butterfly valve but also overcomes many of its limitations through unique design and innovative technology, making it one of the key fluid control devices in modern industry.

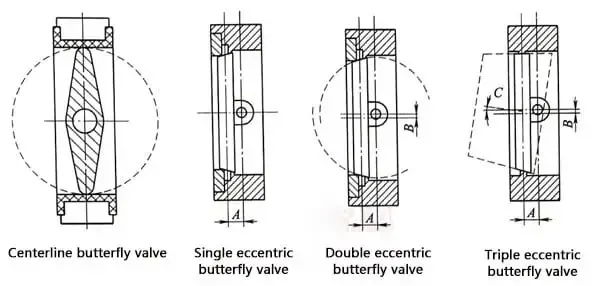

The centerline butterfly valve is the earliest type, characterized by a simple structure where the valve stem, disc, and valve body are aligned at the center. Due to its straightforward design, ease of manufacturing, and lower cost, this type of valve still holds a market share in some standard applications. However, as demands for valve performance increased, the drawbacks of centerline butterfly valves became apparent. The large friction and compression between the disc and seat lead to poor sealing and accelerated wear, especially in high-temperature environments where commonly used elastic materials like rubber and PTFE cannot withstand high heat, affecting the sealing performance. Additionally, the sealing structure of the centerline butterfly valve relies on position sealing, which is ineffective in addressing the zero-leakage problem in high temperature and high-pressure conditions.

To overcome the shortcomings of the centerline butterfly valve, the single-eccentric butterfly valve was developed. By offsetting the axis of the valve stem from the center of the disc, this design changes the angle of contact between the disc and seat, reducing excessive compression and alleviating wear. However, while the single-eccentric design reduces scraping, it still cannot completely eliminate friction, and its sealing performance remains similar to that of the centerline valve. As a result, the application range of the single-eccentric butterfly valve is limited. Under extreme conditions such as high temperature and high pressure, its sealing and durability do not meet the necessary requirements.

The double-eccentric butterfly valve is an improvement on the single-eccentric valve. By introducing a second eccentricity, the structure allows the valve stem to be offset from both the center of the disc and the valve body. This design enables the disc to quickly detach from the seat during opening, significantly reducing friction and scraping. This design reduces switching resistance, minimizes wear, and extends service life. The double-eccentric butterfly valve can be paired with metal seats, making it suitable for higher temperatures and pressures. It performs excellently in high-temperature and corrosive media applications. However, the sealing structure of the double-eccentric valve still relies on position sealing, which means it cannot match the performance of the triple-eccentric valve in some cases, particularly in high-pressure and high-temperature environments.

The triple-eccentric butterfly valve represents a revolutionary improvement over the double-eccentric valve. With the addition of a third eccentricity, it completely addresses the traditional valve's problems in high-pressure, high-temperature, and zero-leakage applications. The most significant innovation of the triple-eccentric design is that the third eccentric axis causes the sealing surface to no longer make linear contact. Instead, the seal is achieved through a twisting motion. This design allows the valve to withstand higher temperatures and pressures, making it suitable for even more demanding working environments.

The sealing structure of the triple-eccentric butterfly valve relies on contact surface pressure from the seat, rather than elastic deformation, providing more stable sealing performance. The contact between the seat and the disc is achieved through twisting force, reducing the reliance on elastic materials, and making the sealing effect more reliable. Its zero-leakage characteristics make it ideal for use in industries such as oil, chemicals, and power, especially in high-temperature, high-pressure, and highly corrosive media environments.

The triple-eccentric butterfly valve offers unique advantages in complex working conditions. Its design and manufacturing incorporate several key technical features that enhance its performance and ensure stable operation in high-pressure, high-temperature, and harsh environments.

The triple-eccentric butterfly valve features a double safety design. Two independent thrust rings are positioned beneath the valve plate to prevent deformation due to excessive fluid pressure and temperature. Additionally, the valve stem is equipped with an anti-ejection mechanism to prevent stem damage or ejection in the event of an emergency, ensuring equipment safety and stability.

The valve plate of the triple-eccentric butterfly valve adopts an elliptical cone shape with a surface welded with hard alloys for excellent wear resistance. The floating U-shaped stainless-steel seat has automatic centering adjustment, meaning that when the valve opens, the plate automatically separates from the seat, avoiding dead-zone phenomena. The valve opens and closes more smoothly. As the plate rotates, the seat automatically adjusts to ensure a tight seal, greatly improving control accuracy and regulating ratio.

The sealing system of the triple-eccentric butterfly valve does not rely on elastic deformation of the seat but uses contact surface pressure for sealing, achieving true zero leakage. This structure allows stable operation in high temperatures (up to 700°C) and high pressures (up to 26 MPa), making it suitable for high-temperature, high-pressure, and highly corrosive media applications, solving the sealing and durability problems that traditional butterfly valves cannot address.

The compact structure design of the triple-eccentric butterfly valve reduces direct contact between the seat and the medium, effectively minimizing corrosion of the seat. The corrosion and wear issues of the seat are well-controlled, and the sealing surface of the disc can be replaced independently, significantly reducing maintenance and replacement costs. Thanks to this design, the triple-eccentric butterfly valve has a longer service life and lower operational costs.

The introduction of the triple-eccentric butterfly valve marks a major breakthrough in valve technology. By adding a third eccentric axis, it effectively solves the performance limitations of traditional butterfly valves in high-temperature, high-pressure, and high-leakage applications, making it an ideal choice for many challenging operating conditions. Its zero-leakage, high-temperature and pressure resistance, long service life, and low maintenance costs make the triple-eccentric butterfly valve a promising option for industrial applications, especially in fields such as oil, chemicals, and power, where high temperatures, pressures, and special media control are essential. As technology continues to advance, the range of applications and performance of the triple-eccentric butterfly valve will be further enhanced, driving innovation and development in modern industry.