This article provides a detailed comparison between plug valves and ball valves, two commonly used quarter-turn valves in fluid control systems. It covers their structure, functions, advantages, and limitations. Ball valves, known for their simple design and low pressure drop, are ideal for automated control and high-flow applications. Plug valves, on the other hand, offer larger sealing surfaces and are better suited for handling abrasive or corrosive media. The article explores the differences in structural design, fluid control performance, and maintenance considerations, helping readers understand which valve type is best suited for specific applications, including industries such as petrochemical, oil, and gas.

Valves are crucial components in fluid control systems, where their design, structure, and operation directly impact the efficiency and precision of fluid flow control. Among the many valve types, plug valves and ball valves are two commonly used quarter-turn valves that regulate fluid flow by rotating their closure elements. Despite sharing a similar operating principle, plug valves and ball valves have distinct advantages and suitable applications due to their differences in structure, operation, and field of use. Below is a detailed comparison of both valves, covering their structure, functions, applications, and advantages and disadvantages.

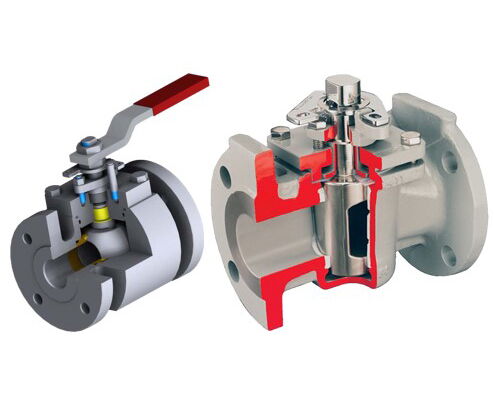

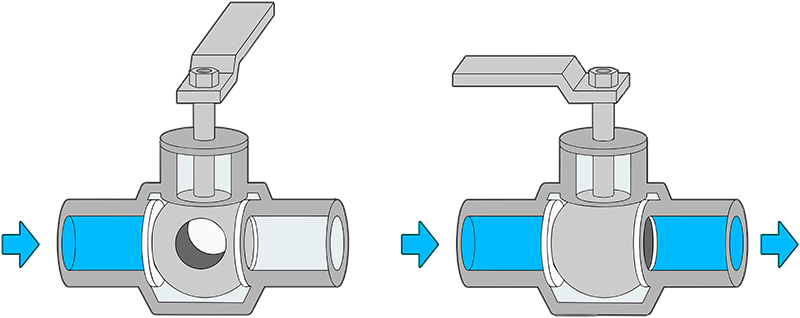

A ball valve controls fluid flow by rotating a spherical ball with a hole or passage through it. The basic structure consists of a ball, valve body, valve seat, and stem. The ball typically has a round hole or passage, and the flow is adjusted by rotating the ball. When the ball is rotated 90 degrees, the passage is either fully opened or closed, thereby controlling the flow of fluid.

Ball Design: The closure element in ball valves is a spherical ball with a circular passage that regulates fluid flow by rotating the ball.

Streamlined Flow Path: Ball valves have a fully parallel valve body cavity, which provides minimal flow resistance, making them ideal for applications that require low pressure drop.

Ease of Operation: Due to their simple rotational design, ball valves have a lower operating torque and are easy to maintain, making them widely used in automated control systems.

Ball Valve Advantages: Ball valves are easy to operate with low torque, feature a compact design, and their sealing surfaces avoid erosion when closed. They also provide low pressure drops, making them suitable for applications requiring minimal resistance. Their maintenance is simple, and they have a wide range of applications, particularly in multi-channel flow and flow control.

Ball Valve Limitations: Although ball valves offer good sealing performance, their sealing surface is smaller, which could lead to leakage under high pressure and high flow conditions. In extreme operating conditions, the sealing performance of ball valves may be challenged.

Ball valves are widely used for opening and closing media in pipelines, especially in industries such as natural gas, crude oil transportation, LNG plants, polymer production, and natural gas processing. Ball valves are also extensively used for regulating and controlling flow, particularly hard-sealed V-ball valves, which can handle fluid media containing fibers or solid particles.

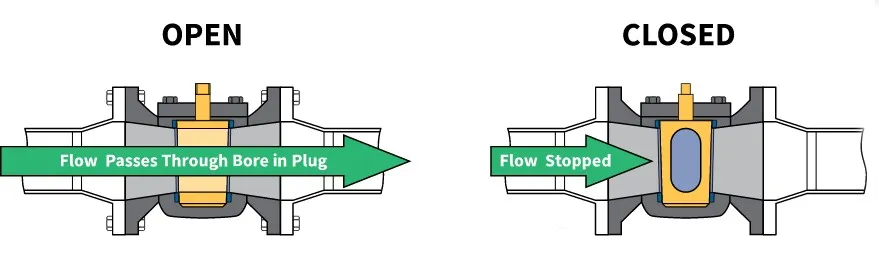

A plug valve controls fluid flow using a rotating plug as the closure element. Its basic structure consists of a valve body, plug, and seat, with the plug being either cylindrical or conical in shape. By rotating the plug 90 degrees, the passage on the plug aligns or separates from the passage in the valve body, thereby opening or closing the valve.

Plug Shape: Plug valves typically have either cylindrical or conical plugs. Cylindrical plugs usually feature a rectangular passage, while conical plugs have a trapezoidal passage.

Sealing Performance: The large sealing surface of a plug valve enhances its sealing capability, making it suitable for applications requiring high sealing performance.

Motion Characteristics: During operation, the plug valve's sealing surface exerts a wiping action and prevents contact with the fluid in the fully open state, making it ideal for media containing suspended particles.

Plug Valve Advantages: Plug valves offer a larger sealing surface, which improves sealing performance, and are well-suited for fluid media with particles. Their compact design allows for multi-channel structures, simplifying pipeline systems and reducing the number of required valves.

Plug Valve Limitations: Operating plug valves requires greater torque, and the restricted flow area can cause pressure drops, which is a disadvantage compared to ball valves.

Plug valves are widely used in oilfield exploration, transportation, and refining equipment. They are also suitable for industries such as petrochemical, chemical, gas, natural gas, liquefied petroleum gas, and HVAC. They are primarily used for cutting off, connecting, and diverting fluid flow. In certain applications, they can also be used for throttling, especially when the plug's sealing surface has good erosion resistance.

Despite both being quarter-turn valves, the design and performance differences between plug valves and ball valves make them suitable for different application scenarios. Below are the key differences between the two valves.

Plug Valve: Plug valves feature larger sealing surfaces, which offer stronger sealing capabilities, but require greater torque to operate. The design of plug valves makes them more adaptable to abrasive media.

Ball Valve: Ball valves have a simpler structure and smaller operating torque. Their parallel valve body cavity results in minimal flow resistance, making them suitable for applications requiring large flow and low pressure drop. Ball valves are more versatile in switching between multiple channels.

Plug Valve: Plug valves control fluid flow by rotating the plug, making them suitable for applications requiring large flow openings and closures. However, their flow passages may cause some pressure drop.

Ball Valve: Ball valves offer more direct flow paths with minimal pressure drop, making them ideal for low-pressure-drop applications. The simple ball design also makes them more advantageous in flow regulation and control.

Plug Valve: Plug valves have a simple design, are easy to maintain, and experience minimal wear on the valve body and plug during operation. Replacing the liner and top seal can help maintain long-term functionality.

Ball Valve: Maintenance of ball valves is relatively complex, especially because debris can accumulate inside the ball. Cleaning and maintenance require more effort. However, ball valves are easier to operate and have a longer service life.

Plug Valve: Plug valves are suitable for handling corrosive and abrasive materials, excelling in applications involving wastewater, slurries, and pastes.

Ball Valve: Ball valves are ideal for automated control, natural gas transport, oil and gas pipelines, LNG processing, and other high-precision, high-flow applications. They are especially effective in situations that require low pressure drop.

Although both plug valves and ball valves are quarter-turn valves, they exhibit significant differences in structure, operational characteristics, and suitable applications. Plug valves are ideal for applications requiring large sealing surfaces, corrosion, and abrasion resistance, particularly when handling fluid media with suspended particles. Ball valves, on the other hand, are preferred for their easy operation, precise flow control, and pressure drop reduction, making them widely used in automated control and low-resistance flow regulation applications. The choice between a plug valve and a ball valve depends on specific application requirements, fluid characteristics, and maintenance considerations.