Read the latest news on industrial valves and valve technologies. Here, you'll find updates on new products, helpful maintenance tips, and the latest trends in the industry. Whether you're interested in learning about new valve features, ways to keep your equipment running smoothly, or what's coming next in valve technology, we've got you covered with all the essential information.

85-96 of 156 results

Needle Valves: Precision Regulators in Industrial Control

Industry News

Oct 17, 2025

22

In the complex networks of modern industry, valves play a crucial role, precisely controlling the direction, pressure, and flow of fluids. From petroleum refining to chemical production, from pharmaceutical processes to food processing, valves are ubiquitous. Among the many types of valves,...

Weir Diaphragm Valves vs. Straight-Through Diaphragm Valves

Industry News

Oct 16, 2025

12

In the industrial field, diaphragm valves, as an important control element, are widely used in various fluid control occasions. Diaphragm valves, with their unique structure and performance advantages, play a key role in industries such as chemical, pharmaceutical, food, and water treatment....

How to Choose the Right Plug Valves?

Industry News

Oct 15, 2025

11

In the industrial field, valves are key devices for controlling fluid flow. As a long-established and widely used type of valve, plug valves play an important role in many industrial scenarios due to their unique structure and performance characteristics. A plug valve is a valve that controls...

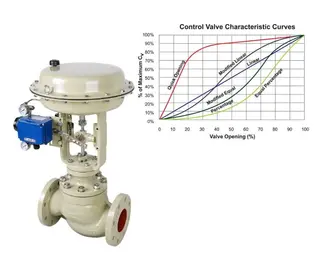

Flow Characteristics of Control Valves

Industry News

Oct 14, 2025

24

In the field of industrial automation control, control valves play an indispensable role. They act as precise flow regulators, adjusting the fluid flow by controlling the valve opening and closing, thereby achieving precise control of the production process. The flow characteristics of a control...

Basket Strainer vs. Y-Type Strainer: Major Differences

Industry News

Oct 13, 2025

49

In industrial production, the purity of fluids is crucial to the stability of the entire production process and the quality of the final products. Whether in the chemical, petroleum, pharmaceutical, or food industries, effective filtration equipment is required to remove impurities from fluids,...

How to Choose the Right Steam Trap: A Comprehensive Guide

Industry News

Oct 11, 2025

23

In industrial production, the normal operation of fluid systems is crucial to production efficiency and product quality. As a key component of fluid systems, the correct selection of a steam trap directly affects the operational efficiency and safety of the entire system. This article provides a...

Guide to Valve Performance and Selection

Industry News

Oct 10, 2025

7

In industrial production, valves play a crucial role. They not only control the flow of fluids but also ensure the safety and efficiency of systems. However, faced with numerous types of valves and complex operating conditions, how can one choose the right valve? This article will deeply explore...

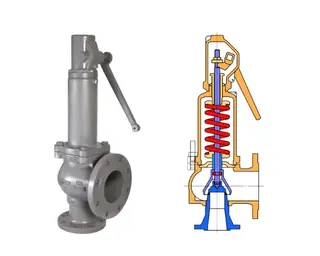

Guide to Key Steps of Safety Valve Adjustment

Industry News

Oct 09, 2025

17

In industrial production, safety valves are essential devices for ensuring the safe operation of equipment. They can automatically open when the internal pressure of equipment exceeds the set value, releasing excess pressure and preventing the equipment from experiencing danger due to...

Complete Guide to Installing Pneumatic Diaphragm Valves

Industry News

Sep 30, 2025

41

In industrial production, pneumatic diaphragm valves, as an important control component, are widely used in the transportation and control of various fluid media. However, proper installation is the key to ensuring normal operation and extending the service life of pneumatic diaphragm valves....

Valve Stem Sealing: Ensuring Safe Operation of Valves

Industry News

Sep 22, 2025

14

In industrial production, valves are indispensable equipment, and the valve stem, as one of the core components of a valve, directly affects the safety and stability of the entire system. The valve stem not only has to withstand the pressure of the medium but also deal with pressure changes...

Control Valve Plugs: Core Component of Industrial Automation

Industry News

Sep 20, 2025

24

In the field of industrial automation, control valves play a crucial role, and the valve plug is the core component of a control valve. The valve plug is not only the movable part of the control valve but also the key element for achieving fluid control. It fits tightly with the valve seat,...

An Introduction to Full-Lift Safety Valve

Industry News

Sep 19, 2025

72

Among the many types of safety valves, the full-lift safety valve, with its unique design and outstanding performance, has become a widely used safety device in the industrial field. The opening height of a full-lift safety valve is greater than or equal to one-quarter of the flow channel...

Total 156 Records, 12 records per page