Read the latest news on industrial valves and valve technologies. Here, you'll find updates on new products, helpful maintenance tips, and the latest trends in the industry. Whether you're interested in learning about new valve features, ways to keep your equipment running smoothly, or what's coming next in valve technology, we've got you covered with all the essential information.

Valve Leakage and Maintenance Measures

Valves are vital components in industrial systems, but prolonged exposure to harsh working conditions can lead to issues such as leakage and operational stiffness, affecting stability and safety. This article identifies common causes of valve problems, including body and bonnet leakage, sealing ring issues, and valve stem stiffness. It discusses various repair methods, such as adhesive repair, diverting welding, and sealing ring maintenance, to address these issues. Furthermore, it emphasizes the importance of precise machining, lubrication, and regular inspection for preventing valve stem stiffness and packing leakage. By following effective maintenance strategies, valves can operate reliably and efficiently, ensuring prolonged service life and improved system performance.

What are Differences between Gate Valves and Globe Valves

Gate valves and globe valves are both essential components in industrial piping systems, each with distinct characteristics suited to different applications. While both control fluid flow, they operate based on different principles and offer varying performance features. This article compares gate valves and globe valves, focusing on their working principles, structural characteristics, applications, and advantages and disadvantages. Gate valves are ideal for large flow systems requiring full opening or closing, while globe valves are more suitable for precise flow regulation and throttling. Understanding the strengths and limitations of each valve type is crucial for selecting the appropriate valve for specific industrial needs.

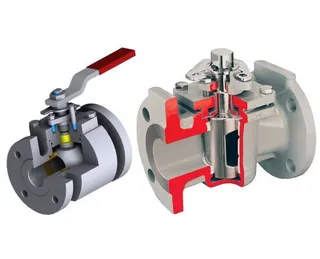

What is Fireproof and Anti-static Design for Ball Valves

Fireproof and anti-static ball valves are vital for ensuring safety in fluid control systems handling hazardous media, such as flammable gases and explosive substances. These specialized valves incorporate key design features, including fire-resistant materials, metal-to-metal seals, and conductive structures, to prevent leakage, mitigate fire hazards, and eliminate static electricity buildup. Fireproof ball valves maintain sealing integrity during fires, while anti-static ball valves prevent sparks caused by electrostatic discharge. In contrast to common ball valves, which lack these advanced safety mechanisms, fireproof and anti-static valves provide critical protection in high-risk environments. This article explores their design, applications, and the importance of selecting the right valve to safeguard operations in hazardous conditions.

The Development of Triple-Eccentric Butterfly Valves

The triple-eccentric butterfly valve is a major innovation in fluid control, designed to address the limitations of traditional butterfly valves under high temperature, high pressure, and zero-leakage conditions. Unlike earlier models, such as the centerline and single-eccentric valves, the triple-eccentric valve uses a third eccentric axis to achieve a twisting motion between the seat and disc, improving sealing performance. This design enhances its ability to operate in extreme environments, offering zero leakage and resistance to high pressures (up to 26 MPa) and temperatures (up to 700°C). Key features include a double safety structure, extended service life, and reduced maintenance costs. Ideal for industries like oil, chemical, and power, the triple-eccentric butterfly valve ensures reliable performance in challenging applications.

Ball Valve vs. Plug Valve: Structure, Function & Application

This article provides a detailed comparison between plug valves and ball valves, two commonly used quarter-turn valves in fluid control systems. It covers their structure, functions, advantages, and limitations. Ball valves, known for their simple design and low pressure drop, are ideal for automated control and high-flow applications. Plug valves, on the other hand, offer larger sealing surfaces and are better suited for handling abrasive or corrosive media. The article explores the differences in structural design, fluid control performance, and maintenance considerations, helping readers understand which valve type is best suited for specific applications, including industries such as petrochemical, oil, and gas.

How to Choose Valves for the Chemical Industry

This article explores the critical role of valves in the chemical industry, emphasizing their function in regulating flow, pressure, and temperature under challenging operating conditions. With chemical processes involving highly corrosive, high-temperature, and high-pressure media, valves must be designed for exceptional sealing, corrosion resistance, and operational reliability. The material selection for valves is particularly crucial, including stainless steel, titanium, and nickel-based alloys, with specialized linings for highly aggressive substances. Additionally, the article examines the importance of sealing materials and temperature and pressure resistance, ensuring valve durability in extreme environments.

Comparison of Spring-Loaded & Lever-operated Safety Valves

This article compares two primary types of safety valves, spring-loaded and lever-operated, used in pressure vessels and piping systems. Safety valves are essential for preventing hazardous conditions caused by excessive pressure. The spring-loaded safety valve operates by using the elastic force of a spring to open the valve when pressure exceeds a preset value, offering compact design and flexibility for installations in tight spaces. However, it is sensitive to high temperatures and may experience fatigue over time. In contrast, lever-operated safety valves use a lever and weight mechanism to balance the pressure and open the valve, making them ideal for high-temperature and high-pressure environments. They offer long-term stability but require more space and can be sensitive to vibrations.

Structure and Performance of the Tilting Disk Check Valve

The Tilting Disk Check Valve is a highly effective solution for preventing fluid backflow in modern pipeline systems. Its unique design, featuring a butterfly-shaped tilting valve disk, ensures rapid closing, efficient sealing, and effective suppression of impacts and water hammer. This valve's working principle leverages fluid flow rate and gravity to automatically close the valve when backflow occurs, providing quick and reliable sealing. Key advantages include low noise, high sealing performance, energy efficiency, and a long service life due to the frictionless interaction between the valve disk and seat. The Tilting Disk Check Valve is particularly suitable for horizontal and vertical pipeline systems in industries such as oil and gas, water treatment, and chemical processing. Its structural optimization and performance make it a crucial component in maintaining system stability and preventing reverse flow.

Knife Gate Valves: Unidirectional vs. Bidirectional

This article compares unidirectional and bidirectional knife gate valves, commonly used shut-off valves in fluid control systems across various industries such as water, oil, gas, and chemicals. Unidirectional knife gate valves are designed for single-direction flow, offering a simple sealing mechanism ideal for conventional fluids in low-pressure systems. However, they are prone to sealing failures when handling solid particles. In contrast, bidirectional knife gate valves accommodate two flow directions, providing superior sealing performance and reliability under higher pressures and complex fluid conditions. While bidirectional valves offer more flexibility and better performance, they come with higher costs and operational requirements. By understanding the differences in sealing design, installation requirements, and cost-effectiveness, users can make informed choices based on their specific application needs, ensuring improved system reliability and operational efficiency.

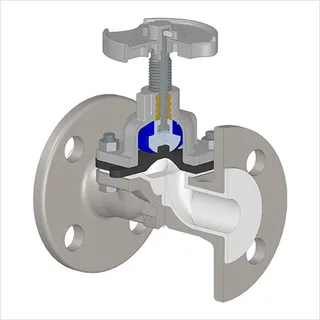

What are Diaphragm Valves?

Diaphragm valves are specialized shut-off valves widely used for fluid isolation, regulation, and control in industries requiring high hygiene and safety standards. The valve's unique design features an elastic diaphragm, which moves to open or close the fluid passage, ensuring precise flow control. Key advantages include simple structure, easy maintenance, fluid isolation, contamination prevention, and suitability for handling corrosive, viscous, or particulate-laden fluids. Diaphragm valves are commonly used in food, pharmaceutical, chemical, and power industries. Fluorine-lined versions offer enhanced chemical resistance for demanding applications. However, diaphragm valves are best suited for low-pressure and low-temperature environments, with regular maintenance required to ensure reliable operation.

Rising Stem Gate Valve vs. Non-Rising Stem Gate Valve

Gate valves are vital components in industrial piping systems, used for controlling fluid flow. This article compares two main types of gate valves, rising stem and non-rising stem, highlighting their structural differences, advantages, disadvantages, and appropriate applications. Rising stem gate valves, with visible stem movement, are ideal for low-pressure, small-flow systems that require frequent visual inspection and simple maintenance. In contrast, non-rising stem gate valves feature a compact design, making them more suitable for confined spaces and high-pressure, high-flow applications. They offer better resistance to environmental contamination and are well-suited for automated systems. The article concludes by providing guidance on choosing the appropriate valve based on factors like installation space, medium characteristics, and operational requirements.

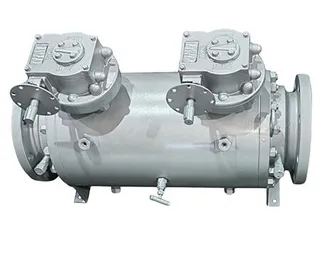

What are Double Block and Bleed Ball Valves?

A Double Block and Bleed (DBB) ball valve integrates two standard ball valves into a single unit, providing superior fluid control and safety in pipeline systems. This article explores the design, working principles, sealing performance, and advantages of DBB ball valves. It emphasizes their dual isolation and bleed functionality, making them ideal for preventing leaks and enhancing operational safety, especially in high-pressure applications. The valve’s simplified installation and maintenance processes further reduce system complexity and downtime. Additionally, advanced design features such as fire-safe, anti-static, and anti-operation designs ensure the valve's adaptability to complex operating conditions. The DBB ball valve's efficiency, safety, and reliability make it a critical component in industries like oil, gas, chemicals, and energy.

Total 156 Records, 12 records per page