This article compares floating ball valves and trunnion mounted ball valves, highlighting their structural differences, applications, sealing performance, and suitability for various working conditions. Floating ball valves, with a simpler design, are ideal for low to medium-pressure systems handling clean fluids, offering cost-effectiveness and reliable sealing under moderate conditions. In contrast, trunnion mounted ball valves are more complex, designed for high-pressure, high-temperature environments, and are well-suited for applications involving high-viscosity or solid-particle-containing media. The article examines their performance in flow regulation, sealing reliability, and installation considerations, providing guidance on selecting the right valve type based on specific operational requirements.

Floating ball valves and trunnion mounted ball valves are two common types of ball valves used in industrial pipeline systems. They differ significantly in structural design, applicable scenarios, sealing performance, and other aspects. By comparing the characteristics of these two types of ball valves, we can better understand their respective advantages and disadvantages, thereby selecting the appropriate valve type to meet the requirements of different working conditions.

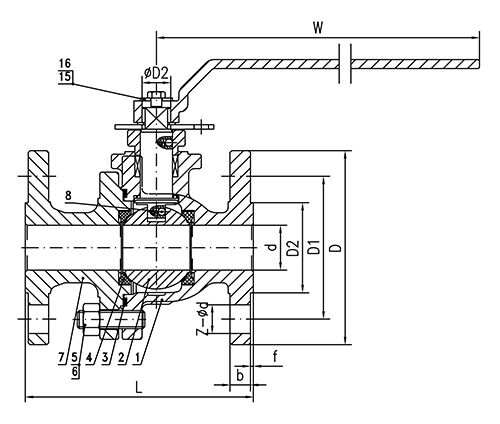

Floating Ball Valve: The core feature of a floating ball valve is that the ball can move freely within the valve body. When the valve is closed, the ball is pushed by the medium pressure towards the sealing surface on the outlet side, forming a seal. Floating ball valves typically have only an upper stem, allowing the ball to move slightly, which is why they are called "floating" ball valves. This design is suitable for low to medium-pressure conditions, especially in applications where relatively simple sealing performance is required.

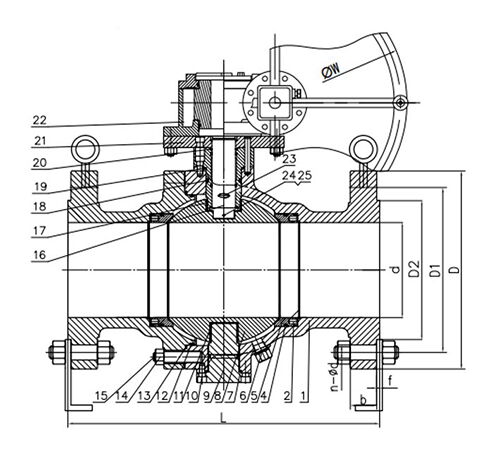

Trunnion Mounted Ball Valve: In contrast, the ball in a trunnion mounted ball valve is supported by a trunnion or shaft at the bottom, preventing it from moving within the valve body. When the valve is closed, the seat moves under the pressure of the medium, coming into contact with the fixed ball to achieve sealing. The design of trunnion mounted ball valves is more complex, making them suitable for high-pressure and high-temperature conditions, particularly in applications requiring higher mechanical load capacity.

Floating Ball Valve: Floating ball valves are generally suitable for low to medium-pressure conditions. The ball can tightly contact the sealing surface under pressure, ensuring effective sealing. Common applications include pipeline systems with nominal pressures up to PN16, such as industrial water and gas transmission pipelines. Floating ball valves offer significant cost-performance advantages in scenarios requiring simple sealing and flow control, making them suitable for handling ordinary fluid media.

Trunnion Mounted Ball Valve: Trunnion mounted ball valves are suitable for high-pressure, high-temperature, and high-precision flow control applications. Due to the fixed ball design, the sealing is more reliable, and they can withstand higher medium pressures, making them ideal for high-pressure pipeline systems with nominal pressures of PN160 and above. For example, trunnion mounted ball valves are commonly used in high-pressure pipelines in the petrochemical industry. Additionally, trunnion mounted ball valves are suitable for high-viscosity, crystallizable, or solid-particle-containing media, as their design can better handle the challenges posed by erosion and wear.

Floating Ball Valve: The sealing performance of floating ball valves is significantly influenced by medium pressure. Since the ball is floating, it tightly presses against the sealing ring on the outlet side under high pressure, forming an effective seal. The sealing performance of floating ball valves remains relatively stable under low-pressure and high-temperature conditions, making them suitable for such environments.

Trunnion Mounted Ball Valve: The sealing performance of trunnion mounted ball valves relies on the design of the seat, typically featuring a double-sided forced sealing structure. The ball and seat are tightly pressed together by medium pressure, ensuring a reliable seal. In high-pressure and high-temperature environments, trunnion mounted ball valves offer more dependable sealing performance, especially in applications where the medium is highly erosive.

Floating Ball Valve: Floating ball valves are suitable for relatively clean liquid and gas media. Their simple design allows the floating ball to avoid blockage by solid particles, making them ideal for applications requiring high media purity. For instance, floating ball valves are used in high-purity gas transmission in the electronics industry and sterile gas and liquid transmission in the pharmaceutical industry, reducing media retention and contamination within the valve.

Trunnion Mounted Ball Valve: Trunnion mounted ball valves are suitable for various complex media, especially high-viscosity, crystallizable, or solid-particle-containing media. The fixed ball design allows them to withstand significant mechanical loads and resist media erosion, ensuring the durability of the sealing surface. They are commonly used in chemical production, particularly for transporting slurries or highly viscous materials, where they provide better sealing performance and longer service life.

Floating Ball Valve: Floating ball valves have relatively limited flow control capabilities, primarily relying on the floating movement of the ball. Due to this design, they may not perform as well as trunnion mounted ball valves in high-pressure and high-flow applications. However, in scenarios where precise flow control is not critical, floating ball valves can still meet requirements and offer cost-performance advantages due to their simple structure and lower cost.

Trunnion Mounted Ball Valve: Trunnion mounted ball valves offer superior flow regulation characteristics, especially when fully open, as they provide a smooth flow path with minimal pressure loss, enabling better flow control. They are ideal for applications requiring precise flow control, such as material proportioning in large chemical plants or hot water flow regulation in heating systems.

Floating Ball Valve: Floating ball valves are mainly used in pipeline branch positions as auxiliary shut-off or regulating valves. They are easy to operate and commonly used in low to medium-pressure systems. Due to their lower cost, they are often chosen for applications requiring low operating force and less precise control.

Trunnion Mounted Ball Valve: Trunnion mounted ball valves are typically installed at critical pipeline locations, such as main pipeline inlets and outlets or connections to important equipment. They are primarily used for precise control and reliable shut-off of medium flow and pressure. Due to their strong sealing performance and ability to handle high-pressure and high-temperature conditions, trunnion mounted ball valves play a crucial role in key systems.

Floating ball valves and trunnion mounted ball valves each have distinct advantages and are suitable for different working conditions. Floating ball valves, with their simple structure, low cost, and good cost-performance ratio, are widely used in low to medium-pressure systems handling clean fluid media. In contrast, trunnion mounted ball valves offer stronger sealing capabilities and are suitable for high-pressure, high-temperature, and high-load conditions, particularly in applications involving high-viscosity, solid-particle, or complex media.

Selecting the appropriate ball valve type requires considering the specific working conditions, including media characteristics, pressure, temperature, and the need for precise flow control, to ensure the safety and efficiency of the system.