Wedge gate valves are vital components in pipeline systems, using a wedge-shaped gate to achieve sealing. These valves come in three main structural types: flexible wedge, solid wedge, and double-disc wedge, each offering unique advantages based on operating conditions. The flexible wedge is ideal for environments with temperature fluctuations, as it compensates for thermal expansion. Solid wedge valves are simpler but prone to jamming in high-temperature conditions. The double-disc wedge design provides better sealing and durability, especially in high-temperature and high-pressure environments. Selecting the right wedge gate valve depends on factors such as temperature, pressure, and media type to optimize performance and longevity.

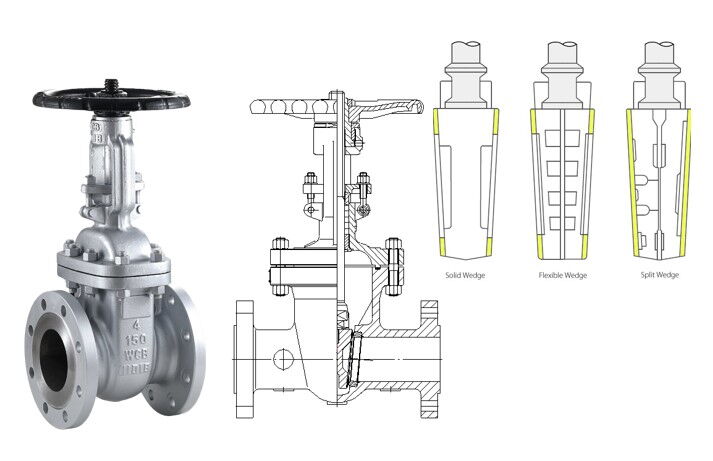

Wedge gate valves are a common type of gate valve widely used in various pipeline systems, achieving sealing through a wedge-shaped gate. Their sealing performance and structural design directly impact the valve's operational efficiency and lifespan. The wedge-shaped gate in a wedge gate valve is typically divided into three main structures: flexible wedge, solid wedge, and double-disc wedge. Each design has its unique advantages and disadvantages, making them suitable for different working environments and media conditions. Below, we will explore wedge gate valves and their three common structural types in detail.

The key to the design of a wedge gate valve lies in the structure of the wedge-shaped gate. The sealing surfaces on both sides of the wedge are inclined at a certain angle relative to the vertical centerline of the gate, known as the wedge half-angle. The size of the wedge half-angle significantly affects the valve's performance. Common wedge half-angles are 2°52' and 5°. A smaller wedge half-angle reduces the force required to close the valve, but the wedge gate is prone to jamming when pipeline deformation occurs due to temperature changes. Conversely, a larger wedge half-angle mitigates this issue but requires more force to close the valve.

The flexible wedge gate valve has a simple structural design and excellent sealing performance, making it particularly suitable for environments with significant temperature fluctuations. The sealing surface of the flexible wedge is machined with an annular groove, which allows the gate to have a certain degree of elastic deformation. This ensures that when the valve is closed, the slight deformation of the gate compensates for machining deviations, ensuring a tight fit between the gate sealing surface and the valve seat, thereby achieving an effective seal.

The primary advantage of the flexible wedge gate valve is its ability to avoid jamming caused by thermal expansion or contraction due to temperature changes. When the valve is closed, the flexible wedge relies on its own elastic load to apply sealing force to the valve seat, rather than depending on the wedging force of the valve stem. This allows the flexible wedge to maintain excellent sealing performance under conditions of thermal expansion, contraction, and pipeline deformation. Additionally, the flexible wedge has lower precision requirements for wedge angle machining, resulting in relatively lower production and maintenance costs.

Flexible wedges are suitable for small and medium-sized gate valves, especially in applications with significant temperature variations. However, in media containing a high amount of solid particles, the annular groove may become clogged, affecting the gate's ability to deform elastically. Therefore, flexible wedges are not suitable for media with a high concentration of solid particles.

The solid wedge is a single-piece, solid structure that lacks the ability to compensate for changes in valve seat alignment caused by pipeline loads or thermal fluctuations. The machining precision requirements for the wedge half-angle are very high, making the manufacturing and maintenance of solid wedges relatively complex. In operation, the sealing surfaces on both sides of the solid wedge are prone to wear, and in high-temperature environments, temperature changes can cause the gate to jam, affecting the valve's normal operation.

The main advantage of the solid wedge gate valve is its simple structure, making it suitable for smaller valves and applications with lower pressure-temperature conditions. However, due to its lack of elastic deformation capability, the solid wedge is prone to jamming when subjected to pipeline deformation or thermal fluctuations, and its use is limited in high-temperature conditions. Therefore, solid wedges are not recommended for environments with temperatures exceeding 121°C (250°F).

Solid wedges are typically used in small gate valves with a diameter of DN50 (NPS2) or smaller, suitable for low pressure-temperature conditions. Their application range is relatively narrow, usually limited to low-temperature and low-pressure pipelines.

The double-disc wedge consists of two gates hinged together with a spherical center, allowing for free angle adjustment to ensure a good fit with the valve seats on both sides. In the design of the double-disc wedge, the wedge angle of the sealing surface is automatically adjusted by the spherical hinge, reducing the precision requirements for wedge angle machining. This design makes the double-disc wedge less prone to jamming during temperature changes and reduces the risk of scuffing.

The primary advantage of the double-disc wedge is its ability to solve the jamming issues common in single-disc designs. When the valve body experiences slight distortion due to pressure or torque, the double-disc structure can still ensure normal valve operation. Before the valve opens, the sealing load on the valve seat is already relieved, allowing the two independent gates to function properly even if the valve body is slightly distorted. Additionally, the double-disc wedge has better deformation compensation capabilities, reducing sealing surface wear and internal leakage.

Double-disc wedges are highly suitable for high-temperature and high-pressure pipeline systems, especially in conditions with significant temperature variations or pipeline deformation. Their structure effectively prevents jamming and reduces friction between the valve seat and the gate, extending the valve's service life. However, due to their complex structure and numerous components, double-disc wedges are not suitable for viscous or crystallizing media, where scaling or bonding issues may arise, affecting the valve's sealing performance.

Different types of wedge gate valve structures have distinct performance characteristics, making them suitable for various working conditions and media. When selecting a wedge gate valve, the first considerations should be the operating environment's temperature, pressure, and media properties. Flexible wedges are suitable for high-temperature environments with significant temperature fluctuations, avoiding jamming caused by temperature changes. Solid wedges are suitable for low-pressure, low-temperature applications but are prone to jamming at high temperatures. Double-disc wedges perform excellently in high-temperature and high-pressure environments, offering better sealing and durability, but their complex structure limits their applicability.

In summary, selecting the appropriate wedge gate valve and gate type should be based on actual working conditions, pipeline temperature, pressure, and media characteristics, while also considering maintenance convenience and service life. In high-temperature, low-temperature, and other special conditions, choosing the right gate type can significantly enhance the valve's performance and reliability.