Read the latest news on industrial valves and valve technologies. Here, you'll find updates on new products, helpful maintenance tips, and the latest trends in the industry. Whether you're interested in learning about new valve features, ways to keep your equipment running smoothly, or what's coming next in valve technology, we've got you covered with all the essential information.

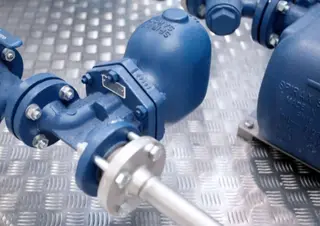

How to Properly Install Steam Traps: Complete Guide

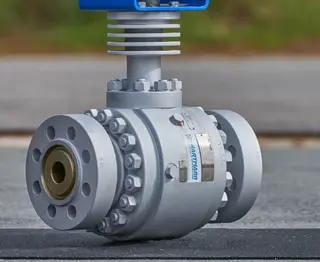

What is Explosion-Proof Electric Ball Valve

An Introduction to Ball Float Steam Traps for Steam Systems

Ball Float Steam Traps are vital for managing condensate and improving efficiency in steam systems. With a simple, durable design, they operate based on buoyancy, automatically discharging condensate while preventing steam leakage. Available in various types, they suit different industrial applications, ensuring optimal performance. Proper selection and maintenance enhance their reliability and energy-saving benefits, achieving significant cost reductions and environmental gains.

Guide to Diaphragm Pump Material Selection

Comparing Safety Valves and Pressure Reducing Valves

High-Temperature Ball Valves Material Selection

How to Choose the Right Electric Ball Valve?

Guide to Ball Valve Design: One-Piece, Two-Piece & Three-Piece

How to Choose the Right Gate Valves?

What's Triple-Offset Bidirectional Sealing Butterfly Valve?

Fully Welded Ball Valve: Guardian of Underground Pipelines

Cryogenic Valve Deep Cryogenic Treatment & Low-Temp Testing

Total 156 Records, 12 records per page